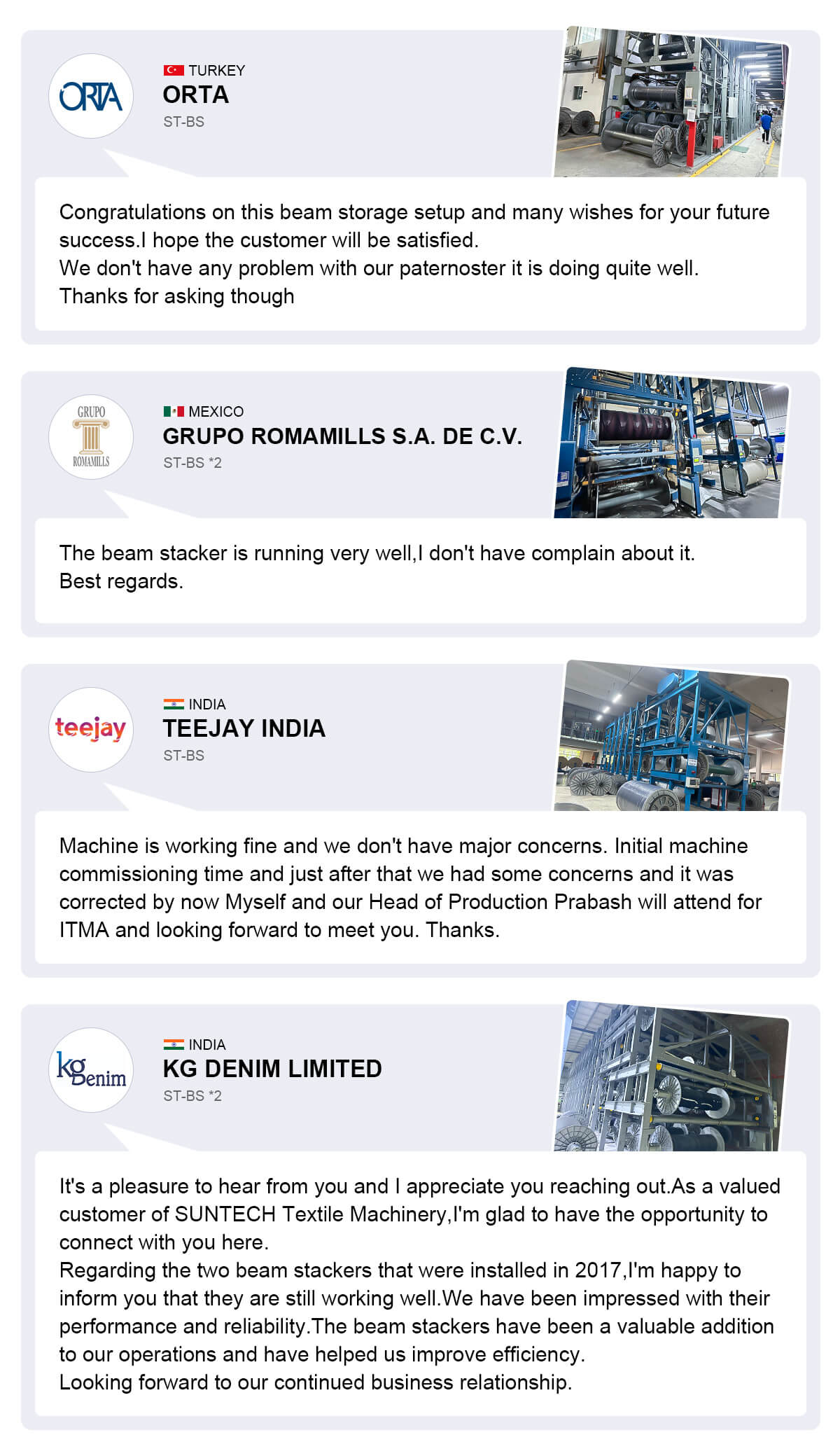

SUNTECH Computerized Warp Beam Storage System (Beam Stacker) is the Best Solution for Storage of Warp Beam/Size Beam/Weaving Beam/ Cloth Beam, Which are Widely Applicable in the Weaving Preparation Workshop, Weaving Unit and Finishing Unit for Space Utilization and to Avoid Damage of Ready Warp/Cloth Beam.

WARRANTY EXTENSION IS AVAILABLE AT SUNTECH THAN OTHER SUPPLIERS!

The Model ST-BS Could Employ a Microprocessor-Controlled Information System for Storage and Retrieval of Particular Beams.

Main Functions of ST-BS

1. Intelligentization

It can Intelligently Loading & Unloading Beam, the Automatic Beam Selection is Based on Entered Data Like Beam Number/Beam Code/Mill Code/etc, then ST-BS Will Selecting the Shortest Path and Bring the Beam at Doffing Position for You. Multi-language Selection is Also Available;

2. HMI (Touch Panel)

France “SCHNEIDER”Brand Touching Screen, for Easy and Quick Access of Data and Machine Operation;

3. ERP Connecting & Mobile App Controlling Available

It is available to Connect with ERP system to Realize Data Ssynchronization and Sharing. Also Can be Controlled by Mobile Software;

4. Chain Synchronization Automatic Detection Technology

When the Chains on Both Sides of Beam Stcaker are Out of Synchronous, ST-BS Will Alarm and Stop Running, then Operator Can Check Whether Bilateral Chains Need to Adjust the Degree of Tightness.