The beam storage system benefits a lot to garments and is consisted of various complex components, each part has its own corresponding function to make this machine work properly. This blog will explore the economic position of beam storage in the textile industry and the structure of the beam storage and the corresponding functions of each part.

The Economic Position of Beam Storage System

The economic position of beam storage systems in the textile industry is essential and highly advantageous for textile companies. These systems offer a wide range of benefits that can positively impact a company's bottom line, including cost savings, increased efficiency, improved profitability, scalability, flexibility, and enhanced safety.

1. Cost Savings

One of the key economic advantages of beam storage systems in the textile industry is cost savings. These systems optimize warehouse space by utilizing vertical storage, which allows textile companies to maximize their storage capacity and minimize the need for excessive floor space. This can result in significant cost savings in terms of reduced rental or ownership costs of large warehouse spaces. Additionally, beam storage systems provide efficient inventory management, which reduces the risk of damage or loss of inventory, minimizing replacement costs or write-offs. The organized and systematic storage provided by beam storage systems also reduces labor costs associated with inventory handling, as it improves accessibility to inventory and reduces the time and effort required to locate and retrieve textile rolls.

2. Increased Efficiency

Moreover, beam storage systems contribute to increased efficiency in the textile industry. The ability to adjust the height of beams and customize storage levels allows for efficient space utilization, minimizing wasted space and optimizing storage density. This can result in streamlined warehouse operations, as inventory is easily accessible and retrievable, reducing downtime and improving order picking efficiency. Beam storage systems can also be integrated with material handling equipment, such as forklifts or conveyors, to facilitate the seamless movement of inventory within the warehouse, further improving operational efficiency. Properly organized and easily accessible inventory in beam storage systems also reduces the risk of stockouts or overstock situations, improving overall inventory management and reducing associated costs.

3. Improved Profitability

Improved profitability is another significant economic benefit of beam storage systems in the textile industry. The cost savings in terms of reduced warehouse space, labor costs, and maintenance costs, coupled with increased operational efficiency, can lead to higher profitability through reduced operational expenses. The improved inventory management, resulting in reduced stockouts and overstock situations, can lead to higher customer satisfaction and increased sales, contributing to improved revenue and profitability. The durability and long-term performance of beam storage systems also minimize replacement costs, ensuring a higher return on investment over time. The overall improved efficiency, cost savings, and profitability associated with beam storage systems can provide textile companies with a competitive edge in the market, leading to increased market share and business growth.

4. Scalability and Flexibility

Scalability and flexibility are also key economic advantages of beam storage systems in the textile industry. These systems can be easily customized to meet the specific storage requirements of textile rolls, such as different sizes, weights, and materials. The adjustability of beams allows for flexible storage configurations, accommodating changing inventory needs and warehouse layouts. Beam storage systems can be easily expanded or reconfigured as the textile company's business grows or changes, providing scalability and adaptability to meet evolving storage requirements. This allows textile companies to optimize their storage space and inventory management processes as their business needs change, without incurring significant additional costs.

5. Enhanced Safety

Furthermore, enhanced safety is an important economic consideration in the textile industry, and beam storage systems are designed with safety features that contribute to a safer warehouse environment. Column protectors, end-of-aisle protectors, and rack guards are some of the safety features that are commonly incorporated into beam storage systems to prevent accidents and protect personnel and inventory. Properly installed beam storage systems provide stable and secure storage for textile rolls, minimizing the risk of inventory damage, falls, or collapses that can result in costly accidents and downtime. Enhanced safety in the warehouse environment helps to reduce workplace injuries, workers' compensation costs, and potential litigation, leading to cost savings and improved profitability.

The Structure of the Beam Storage System and the Corresponding Functions of Each Part

Beam storage systems, also known as pallet racking systems, are widely used in warehouses and distribution centers for efficient storage of goods on pallets. Here is an overview of the structure of a typical beam storage system and the functions of each part.

1. Uprights

Uprights are the vertical columns that form the main support structure of the beam storage system. They are typically made of steel and are designed to withstand heavy loads. Uprights are connected to the floor and the ceiling of the warehouse or distribution center and provide stability and strength to the entire system. They are available in various heights, widths, and depths to accommodate different storage requirements.

Functions of Uprights

l Provide vertical support for the entire beam storage system.

l Transfer the weight of the stored inventory and the beams to the floor.

l Distribute the load evenly across the system.

l Provide stability and rigidity to the system to ensure safe storage of inventory.

2. Beams

Beams are the horizontal load-bearing components that connect the uprights and support the pallets on which the inventory is stored. Beams are typically made of steel and are available in various lengths, capacities, and profiles to accommodate different storage needs. They are installed horizontally across the uprights at different levels, forming the levels or tiers of the storage system.

Functions of Beams

l Provide horizontal support for the pallets and the stored inventory.

l Transfer the weight of the inventory to the uprights and ultimately to the floor.

l Create the levels or tiers where the pallets are stored.

l Determine the height of the storage levels and the clearance between the levels.

3. Pallet Supports

Pallet supports are additional accessories that can be installed on the beams to provide additional support for the pallets and the inventory. They are typically made of steel and are designed to prevent pallets from sagging or falling through the beams.

