The textile industry has contributed greatly to the progress of human society. The textile industry has entered a new era for human society, and the rise of all industrial countries is almost dependent on the development of the textile industry. The textile industry has enabled the people of all industrial countries to get rid of poverty and develop. Contributed to the promotion of society.

Textile is a light industry. From the perspective of political economy, the organic capital ratio of the textile industry is relatively low. Therefore, it is a "labor-intensive" industry with relatively low technical and basic requirements. This is why there are many in the world. In the early stage of national industrialization, most of them took the development of the textile industry as their own industry.

The textile industry is also a very important industry in the national economy. It firstly meets the needs of human beings for dressing, and secondly provides raw materials for other industries. It has a wide range of applications, including household life, health care, transportation, construction and geotechnical, safety protection, Filtration and separation, structural enhancement, etc., such as: geotextile is an important raw material for the manufacture of highway paving, and aerospace materials have developed the aerospace industry.

It can be seen that textiles are widely used and touch all corners of human life. Once the textile industry ceases, people's lives will fall into confusion.(try suntech Rapier loom)

The 2020-2021 epidemic will continue to repeat around the world, resulting in a large number of textile factories shutting down and textile shortages. In order to meet the supply of textiles during the epidemic, companies in areas where the epidemic is not severe must work overtime to produce. However, labor shortages often occur during the epidemic. There are no workers, and labor costs are constantly rising. How can we ensure production without increasing manpower? At this time, high-speed and efficient intelligent equipment has become the savior of textile enterprises and the gospel of human health.

But equipment also has a cost. How to maximize the value of equipment? As the saying goes, good steel is used on the blade, and smart devices are used in key links that consume a lot of manpower in order to achieve the highest cost performance. So, what are the most labor-intensive key links in textiles?

The key link of textile-weaving

The traditional textile process includes love cotton, carding, combing, drawing, roving, spun yarn, winding, twisting, spinning, wrapping, warping, sizing, drawing-in, weaving and other processes. Among them, the weaving process It is the most quintessential and labor-intensive link. It can be said that it is a key process to improve the efficiency and speed of weaving.

Weaving is an important process in textile mills. The task of weaving is to interlace the warp yarns and weft yarns that have been processed by the intended process through the loom according to the fabric specifications and in accordance with the affirmative process design. The output, quality and consumption of the weaving process directly affect the economic benefits of the enterprise, and it is the link that the weaving factory attaches great importance to and has the largest investment cost.

The weaving process is the most quintessence of textiles and the most difficult link to control. It seems simple, but the most labor-intensive, and the highest technical content is the key to improving production efficiency. It can be said that if the weaving process can be fully automated and intelligent Production will greatly improve the overall efficiency of textiles and reduce labor costs.

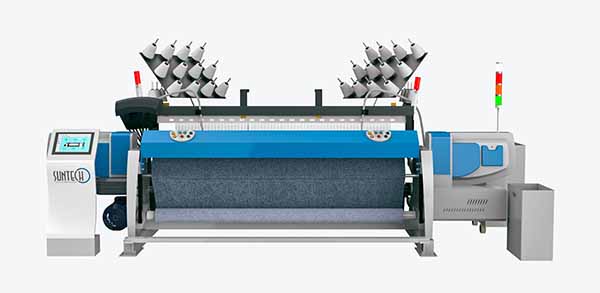

Suntech has developed and produced Ultrafast Start rapier loom with 50 years of design experience and technology accumulation, which is specifically designed for the characteristics of the weaving process, specializing in inefficiency, and completely realizes the transformation from manual weaving to mechanical weaving, and improves the weaving efficiency with intelligent applications, thus greatly Improve the production quality and speed of sanitary products, so that the quality of life is firmly in the hands of human beings.

This Ultrafast Start rapier loom is widely used, suitable for the weaving of various natural fibers (cotton, linen, wool, silk, etc.), polyester, glass fiber, etc., and also suitable for special industrial fibers such as glass fiber, metal fiber, and basalt fiber. Production.

Super high speed, the maximum speed can reach 800 rpm, and the stable speed can reach 550~660 mpm. Using super motor, the instantaneous torque of the motor can reach 300 ONm, so that the speed ratio can be reached immediately after the loom is started. The motor can run for a long time without being affected by heat.

The alloy steel guide rail is used to ensure the stability of the rapier holder and the rapier tape under high-speed operation, and its wear resistance and service life are 5 times that of the traditional aluminum alloy guide rail. The heavy-duty special steel, solid beam and base ensure the high speed and stability of the loom.

(Ultrafast Start rapier loom)

Suntech specifically addresses the problems encountered by customers in production, and summarizes the following textile production suggestions and Suntech smart rapier looms:

1. Improve product quality.

The quality of the fabric mainly includes the physical properties of cotton and the appearance of defects. The physical properties of the fabric, such as the warp and weft strength of the fabric, abrasion fastness, moisture permeability, etc., directly affect the wearability and wearing fastness, and are determined according to the different uses of the fabric. And it must be manipulated throughout the production process to meet the target requirements.

The appearance of fabric defects such as: creases, sloppy, sloppy, jumping, holes, etc., not only affect the appearance of the fabric, but also have a direct impact on the wearing performance and wearing fastness. Strictly implement the work method in the operation process, often analyze the factors that cause defects in daily management, and propose improvement measures to continuously improve the quality of finished products and increase the rate of first-class products.

2. Improve production efficiency

The production efficiency of the loom is one of the evaluation indicators used to measure the production level. During operation, the loom stops due to broken warp, broken weft, mechanical failure, handling of bad cloth, upper shaft, etc., which affects the output of the loom and the quality of cotton cloth. Take effective measures to reduce end breaks, reduce mechanical failures, deal with stoppages in time, shorten the stoppage time, and strive to improve the production efficiency of the loom.

3. The main material consumption of the loom in the weaving process is machine material, spinning yarn and power. The size of consumption and the quality of raw materials, equipment status, technical operation level, production environment and production conditions are related. Reducing material consumption is an important part of improving economic efficiency.

(1) Reduce machine material consumption:

①Strictly control the quality of purchased machine materials to prevent inferior products from entering the factory.

②Strengthen equipment maintenance to ensure that the equipment is always in perfect condition and reduce the wear and tear caused by poor equipment condition.

③Strengthen technical operations to reduce human losses.

(2) Reduce the amount of spinning yarn;

① Correctly grasp the cloth width and weft density on the machine to avoid multi-purpose threads.

②Strengthen technical operation to prevent the occurrence of weaving defects, achieve less and no dismantling of the finished fabric, and reduce the return of silk.

③Keep the equipment as good as possible to spare the large weft.

④Strengthen production management to reduce oil pollution, bad cloth and weft insertion.

(3) Reduce power consumption:

①Turn off the motor in time when stopping.

②Improve cloth machine efficiency and operating rate.

③Control the lighting and use the air conditioner correctly to prevent the waste of auxiliary electricity.

④Adopt energy-saving belt pulley.

Customers who have used Suntech rapier looms are full of praise for this loom, which can be called artificial intelligence in the loom industry. According to statistics, this loom can save 20%-30% labor costs on average and increase 20%-30 % Production efficiency, so that every step of the textile is intelligentized, and the production speed is greatly increased. Welcome to inquire in detail.