As technology continues to advance, so does the variety of ways it can be used in many industries. In the textile industry, automation is becoming increasingly important when it comes to fabric inspection machine. This article will discuss how these machines can revolutionize the way fabrics are inspected and what advantages they have over traditional methods. So if you're looking for efficient and reliable fabric inspections, keep reading to find out more!

Introduction: What is Automation in the Fabric Inspection Machine?

Automation in the fabric inspection machine is the process of using machines to perform tasks that would otherwise be completed by humans. This can include tasks such as weaving, cutting, and sewing fabric. Automation can help to improve productivity and efficiency in the fabric inspection process, as well as reduce errors and waste.

Benefits of Automation in the Fabric Inspection Machine

There are many benefits of automation in the fabric inspection machine. When a fabric is automatically inspected, it can be done so much more quickly and accurately than if it were done by hand. This means that you can get your products to market faster, with fewer defects.

In addition, automated fabric inspection can help to improve safety in the workplace. Manual inspection of fabrics can be dangerous, as it often involves working with sharp tools and chemicals. Automated inspection removes the need for workers to handle these dangerous materials, instead relying on machines to do the work safely.

Finally, automated fabric inspection can also help to reduce costs in the long run. Once you have invested in an automated system, it will pay for itself many times over in terms of increased efficiency and accuracy.

Different Types of Automated Inspections for Fabrics

1. Manual Inspection

The most common form of fabric inspection is manual inspection. In this type of inspection, a person uses their eyes and hands to inspect the fabric for any defects. This method is very slow and can be prone to human error.

2. Optical Fabric Inspection

Optical fabric inspection is a type of automated inspection that uses sensors to detect defects in the fabric. This method is much faster than manual inspection and can be more accurate.

3. SUNTECH Automatic Camera Fabric Inspection System

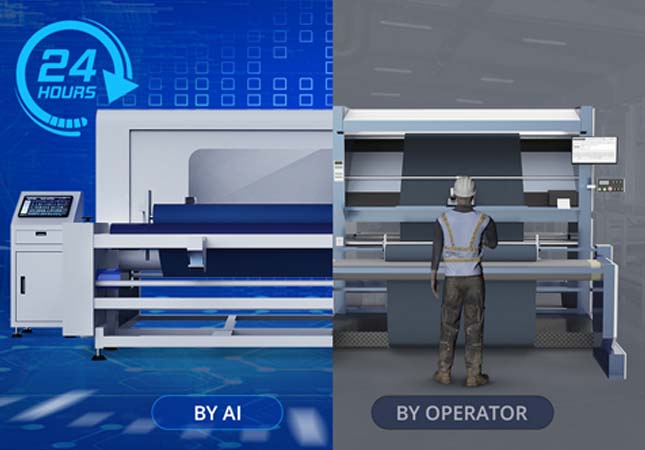

SUNTECH Automatic Camera Fabric Inspection System is a type of automated inspection that uses camera to detect defects in the fabric. SUNTECH's automatic camera inspection machine has AI deep learning technology for quality fabric inspection, achieving 24-hour unmanned testing, and its 60m/min max speed enables you to save 5 times labor cost by 5 times. And at an excellent price!

How to Choose the Right Automated Fabric Inspection System

When it comes to choosing the right automated fabric inspection system for your business, there are a few things you need to take into account. The following guide will help you choose the best system for your needs:

1. Consider the type of fabric you inspect most often. There are systems designed specifically for different types of fabrics, so it's important to choose one that's well-suited to the fabrics you work with most frequently.

2. Think about the size of the batches you typically inspect. Some systems are better equipped to handle large batches than others. Make sure to choose a system that can accommodate the batch sizes you typically work with.

3. Determine what level of automation you need. There are fully automated systems and semi-automated systems available. Fully automated systems are typically more expensive, but they can also offer a higher degree of accuracy and efficiency. Semi-automated systems may be a more affordable option, but they require more manual input from users.

4. Consider your budget. Automated fabric inspection systems can vary widely in price, so it's important to consider how much you're willing to spend on such a system. Keep in mind that the most expensive option isn't necessarily the best option for your needs – sometimes, mid-range or even budget options can provide excellent value for money.

Common Challenges with Automated Fabric Inspection Machines

When it comes to automated fabric inspection machines, there are a few common challenges that users face. One challenge is keeping the machine clean. With all of the lint and dust that is created during the inspection process, it’s important to keep the machine clean to prevent any build-up or clogging. Another challenge is making sure that the fabric is correctly positioned on the machine. If the fabric is not positioned correctly, it can cause creases or wrinkles in the fabric, which can impact the quality of the inspection. Finally, users need to be careful of operator error when using an automated machine. If operators are not familiar with how to use the machine, they can make mistakes that can damage the fabric or cause issues with the quality of the inspection.

Conclusion

Automation in the fabric inspection machine is revolutionizing how companies inspect their fabrics, providing improved accuracy and efficiency. Automated inspections make it possible to quickly identify defects, reducing waiting times and improving quality control throughout the process. It can also save time by digitally cataloging inspected products for future reference. Investing in an automated fabric inspection machine is a great way for businesses to safeguard their investments by ensuring that quality standards are continuously met.

SUNTECH also provides fabric roll cutting machine, fabric measuring and cutting machine, fabric cutting machine, fabric releasing machine, beam truck, automatic packing machine, fabric measure and cutting machine, auto packing machine, fabric cutting machine, fabric cutting machine for garment. SUNTECH never stop innovation and welcome your any visit, check on our website! https://suntech-machine.com/

https://www.suntech-machine.com/product/tubular-fabric-inspection-machine-25.html