Weaving production has a complete set of processes in the textile industry, and warping is an essential warp preparation process. And the most important carrier in the warping process is the warp beam or the fabric strip cutting machine.

Warping is the process of combining yarns from different cones together to form a sheet. The important point in the warping is to preserve the yarn elongation and maintain it at uniform level.

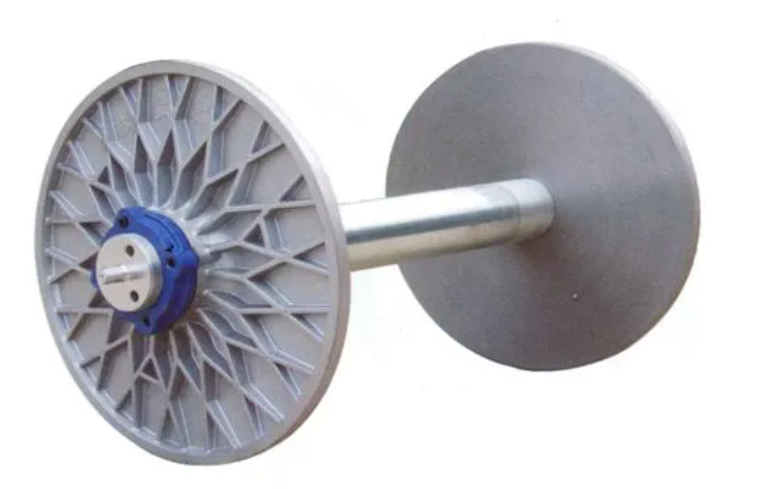

Warp beam

The warping processing methods are mainly divided into: 1. Batch warping, the total number of warp yarns required for full-width fabrics is divided into several batches, and the warp yarns of each batch are wound on a warp beam by a batch warping machine, and wound into several batches. The process of only warp beam, and then synthesizing beam through sizing machine or beam doubling machine. It is mainly used for single-color or primary-color yarns and simple warp arrangements that require sizing, such as cotton weaving and linen weaving. It has high production efficiency and is suitable for mass production. ②Slit warping, according to the arrangement cycle of colored yarns and the capacity of the creel, divide the total number of warps required by the fabric into several strips with the same number as possible, and arrange them one by one according to the width, length and arrangement required by the process. The process of winding the strips in parallel on the warping drum, and then winding all the strips together to the weaving shaft. It can be directly made into a weaving shaft, which is widely used in wool weaving, yarn-dyed weaving, silk weaving and other industries. ③Segmental warping, the process of first winding a part of the warp yarns required for the full width of the fabric on the narrow-width small warp beam, and then unwinding thousands of narrow-width small warp beams at the same time into a wide-width warp beam. In order to weave fabrics arranged in a symmetrical pattern, the turning of each narrow small warp beam can be arranged at intervals of clockwise and counterclockwise. If a number of narrow and small warp beams are threaded on the shaft tube in sequence, a weaving shaft for warp knitting machines and knitting machines can be formed. It is mainly used for warp processing of symmetrical patterns and repeated patterns, which can improve production efficiency. ④Ball warping, divide the total number of warps required for the full-width fabric into several yarn bundles according to the capacity of the creel, and wind each yarn bundle into a spherical yarn group, which is dyed by the rope dyeing machine in the rear, and then finished by the whole yarn. The process of being rolled into a warp beam by a machine. After the beam is sizing, the beam is synthesized. The dyed ball warp can be directly warped, and it is mostly used for the preparation of the warp before weaving of denim.

The quality of the warp beam in the warping process will directly affect the production efficiency of the subsequent process and the quality of the final fabric. Therefore, the technical requirements for the warping process are: 1. The warp yarns of the whole piece are evenly arranged, the difference in tension is small, and the winding density of the warp beam is on the left. The center and right, inside and outside are uniform, and the unwinding is smooth. ② The warping tension is appropriate to maintain the strength, elongation and elasticity of the warp. ③ The number of warping roots, warping length and yarn arrangement are correct. ④Reduce the broken ends during warping, and avoid the broken ends to be involved.

SUNTECH is a professional worldwide enterprise with decades of experience and research. For more information about the weaving process, please visit SUNTECH website learn more about this.