Beam storage systems, also known as pallet racking systems, can streamline inventory management processes in various ways, leading to more efficient and effective warehouse operations, can also provide a controlled environment for stored inventory in a warehouse or distribution center.

The Ways of Beam Storage Streamline Inventory Management Processes

Here are some ways how beam storage systems can streamline inventory management processes:

1. Increased Storage Capacity

Beam storage systems are designed to maximize vertical space utilization in warehouses, allowing for higher storage capacity compared to other storage methods, which helps to increase storage capacity which means that more inventory can be stored in a smaller footprint, reducing the need for additional warehouse space or expansion. By utilizing the height of the warehouse, beam storage systems help streamline inventory management by providing ample space for storing a large quantity of inventory, reducing stockouts, and ensuring efficient replenishment.

2. Easy Visibility and Accessibility

Beam storage systems provide clear visibility and easy accessibility to stored inventory, making it easier for warehouse personnel to locate and retrieve items. With selective racking, where each pallet or item is directly accessible, warehouse personnel can quickly identify and retrieve the required inventory, reducing the time and effort spent on searching for items, streamlined accessibility helps improve inventory management processes by reducing delays in order fulfillment, minimizing handling errors, and improving overall warehouse productivity.

3. Customized Configurations

Beam storage systems can be customized to meet the specific requirements of different types of inventory. For example, textile rolls, fragile items, or perishable goods may have unique storage needs. Beam storage systems can be configured with specialized accessories such as supports, cradles, or dividers to properly store and protect different types of inventory, customized configuration helps streamline inventory management processes by ensuring that inventory is stored in a manner that maximizes space utilization, minimizes damage or spoilage, and facilitates easy retrieval and replenishment.

4. FIFO and Stock Rotation

Beam storage systems are a tool to facilitate proper stock rotation and adherence to the "first-in, first-out" (FIFO) principle, ensuring that older inventory is used before newer inventory, minimizing the risk of obsolescence, spoilage, or expiration. Techniques such as push-back racking or gravity flow racking can be employed to automatically facilitate FIFO, where inventory is loaded from one side and retrieved from the other side, ensuring that the oldest inventory is used first, streamlined stock rotation helps improve inventory management processes by reducing the risk of inventory obsolescence, improving product quality, and minimizing inventory holding costs.

5. Efficient Replenishment Processes

Beam storage systems can streamline replenishment processes by providing clear visibility of inventory levels and facilitating efficient restocking. Warehouse personnel can easily monitor inventory levels and identify areas that require replenishment, allowing for timely replenishment activities. With proper organization and labeling of inventory within the beam storage system, warehouse personnel can quickly locate and retrieve replenishment items, reducing the time and effort spent on restocking, helping improve inventory management processes by ensuring optimal inventory levels, reducing stockouts, and improving overall warehouse productivity.

6. Integration with Inventory Management Systems

Beam storage systems can be integrated with inventory management systems, such as warehouse management systems (WMS) or enterprise resource planning (ERP) systems, to further streamline inventory management processes. The integration allows for real-time visibility of inventory levels, locations, and movements, facilitating accurate inventory tracking and management. Warehouse personnel can easily update inventory information in the inventory management system as items are received, stored, or retrieved from the beam storage system, ensuring accurate inventory counts and reducing the risk of stockouts or overstock situations, integrated approach helps improve inventory accuracy, reduces manual data entry errors, and streamlines inventory management processes.

7. Improved Safety and Security

Beam storage systems are designed with safety features such as load capacity limits, upright protectors, and beam connectors to ensure safe storage and handling of inventory, and reduce the risk of accidents, injuries, and damage to inventory.

How Beam Storage Systems Provide a Controlled Environment

A controlled environment refers to an environment where certain conditions, such as temperature, humidity, or air quality, are maintained within specified limits to protect the integrity and quality of the stored inventory. Here are some ways how beam storage systems can provide a controlled environment:

1. Climate-Controlled Storage

Beam storage systems can be installed in climate-controlled areas of the warehouse, where temperature and humidity are regulated to meet the specific requirements of the stored inventory. Climate-controlled storage is particularly important for items that are sensitive to temperature or humidity fluctuations, such as perishable goods, pharmaceuticals, or electronics. Beam storage systems can be installed in temperature-controlled rooms or areas equipped with HVAC systems to maintain a consistent environment, protecting the quality and integrity of the inventory. This controlled environment helps prevent spoilage, damage, or degradation of the inventory, ensuring that it remains in optimal condition until it is ready for shipment or use.

2. Enclosed Storage

Beam storage systems can be enclosed with additional accessories, such as wire mesh panels or plastic curtains, to create a controlled environment within the storage system. These enclosures can help protect the stored inventory from dust, debris, and other contaminants that may be present in the warehouse environment. Enclosed storage can also prevent unauthorized access to the inventory, ensuring security and reducing the risk of theft or damage, controlled environment created by the enclosure helps maintain the quality and integrity of the inventory, particularly for sensitive or valuable items.

3. Specialized Storage Accessories

Beam storage systems can be equipped with specialized storage accessories that provide a controlled environment for specific types of inventory. For example, roll-up doors, sliding doors, or strip curtains can be installed on the front of the pallet racking system to create a controlled environment for items that require protection from dust, dirt, or other contaminants. These specialized storage accessories can be easily opened or closed as needed, allowing for easy access to the inventory while maintaining a controlled environment, so that the inventory remains in optimal condition and is protected from environmental factors that may affect its quality or integrity.