Functions of Pallet Supports

l Provide additional support for the pallets to prevent sagging or falling through the beams.

l Enhance the load-bearing capacity of the beams, allowing for heavier loads to be stored on the pallets.

l Ensure that the pallets are evenly supported and properly positioned on the beams.

4. Wire Mesh Decking

Wire mesh decking is a common accessory that can be installed on the beams to create a stable and secure platform for storing non-palletized or small items. It is made of steel wires welded together to form a mesh pattern and is typically coated with a protective finish.

Functions of Wire Mesh Decking

l Provide a stable and secure platform for storing non-palletized or small items.

l Prevent smaller items from falling through the beams.

l Allow for easy visibility and access to the items stored on the decking.

l Enhance the safety of the storage system by preventing items from falling or shifting.

5. Column Guards

Column guards are protective accessories that can be installed around the uprights to prevent damage from forklifts or other equipment. They are typically made of steel and are designed to absorb impact and protect the uprights from accidental collisions.

Functions of Column Guards

l Protect the uprights from damage caused by forklifts or other equipment.

l Absorb impact and prevent dents or dings on the uprights.

l Enhance the safety of the storage system by preventing potential structural damage.

6. Row Spacers

Row spacers are accessories that can be installed between the uprights in a row to create a gap or space between the rows of the beam storage system. They are typically made of steel and are used to maintain proper spacing between the rows for easy access and efficient operation of the forklifts.

Functions of Row Spacers

l Provide structural stability to the entire storage system by connecting the upright frames horizontally and creating a rigid structure.

l Ensure that the distance between rows is maintained according to the required specifications, allowing for easy access to the inventory and efficient movement of material handling equipment.

l Prevent any potential damage or deformation of the upright frames due to uneven loading, ensuring that the storage system remains structurally stable and safe to use.

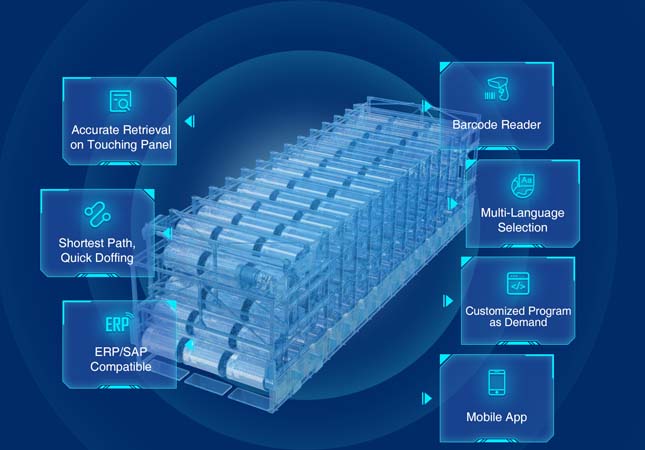

SUNTECH ST-BS Computerized Warp Beam Storage System ( Beam Stacker )

List of advanced features and benefits of SUNTECH model ST-BS for warp beam storage:

1. Extended Warranty

SUNTECH provides an unparalleled warranty extension for the Model ST-BS, instilling peace of mind and confidence in the system's durability and reliability.

2. Microprocessor-Controlled Information System

The ST-BS utilizes a cutting-edge microprocessor-controlled information system for precise storage and retrieval of specific beams. This advanced technology ensures efficient and accurate management of beam inventory.

3. Intelligentization

The system is equipped with intelligent features that enable the automated loading and unloading of beams. Using entered data such as beam number, beam code, and mill code, the ST-BS can automatically select the optimal path and bring the beam to the doffing position. Additionally, the system offers multi-language selection for ease of use.

4. HMI Touch Panel

The ST-BS features a high-quality touchscreen panel from the renowned French brand "Schneider," providing a user-friendly interface for easy access to data and machine operation. The intuitive touch panel enhances operational efficiency and convenience.

5. ERP Connection and Mobile App Control

The ST-BS seamlessly connects with an ERP system for data synchronization and sharing, enabling streamlined and efficient management of inventory. Additionally, the system can be controlled through a mobile app, providing remote access and monitoring for enhanced convenience and flexibility.

6. Chain Synchronization Automatic Detection Technology

The ST-BS is equipped with advanced chain synchronization automatic detection technology. If the chains on both sides of the beam stacker become out of sync, the system will sound an alarm and automatically stop running. This feature allows the operator to quickly assess and adjust the degree of tightness in the chains for optimal performance.

7. Versatile Integration

The SUNTECH Model ST-BS can be seamlessly integrated into various settings, including the weaving preparation workshop, weaving unit, and finishing unit, making it highly versatile for different stages of the textile production process.

Conclusion

In summary, the economic position of beam storage systems in the textile industry is highly favorable and it consists of several key components, each with its corresponding function, the SUNTECH Model ST-BS offers a cutting-edge solution for warp beam storage in the textile industry, with a range of advanced features and benefits.

SUNTECH textile machinery,as one of the leading textile machiner manufacturers, has always adhered to the value proposition of sustainable development, which is to help our customers achieve higher output with fewer resources by leveraging technology. We aim at empowering customer efficiency and productivity improvement, optimizing resource utilization,providing the textile industry machines to the whole world, such as fabric cutting machine,inspection machine,fabric inspection machine supply,automatic packing machine,auto packing machine,trolley lift system, fabric sample cutter machine, fabric roll cutting machine etc.