Automatic packaging machine help to speed up the process, minimize errors, and reduce labor costs. However, like any other machine, the machine can experience technical problems that can impact its performance and efficiency. Identifying and fixing these problems can help ensure that the machine operates optimally, reducing downtime and enhancing productivity. This blog will explore how to identify and fix common problems with the automatic packaging machine.

How to Identify and Fix Automatic Packaging Machine Problems

Here are some common problems of automatic packaging machines and how to fix the machine.

1. Poor or Inconsistent Seal Quality

One of the most common problems with automatic packaging machines is poor or inconsistent seal quality. Poor seals can lead to product damage or contamination, and inconsistent seals can impact the quality and safety of the packaged product. Poor or inconsistent seal quality can be caused by various factors, including:

a) Insufficient Heat or Pressure

Insufficient heat or pressure can cause the seal to be weak or incomplete, leading to poor seal quality. To fix this problem, ensure that the machine's heating element and pressure settings are calibrated correctly and that the sealing components are in good condition.

b) Worn or Damaged Sealing Components

Worn or damaged sealing components such as blades, jaws, or sealing bars can cause poor seal quality. To fix this problem, replace the worn or damaged components and ensure that they are correctly aligned.

c) Incorrect Sealing Temperature or Dwell Time

The sealing temperature and dwell time play a crucial role in ensuring proper seal quality. If the temperature or dwell time is too high or too low, it can cause poor or inconsistent seal quality. To fix this problem, adjust the temperature and dwell time settings to the manufacturer's recommended specifications.

2. Jammed or Misaligned Products

Another common problem with automatic packaging machines is jammed or misaligned products. This can occur when the product is not properly fed into the machine, or when the machine's components are not correctly aligned. Jammed or misaligned products can cause downtime and reduce the machine's efficiency. Some possible causes of jammed or misaligned products include:

a) Incorrect Product Feeding

Incorrect product feeding can cause jams or misaligned products. To fix this problem, ensure that the product is correctly fed into the machine and that the feeding mechanism is working correctly.

b) Worn or Damaged Components

Worn or damaged components such as belts, rollers, or guides can cause misaligned products. To fix this problem, replace the worn or damaged components and ensure that they are correctly aligned.

c) Incorrect Machine Calibration

Incorrect machine calibration can also cause jammed or misaligned products. To fix this problem, calibrate the machine according to the manufacturer's recommended specifications.

3. Machine Stops or Shuts Down

Automatic packaging machines may stop or shut down unexpectedly, causing downtime and reducing efficiency. Some possible causes of machine stops or shutdowns。

a) Power Failure

Power failure can cause the machine to stop or shut down. To fix this problem, ensure that the machine is connected to a stable power source and that the power supply is uninterrupted.

b) Overheating

Overheating can cause the machine to shut down to prevent damage. To fix this problem, ensure that the machine is correctly ventilated and that the cooling system is working correctly.

c) Faulty Sensors

Faulty sensors can cause the machine to stop or shut down unexpectedly. To fix this problem, replace the faulty sensors and ensure that they are correctly calibrated.

4. Excessive Noise or Vibration

Excessive noise or vibration can be a sign of mechanical problems with the machine. Some possible causes of excessive noise or vibration.

a) Loose Components

Loose components such as screws, nuts, or bolts can cause excessive noise or vibration. To fix this problem, ensure that all components are correctly tightened and that there are no loose parts.

b) It may be coming from the motor, the belts, the gears, or any other part of the machine. You can use a stethoscope or a vibration meter to pinpoint the source of the noise or vibration.

c) Worn-out or damaged parts can also cause excessive noise or vibration. Check for any worn-out or damaged parts within the machine, such as bearings, belts, or pulleys. Replace these parts as necessary.

SUNTECH ST-ARPM Automatic Fabric Roll Packing Machine( Linear Fabric Inspection and Packing Line )

Features and benefits of SUNTECH ST-ARPM automatic fabric roll packing machine.

1. Efficient Fabric Roll Packing

The SUNTECH ST-ARPM is a vacuum and automatic packing machine designed to pack fabric rolls efficiently, reducing labor needs and time consumption.

2. Certified Quality and Safety

The machine meets the European CE standard, ensuring its quality and safety, and providing peace of mind to users.

3. Extended Warranty

SUNTECH offers a longer warranty extension for the ST-ARPM, exceeding what other suppliers provide, giving users more confidence and support.

4. Fully Automated Operation

The ST-ARPM has fully automated operation as its main function, reducing the need for labor and providing a vacuum packing effect for better protection, increasing efficiency.

5. Environmentally Friendly

The ST-ARPM saves materials compared to traditional plastic bag packaging methods, making it a more environmentally friendly option and reducing the impact on the environment.

Conclusion

In conclusion, understanding the common problems that the machine face and knowing how to identify and fix them is helpful for the manufacturers to save time and money, avoid production downtime, and maintain high-quality products. Some common problems that operators may encounter include issues with the machine's electrical and mechanical components, problems with sensors and switches, and difficulties with packaging materials. With proper care and attention, automatic packaging machine can provide reliable and efficient packaging solutions for many years.

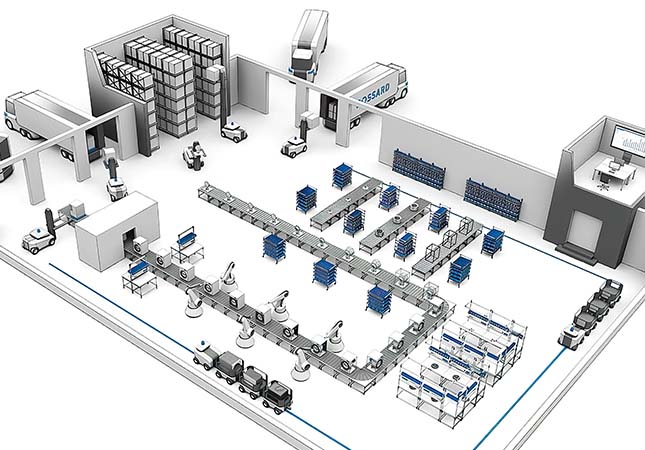

SUNTECH Textile Machinery is a distinguished manufacturer of textile machinery with a rich legacy of automation and intelligent manufacturing technology for textile and warehousing equipment. SUNTECH's state-of-the-art core technologies have garnered global recognition.

SUNTECH Textile Machinery has the range of products encompasses almost all fabric types, including but not limited to pinking machine, non-woven machine, beam truck, meltblown machine, fabric cutting machine, motorized beam trolley, beam storage, and fabric inspection machine. SUNTECH Textile Machinery continues to lead the textile industry with its innovative approach and extensive experience. We welcomes quotes and cooperation opportunities with open arms.