4. Inventory Segregation

Beam storage systems can facilitate inventory segregation, which can help maintain a controlled environment for certain types of inventory. Inventory segregation involves keeping different types of inventory separate from each other to prevent cross-contamination or damage. For example, hazardous materials, chemicals, or food products may require segregation from other inventory to prevent contamination. Beam storage systems can be configured with specialized accessories, such as dedicated bays or shelves, to segregate different types of inventory, ensuring that they are stored in a controlled environment without being exposed to potentially harmful substances or conditions.

5. Monitoring and Alarm Systems

Beam storage systems can be integrated with monitoring and alarm systems to provide real-time monitoring of the environment within the storage system. Sensors can be installed to measure temperature, humidity, air quality, or other relevant parameters, and connected to a centralized monitoring system, allowing warehouse personnel to monitor the environment within the beam storage system and receive alerts or alarms if the conditions go outside of the specified limits. Monitoring and alarm systems can help ensure that the controlled environment is maintained at all times, allowing for timely corrective actions to be taken if necessary.

6. Proper Maintenance and Cleaning

Beam storage systems require regular maintenance and cleaning to ensure that they continue to provide a controlled environment for the stored inventory. Regular maintenance activities, such as inspections, repairs, or replacements of damaged components, can help ensure that the beam storage system remains in good condition and does not compromise the controlled environment. Proper cleaning of the storage system, including the uprights, beams, and accessories, can help remove dust, dirt, or other contaminants that may affect the quality of the stored inventory.

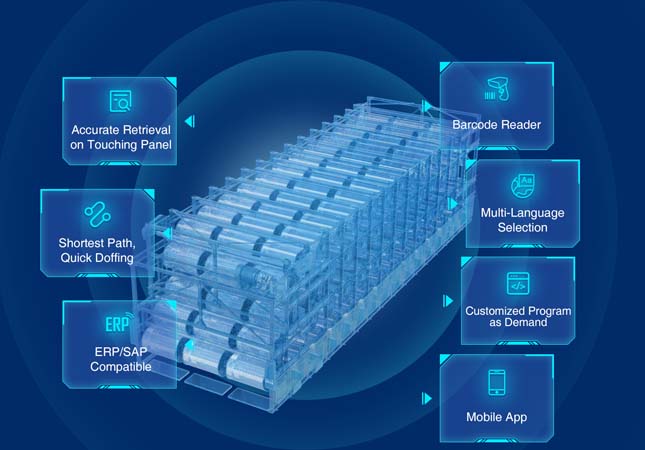

SUNTECH ST-BS Computerized Warp Beam Storage System ( Beam Stacker )

SUNTECH computerized warp beam storage offers unparalleled solutions for storing various types of beams, such as warp beams, size beams, weaving beams, and cloth beams. This cutting-edge system is highly versatile and can be seamlessly integrated into various settings, including the weaving preparation workshop, weaving unit, and finishing unit.

Advanced Features and Benefits of SUNTECH Model ST-BS:

1. Extended Warranty

SUNTECH provides a superior warranty extension for the Model ST-BS, ensuring peace of mind and confidence in the durability and reliability of the system.

2. Microprocessor-Controlled Information System

The ST-BS utilizes a state-of-the-art microprocessor-controlled information system for precise storage and retrieval of specific beams. This advanced technology ensures efficient and accurate management of beam inventory.

3. Intelligentization

The system is equipped with intelligent features that allow for the automated loading and unloading of beams. Based on entered data such as beam number, beam code, and mill code, the ST-BS can automatically select the optimal path and bring the beam to the doffing position. Additionally, the system offers a multi-language selection for ease of use.

4. HMI Touch Panel

The ST-BS features a high-quality touchscreen panel from the renowned French brand "Schneider," providing a user-friendly interface for easy access to data and machine operation. The intuitive touch panel enhances operational efficiency and convenience.

5. ERP Connection and Mobile App Control

The ST-BS can seamlessly connect with an ERP system for data synchronization and sharing, enabling streamlined and efficient management of inventory. Additionally, the system can be controlled through a mobile app, providing remote access and monitoring for enhanced convenience and flexibility.

6. Chain Synchronization Automatic Detection Technology

The ST-BS is equipped with advanced chain synchronization automatic detection technology. If the chains on both sides of the beam stacker become out of sync, the system will sound an alarm and automatically stop running. This feature allows the operator to quickly assess and adjust the degree of tightness in the chains for optimal performance.

Conclusion

In summary, beam storage systems streamline inventory management processes, leading to increased operational efficiency and productivity in the textile industry, they also provide a controlled environment that protects textile materials from adverse conditions such as moisture, dust, and sunlight, helping to preserve their quality and durability, which is crucial for maintaining the integrity of textile products, the SUNTECH Model ST-BS offers a cutting-edge solution for warp beam storage in the textile industry, with a range of advanced features and benefits.

SUNTECH provides the textile industry machines to the whole world, helps them to improve the efficient, decrease the labor costs. SUNTECH offers numerous types of textile machinery: visual inspection defects, fabric measure and cutting machine, fabric swatch cutter, beam truck, trolley lift system, fabric roll cutting machine etc. If you are interested in us, please contact us now!