The textile industry is one of the oldest industries in the world and has come a long way since the first weaving machines were invented in the 18th century, over the years, we have seen significant advancements in textile machinery, from the first spinning and weaving machines to modern. Today, textile machinery is highly advanced, with many machines incorporating intelligent and AI computer technology to improve efficiency, accuracy, and quality. As a textile machinery supplier that has provided high-quality products for customers, SUNTECH Textile Machinery will follow the future trends and keep going on.

Future Development Trends of Textile Machinery

According to the information and the development trends of the textile industry, we have summarized the following trends.

1. Sustainability

The textile industry is increasingly concerned about the environmental impact of its operations and is looking for ways to reduce waste, and water consumption, and adopt eco-friendly production processes. Textile machinery manufacturers are also focusing on developing more sustainable machines that consume less energy, produce less waste, and have a lower environmental footprint. We can expect to see more innovative and sustainable solutions being developed for textile machinery in the future.

2. Automation

The use of robotics, artificial intelligence (AI), and machine learning is transforming the textile industry. These technologies are helping textile manufacturers to automate various processes, such as cutting, sewing, weaving, and spinning, leading to improved efficiency, productivity, accuracy, and reduced labor costs. Intelligent machines capable of carrying out complex tasks autonomously are expected to become more common, reducing the need for human intervention.

3. Digitalization

Digital technologies like 3D printing, computer-aided design (CAD), and virtual prototyping are revolutionizing the textile industry. They allow textile manufacturers to create and test new designs quickly and efficiently. Digitalization also improves supply chain management and waste reduction by enabling accurate tracking of materials and products. There is an exception to see more textile machinery that integrates digital technologies, leading to greater efficiency and accuracy in production.

4. Smart Textiles

Smart textiles are textiles that have embedded sensors, microchips, and other electronic components that can monitor and adjust to changes in the environment. They have several potential applications, from wearable technology to medical textiles. Textile machinery manufacturers are developing machines that can produce smart textiles, and we can expect to see more innovations in this area in the future.

5. Personalization

Consumers are increasingly demanding customized products that cater to their individual needs and preferences. Textile machinery manufacturers are developing machines that can produce customized textiles quickly and efficiently, allowing for greater flexibility in production. More textile machinery capable of producing small batches of customized products is expected to emerge, enabling textile manufacturers to respond to changing consumer demands more quickly.

6. Circular Economy

The circular economy is an economic model that aims to reduce waste and promote sustainability by keeping products and materials in use for as long as possible. The textile industry is adopting circular economy principles by exploring ways to reuse and recycle textile waste. Textile machinery manufacturers are also developing machines that can process textile waste into new materials, reducing the environmental impact of textile production. We can expect to see more innovation in this area in the future as the textile industry seeks to minimize its environmental footprint.

Intelligent and AI Computer Technology in Textile Machinery

l Intelligent textile machinery uses sensors and control systems to monitor and adjust the production process in real time. This allows for more precise control of factors such as temperature, humidity, and tension, which can significantly improve the quality of the finished product. For example, in the spinning process, intelligent machines can detect and correct any inconsistencies in the fiber length or diameter, ensuring that the yarn produced is of consistent quality.

l Another area where AI computer technology is making a big impact in textile machinery is in the design and production of textiles. With the help of machine learning algorithms, designers can create complex patterns and designs that were previously difficult or impossible to achieve manually. These algorithms can analyze large data sets of past designs and create new ones that are similar in style or pattern. This can help textile companies quickly create new designs that are in line with current fashion trends.

l AI computer technology is also being used to improve the efficiency of textile machinery. By analyzing data from sensors and control systems, machine learning algorithms can identify areas where the production process can be optimized. For example, they can detect bottlenecks in the production line and suggest ways to improve workflow or reduce downtime. They can also predict when equipment will need maintenance, allowing for preventative maintenance to be performed before a breakdown occurs.

l One of the most significant advantages of using intelligent and AI computer technology in textile machinery is that it can help to reduce waste and improve sustainability. By monitoring and controlling factors such as temperature, humidity, and tension, machines can reduce the amount of raw material needed to produce a given product, which not only reduces costs but also reduces the environmental impact of the production process. Additionally, AI computer technology can help to identify areas where energy consumption can be reduced, further improving the sustainability of the textile industry.

l Finally, there are concerns about the impact of AI computer technology on jobs in the textile industry. While these technologies can improve efficiency and reduce costs, they may also lead to job losses as machines take over tasks that were previously performed by humans. The industry will need to carefully manage this transition to ensure that workers are not left behind.

Conclusion

The textile industry is set to undergo significant changes in the coming years, with new trends emerging that will transform the way textiles are produced. As technology continues to evolve, we can expect to see more intelligent machines that are capable of producing high-quality textiles more efficiently and sustainably than ever before. By carefully managing this transition, the textile industry can reap the benefits of intelligent and AI computer technology while minimizing the impact on workers.

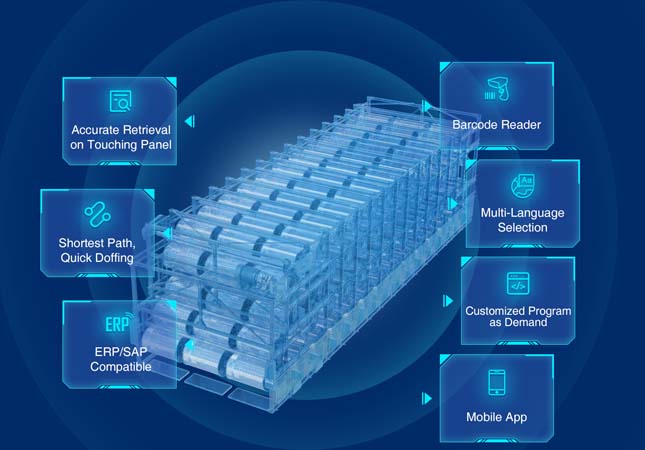

As a reputable textile machinery manufacturer with a rich history in automation and intelligent manufacturing technology of textile and warehousing equipment, SUNTECH Textile Machinery possesses cutting-edge core technologies that are recognized globally.

SUNTECH’s products cover the textile manufacturing and handling process of almost fabric types, in which non woven machine, meltblown machine, fabric cutting machine, motorized beam trolley, beam storage, warp tying machine are the most popular machines and material handling equipment.

SUNTECH Textile Machinery leads the textile industry with our innovation and experience! Quotes and Cooperation are Highly Welcome!