The textile industry has been an integral part of human life since the dawn of the industrial revolution. Today, it continues to wield substantial influence over our global economy. Yet, with the relentless march of technology, the machines driving textile production are undergoing profound transformations, opening the door to a new era of innovation and change.

A Glimpse into the Textile Machinery Industry

In recent times, the textile machinery sector has witnessed a whirlwind of evolution. It has become a hotbed of fresh technologies and groundbreaking innovations, igniting fierce competition in a global marketplace and stoking the surging demand for textile machinery. Let's delve into some of the latest advancements and trends shaping this vibrant industry:

- 3D Knitting: Emerging technology in the textile realm, 3D knitting has taken giant leaps forward. It empowers the creation of intricate and elaborate designs, surpassing the capabilities of traditional knitting methods. This innovation offers unparalleled precision and unlocks new horizons for creative expression.

- Laser Cutting: Often partnered with 3D knitting, laser cutting raises the bar in design complexity. Its remarkable precision allows for the production of intricate patterns and shapes, pushing the boundaries of textile craftsmanship to new heights.

- UV Printing: UV printing is a cutting-edge technique that leverages ultraviolet light to cure inks. The outcome is a stunning palette of vivid and vibrant colors. This technology is particularly suitable for fabrics exposed to sunlight or challenging lighting conditions, ensuring long-lasting visual impact.

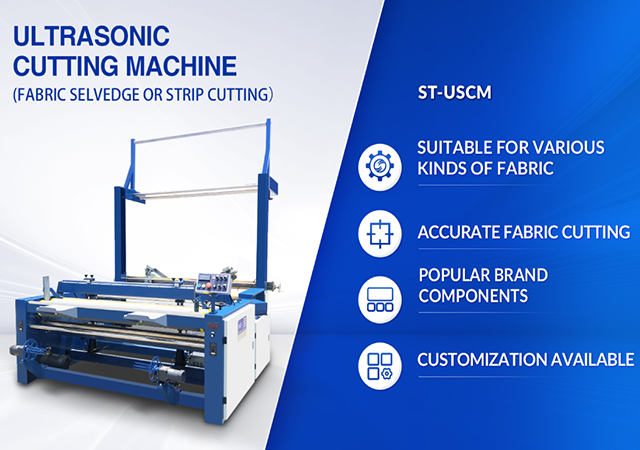

The SUNTECH Fabric Cutting Machine (ST-USCM)

The SUNTECH ultrasonic fabric cutting machine (ST-USCM) is tailor-made for polyester fabric edges, delivering optimal performance. It excels in cutting strips without harming the fabric's edge. Key features of this ultrasonic fabric cutting machine include:

1. Suitability for Polyester and Blended Fabrics: The machine is adept at cutting both polyester and blended fabrics, ensuring efficient and precise results.

2. Fabric Edge Preservation: Utilizing ultrasonic cutting, SUNTECH ensures that the fabric's edge remains intact without any undesired damage.

3. Versatile Cutting Options: This machine offers a range of cutting types, allowing flexibility to meet diverse cutting requirements and preferences.

4. Customization: SUNTECH Textile Machinery provides customization options, tailoring the machine to specific demands and preferences.

These innovations are emblematic of the transformative strides made in the textile machinery industry. With a plethora of new technologies at hand, the textile sector's potential for creativity and innovation knows no bounds.

Investing in the Textile Machinery Industry: A Wise Choice

The recent innovations in the textile machinery industry have ushered in a new era of efficiency and productivity. Here are some compelling benefits of investing in this dynamic sector:

- Increased Efficiency: The introduction of new machines and technologies has heightened efficiency, driving down costs and boosting profitability.

- Improved Quality: State-of-the-art machines and technologies enable better quality control, resulting in superior product quality.

- Higher Productivity: Modern machines handle larger workloads in shorter timeframes, leading to increased productivity.

- Greater Flexibility: The latest machines offer enhanced flexibility in fabric handling and other operations, leading to faster turnaround times and reduced production costs.

- Enhanced Safety: Technological advancements in machine design have brought about improved safety features, safeguarding both workers and products.

In Conclusion

The textile machinery industry has undergone a revolutionary transformation, making production faster and more efficient. Innovations such as computer-controlled machines that adapt to fabric thickness and density changes have expanded the range of products that can be manufactured with reduced waste.

Notably, the advent of 3D printing technology in the textile machinery industry has unlocked the potential for intricate designs and patterns that were once deemed impossible using traditional methods. These 3D-printed textile products often exhibit superior strength and durability while drastically reducing production time.

The textile machinery industry is in a perpetual state of evolution, with ongoing introductions of new innovations. To maintain a leading position in this dynamic and ever-changing sector, companies must stay abreast of the latest developments.