In the world of textiles, a quiet revolution is underway, one that is driven by the remarkable properties of nanomaterials. When substances are scaled down to the nanoscale, they undergo profound transformations in their physical and chemical characteristics. This revolution in functional materials is reshaping the textile industry, not only in terms of technological advancements but also in the pursuit of sustainable development.

Nanomaterial Transformations:

At the heart of this transformation lies the power of nanoscale materials. For instance, copper, a traditionally conductive material, loses its conductivity at the nanoscale. Conversely, nanoscale ceramics become remarkably resistant to fractures and can even bend. These alterations in optical, electrical, thermal, and magnetic properties, along with novel characteristics like absorption, catalysis, and adsorption, are fundamentally reshaping the industrial landscape.

Applications of Functional Fibers:

The integration of nanotechnology into the textile industry is continuously evolving, offering exciting opportunities to enhance the performance and functionality of textiles. By combining specially engineered nanomaterials with textile raw materials, a new generation of functional fibers has emerged, boasting properties such as antibacterial qualities, self-cleaning abilities, flame retardancy, and infrared absorption.

Two primary areas of focus in nanotechnology for textiles have emerged:

Nanofibers: These ultrafine fibers, with diameters smaller than 100 nanometers, bridge the gap between the nanoscale and macroscopic worlds. Their increased surface area-to-volume ratio offers superior filtration efficiency, making them ideal for various applications.

Nanoscale Particle Integration: Functional nanomaterials, such as antibacterial agents, flame retardants, and electromagnetic shields, are directly incorporated into fibers. Techniques include single-walled or multi-walled carbon nanotube bundles and various spinning methods, resulting in fiber diameters ranging from 10 to 100 nanometers.

Textile Finishing with Nanotechnology:

China has pioneered nanomaterial technology that prevents direct contact between liquids like oil and water with textile surfaces. Fabrics treated with this technology become water and oil repellent, resist substances like ink and lemon juice, and offer additional benefits such as antibacterial properties and radiation protection. Crucially, these treated fabrics retain their original properties like fiber strength, dye affinity, breathability, and skin-friendliness.

This breakthrough has the potential to revolutionize laundry habits, reducing the need for extensive water washing. When washing is necessary, minimal water usage is sufficient, leading to significant water savings and reduced environmental pollution from wastewater discharge.

The Future of Nanomaterials in Textiles:

Nanomaterials and nanocomposites developed in the textile field have demonstrated outstanding performance, offering exciting prospects for the future. As nanoparticle production costs decrease and the variety of functional nanoparticles expands, these materials will find widespread applications not only in textiles but also across various industries, promising a sustainable and innovative future.

Conclusion:

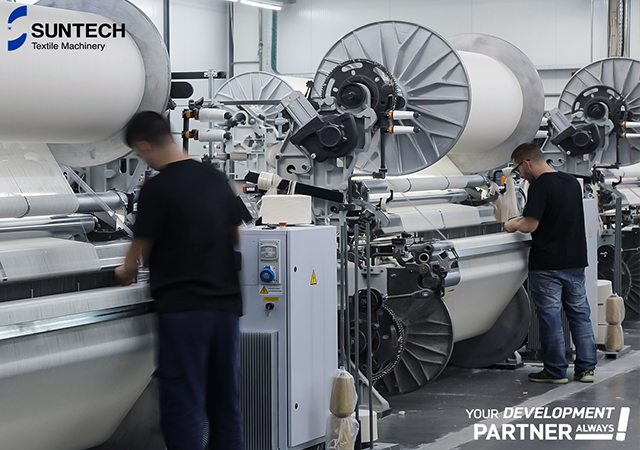

The functional material revolution in textiles, driven by nanomaterials and cutting-edge technologies, is ushering in a new era of performance and sustainability. As we witness the convergence of science, industry, and environmental consciousness, the textile industry is embracing this revolution with open arms. SUNTECH Textile Machinery is a distinguished manufacturer of textile machinery with a rich legacy of automation and intelligent manufacturing technology for textile and warehousing equipment. SUNTECH's state-of-the-art core technologies have garnered global recognition.

SUNTECH Textile Machinery has the range of products encompasses almost all fabric types, including but not limited to loom machine, fabric cutting machine, motorized beam trolley, beam storage, and fabric inspection machine. We will continue to lead the textile industry with its innovative approach and extensive experience.