High-quality fabrics have a better drape, a smoother texture, and a more vibrant color than lower quality fabrics, which affects the way the garment looks and moves on the body, so many textile manufacturers value the quality of the fabric. And the visual inspection defects detection is widely used to help improve the quality of the fabric.

The Importance of High Quality Fabric in the Textile Industry

The quality of the fabric used in clothing and other textiles is an important factor that affects the durability, appearance, and comfort of the garment. There are several reasons why the quality of the fabric matters:

l Durability and longevity

High-quality fabrics are made with strong fibers that are woven together tightly to create a sturdy material that can withstand wear and tear, so clothing made with high-quality fabric will last longer and maintain its appearance over time.

l Appearance

High-quality fabrics tend to have a smoother, more uniform texture, which can make clothing look more elegant and refined. In addition to texture, the color of the fabric can also be affected by quality. High-quality fabrics tend to have deeper, more vibrant colors that are less likely to fade over time.

l Comfort

High-quality fabrics tend to be softer and more breathable than low-quality fabrics, which can make clothing feel more comfortable against the skin. This is especially important for clothing that is worn close to the body, such as underwear or active wear.

l Sustainability

Another reason why the quality of the fabric matters is sustainability. High-quality fabrics are often made with natural fibers that are grown without harmful chemicals or pesticides, which can have a positive impact on the environment.

l Value for money

While high-quality fabrics may be more expensive than low-quality fabrics, they often offer better value in the long run due to their durability and longevity. Clothing made with high-quality fabric may last for years or even decades, while clothing made with low-quality fabric may need to be replaced after just a few wears.

Advantages of the Visual Inspection Defects Detection for Fabric Inspection Machine

Visual inspection defects detection for fabric inspection machines offers a range of advantages over traditional manual inspection methods. Here are some of the most significant benefits:

l Improved accuracy

The system uses advanced algorithms and image processing techniques to identify and analyze fabric defects with a high level of precision, eliminating the risk of human error that can occur with manual inspection, such as missed defects or inaccurate defect classification.

l Increased speed

The system can scan and analyze fabrics at rates far exceeding what can be accomplished through manual inspection, increased speed allows manufacturers to improve their production rates and reduce costs.

l Consistency

visual inspection defects detection provide consistent results, regardless of the operator or environmental conditions.

l Reduction in labor costs

The system can operate continuously without breaks, reducing the need for multiple operators to perform the manual inspection.

l Improved defect classification

visual inspection defects detection can accurately classify defects based on their type and severity, allowing manufacturers to identify and address the root cause of defects, improving their overall quality control processes.

l Increased product quality

By identifying and addressing defects early in the production process, visual inspection defects detection can improve the overall quality of finished products.

l Improved traceability

visual inspection defects detection can record and store inspection data, providing manufacturers with a detailed record of each fabric inspection.

l Flexibility

visual inspection defects detection can be customized to meet the specific needs of different fabrics and production processes.

l Reduced waste

By identifying defects early in the production process, visual inspection defects detection can help reduce fabric waste.

Conclusion

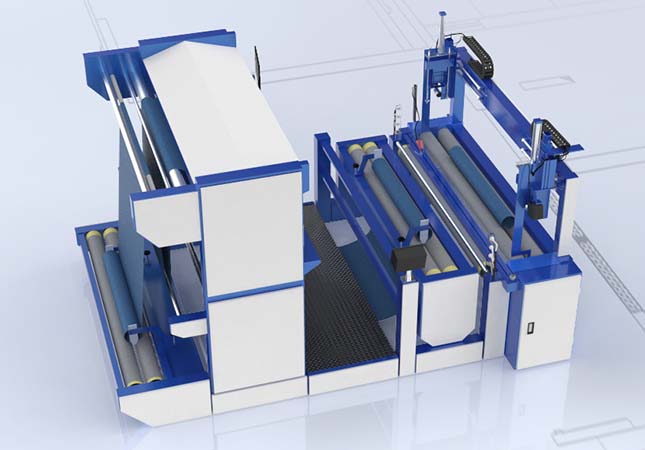

In summary, visual inspection defects detection for fabric inspection machines offers a range of benefits over traditional manual inspection methods. SUNTECH's ST-ACI-I automatic camera inspection system ( for Fabric Inspection Machine ) is known for its outstanding outcomes, qualified and praised by customers in China and abroad. Other than that, SUNTECH also offers numerous types of textile machinery: visual inspection defects, fabric measure and cutting machine, fabric swatch cutter, beam truck, trolley lift system, fabric roll cutting machine, transporte y almacenamiento de textiles,manejo y almacenamiento de materiales, tipos de equipo para el manejo y almacenamiento de materiales etc.