Meltblown machine gained immense popularity due to its unique properties and versatility which helps a lot in the process of production, and its ability to produce meltblown nonwoven fabric makes meltblown machine a critical machine in the textile industry. This blog will explore the basic connection of the meltblown nonwoven fabric between the meltblown machine.

Feature of Meltblown Nonwoven Fabrics

Meltblown nonwoven fabric is a type of high-performance filtration material that is widely used in various applications due to its exceptional properties. There are functions of the meltblown nonwoven fabric.

1. High filtration efficiency

The microfibers in meltblown fabric are extremely small, typically ranging in diameter from 0.1 to 10 microns, which is much smaller than the fibers in conventional spunbond or needle-punched nonwoven fabrics. This fine fiber structure allows for a much higher surface area per unit weight, resulting in a fabric with excellent filtration performance. Meltblown nonwoven fabric is capable of capturing small particles, including bacteria, viruses, fine dust, and airborne pollutants, making it ideal for use in applications such as medical masks, respirators, air filters, and liquid filtration.

2. High breathability

The fine fiber structure of meltblown fabric creates a porous network with a small pore size, allowing air to pass through easily while trapping particles. This makes meltblown fabric highly breathable and comfortable to wear in applications where breathability is important, such as in medical masks or other personal protective equipment (PPE).

3. Excellent liquid repellency and absorption

The hydrophobic nature of many polymer materials used in meltblown fabric, such as polypropylene, allows it to repel liquids, making it suitable for use in applications where liquid barrier properties are required, such as in oil-absorbent mats or protective clothing. On the other hand, meltblown nonwoven fabric can also be treated with special coatings or additives to make it hydrophilic, enabling it to absorb and retain liquids, which is useful in applications such as wound dressings or absorbent pads.

SUNTECH Meltblown Machine Helps Nonwoven Fabrics Production

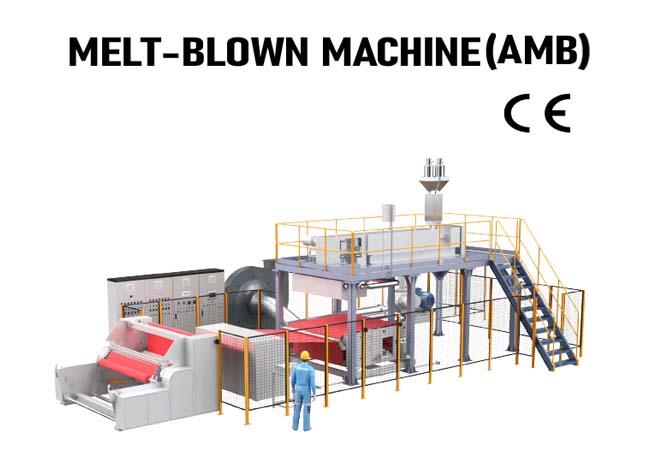

SUNTECH ST-AMB meltblown machine(AMB)

SUNTECH offers non-woven fabric slitting machines and premium meltblown machines for the production of high-quality meltblown nonwovens.

1. These machines are widely used in filtration and medical fields due to their excellent filterability and barrier properties.

2. The machines ensure strong stability and considerable productivity, allowing for easy setup and operation.

3. In industries like medical protection, strict standards for filterability are required, especially for materials used in medical and surgical face masks.

4. SUNTECH's meltblown lines ensure top-class filterability for bacteria and viruses, providing worry-free quality and production stability.

5. Using SUNTECH's machines can make you a reliable and sought-after supplier in the market quickly, as they help meet strict standards and produce high-quality meltblown nonwovens.

Conclusion

In conclusion, the meltblown nonwoven machine, equipped with unique functions and advantages, is widely used in our daily life. The meltblown machine enables the creation of fine, randomly interconnected fibers that form the dense and porous structure characteristic of meltblown fabric because of its perfect structure and variety of advantages. And the SUNTECH ST-AMB meltblown machine, which has lots of advantages, would be an ideal choice for manufacturers in the textile industry.

As a reputable textile machinery manufacturer with a rich history in automation and intelligent manufacturing technology of textile and warehousing equipment, SUNTECH Textile Machinery possesses cutting-edge core technologies that are recognized globally.

SUNTECH’s products cover the textile manufacturing and handling process of almost fabric types, in which pinking machine, non woven machine, beam truck, meltblown machine, fabric cutting machine, motorized beam trolley, beam storage, warp tying machine are the most popular machines and material handling equipment.

SUNTECH Textile Machinery leads the textile industry with our innovation and experience! Quotes and Cooperation are Highly Welcome!