Our country is largest producer and exporter of textiles and garments in the world, so our country attaches great importance to the textile industry. The rapid development of the textile industry and the improvement of production efficiency are inseparable from the use of textile machinery. In the textile industry, the loom beam is an indispensable part of the entire textile process, and the beam transport trolley used to transport the beam is also essential. So loom beam and beam transport trolley are the most indispensable combination in the textile industry.

Generally speaking, according to the process flow of the weaving factory, the loom beam can be divided into Warp Beam and Weaving Beam. In the weaving mill, the yarn goes through a series of processes into the final fabric. During this working process, when warping, we need to use the warping beam, and when weaving, that is, the shaft used on the loom, we call it the weaving beam. Warping is the process of winding a certain number of warp yarns in parallel on the warp beam or weaving beam according to the specified length and width. The warp yarns that have been warped are used for sizing and warp threading. As for weaving, this is to make the warp and weft yarns show a specific pattern according to a certain rule according to the weaving design organization chart provided by the fabric designer.

Therefore, the frequency of use of the beam in the weaving factory is very high, so the transport of the beam in the weaving factory can also effectively improve the production efficiency. Suntech have various of beam transport trolley.

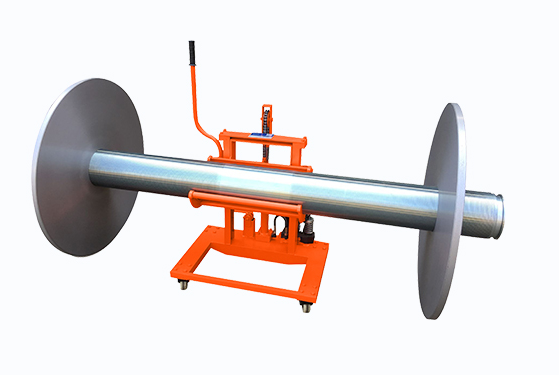

empty warp beam transport trolley

ST-MBT-09

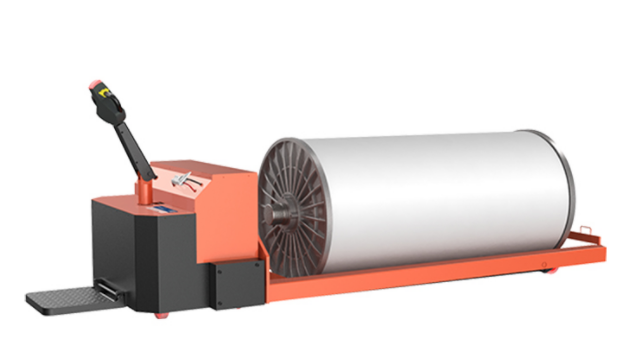

And SUNTECH beam transport trolley divided into hydraulic models and electric models. The Electric Warp Beam Low Lift Trolley is designed for the easy transport of warpers’ beams and warp beams weighing up to 2000kg which is also suitable for longer distances, e.g. from the warping frame to the warping machine or to the warehouse. Depending on the beam length and beam diameter, the trolley is also able to handle grades while transporting loads. Sensitive driving and braking action make it an easy transport. The central drive provides good traction and the spring-loaded wheels ensure good and safe driving characteristics.

And we have Electronic Power Steering, which can help operator use this trolley easily, Electric Steering System uses motor to control the drive wheels instead of manpower to turn the drive wheels.When need to adjusts the direction of trolley, the operator only needs to turn the handle lightly.The required manpower is only one fifth of the mechanical steering. The principle is same as car steering system, which really saves efforts and improves working efficiency.

As for the drive of trolley, SUNTECH use AC motor and GEL battery.

Why we use AC motor not DC motor?

A: AC motor’ s structure is simple, while DC motor is complex

B: AC motor’ s Maintenance requirements is free, no need to maintain, while DC motor need to maintain with carbon brushes, need regular maintenance, high costs.

C: Efficiency&capacity. AC motor is high efficiency, large power range. While DC motor is limited speed, limited capacity.

D: Environmental performance. AC motor is no smoke, no pollution, low noise. While DC motor has generate spark during operation, short lifetime.

What is the advantage of GEL battery?

A: Gel battery’ s Maintenance requirements is free, no need balanced charging, while lead acid battery need adding electrolyte regularly, need balanced charging regularly.

B: Gel battery’ s working life is twice of lead acid battery. Lead acid battery can only charge 500 times.

C: Charging time. Gel battery’ s Charging time usually 3-4 hours, only 2-3 hours under 0.8-1.5CA fast charging. Fast charging does not affect battery life. While lead acid battery’ s charging time usually 12 hours.

D: Self-discharge time. Gel battery is convenient for long-term storage, after 1 year of storage at normal temperature, the capacity retention rate can still reach 90%, storing for 2 years at 20 ° C temperature, it can be put into operation without charging. As for lead acid battery, after 180 days of storage at 20°C environment, a deeply charging is required, otherwise the battery would be damaged.

E: Full charge and discharge capability. Gel battery can be reused again after several minutes when power is off, which is especially beneficial for emergency use. While lead acid battery has to charge again.

F: Self-recovery. Gel Battery is more stable under high load, while lead acid battery is bot good under high load.

G: Environmental performance. Gel Battery is environmental protection(No pollution), the electrolyte can be used as fertilizer, the battery grid can be recycled. As for lead acid battery, it needs special treatment to avoid environment pollution.

SUNTECH is a professional worldwide enterprise with decades of experience and research. We are committed to providing customers with excellent products and customized service. Our experienced experts will offer customers timely and effective integrated services in pre-sales consultation, sales, maintenance, and comprehensive after-sales support, giving customers the ultimate and comprehensive service experience.