The labor cost of the textile industry is soaring, Suntech electric WARP BEAM HIGH LIFT TROLLEY helps reduce costs

From January to October 2020, China’s exports of textiles, including masks, increased by 34.8%. Behind this, the transfer of textile orders, including India, to the country is one of the important factors.

In 2021, the epidemic in India has intensified, and the return of Indian orders has indeed brought a wave of warmth to China's textile industry. Behind this wave of warming, some companies have made a fortune, while others have even worsened the situation.

Many textile company bosses complained that due to lack of workers, the production capacity could not reach full capacity, which affected the delivery of orders. The person in charge of a manufacturer said that the factory's machinery was fully operational, but last month due to worker problems, a factory only maintained 80% of the operation. The main reason was the lack of skilled workers. After the order skyrocketed, the problem of grabbing fabrics disappeared, but the labor shortage problem came again.

Why is there a labor shortage?

The market suddenly broke out at the end of 2020, and subsequently led to a surge in orders for the mainstream autumn and winter down jackets and cotton fabrics with nylon spinning, pongee spinning, and polyester taffeta. For a while, the market also appeared out of stock, queues and other goods. Textile bosses ushered in the best "honeymoon period" of the year. Inventory of marketable products dropped sharply, and prices of individual grey fabrics also rose.

However, because the market has been in a sluggish state in the first three quarters, many textile bosses have had to implement production cuts, holidays, and wage discounts in order to cut expenses, which has led to the loss of workers. There is no time to recruit workers, workers' wage requirements are high, and skilled workers are difficult to recruit, which leads to a labor shortage.

Labor costs have risen sharply

The textile industry is a typical labor-intensive industry. The labor advantage has made China the world's largest textile exporter. However, starting in 2012, as China's demographic dividend has gradually disappeared, labor costs have increased year by year. The survey shows that the wages of textile factory workers in the southeast coastal areas are concentrated in the range of 5,000-10,000 yuan, and the wages of workers in the central and western regions are roughly 3,000-6,000 yuan.

Five years ago, the company's labor costs accounted for only 20%, and now it has reached 60%. In addition, the instability of employees and the additional costs caused by accelerated turnover are also problems facing the company.

The reason why labor costs will rise is due to the increase in living costs brought about by inflation on the one hand, and the decline in the labor force on the other. Even after 00, I don’t want to do it. The survey found that although the employers believe that the overall salary of the textile and apparel industry is not low, the employees are not very satisfied with it.

The textile industry has fallen into a two-sided unthankful situation. The boss feels that labor costs are getting higher and higher, while the workers feel that the price is too high, the work is hard, and the cost of wages in the textile industry is not high.(try suntech WARP BEAM HIGH LIFT TROLLEY)

Pain points of textile industry upgrading and transformation

1. The contradiction between talents and enterprises. Constrained by capital and cost pressures, many small and medium-sized enterprises find it difficult to recruit workers, especially high-level technical talents and experienced masters. At the same time, skilled workers believe that the textile and garment industry is tired and wages are low, and they do not plan to keep working.

2. Rising raw materials. In the past, the labor cost of textile companies was about 30%, and the material cost was 30%. Now the labor cost exceeds 50%, even up to 60%, and the material cost is also 40%, so it is difficult for the current profit point to reach 5%. Larger quantities can still make money, and price increases are unavoidable.

3. The maturity of the high-end product market in the textile and apparel industry is not high. Generally, it is difficult for small and medium-sized enterprises to produce high-precision automated manufacturing products, and the domestic high-end product market is not yet mature and the market is not large.

Labor costs continue to rise, product prices cannot rise, and profit margins are compressed, causing textile companies to face pressure. At present, the surge in textile orders can be retained for some time, but it is difficult to retain them for a long time. The long-term development of China's textile and apparel industry still has to repeatedly balance between high cost and high quality, and move forward slowly.

How to reduce textile costs?

The main problem at present is that the labor cost is too high and the equipment is not advanced enough. In the textile industry, the pre-production has basically achieved flow operation, and the popularity of mechanization is relatively high. However, the links such as cloth inspection, packaging, finishing, and storage rely on labor. With 50 years of design experience and technology precipitation, Suntech is committed to the research of intelligent textile machinery. The intelligent equipment produced involves textile inspection, packaging, finishing, storage and other links, trying to improve production efficiency through intelligent equipment and greatly reduce labor costs.

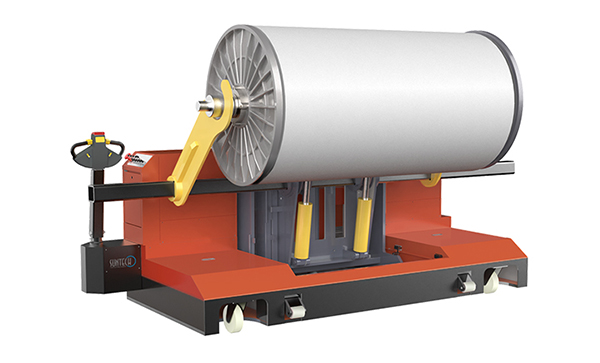

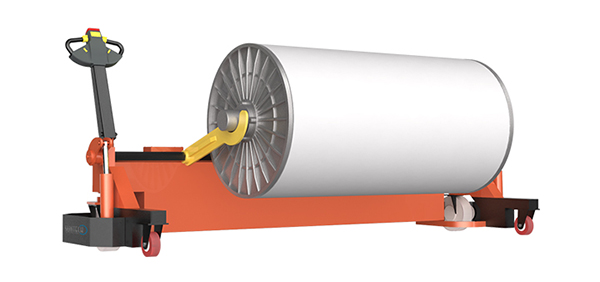

Especially the warehousing and transportation link is time-consuming and labor-intensive. Nowadays, young people are pampering themselves. In the future, there will be fewer and fewer people willing to engage in transportation work. The electric WARP BEAM HIGH LIFT TROLLEY developed and produced by Suntech can just achieve automated transportation. The electric WARP BEAM HIGH LIFT TROLLEY can replace several porters, saving 20-30% of labor costs every year.

Suntech electric WARP BEAM HIGH LIFT TROLLEY through precise mechanical design, so that the mechanical parts can just unload the warp beams and weaving shafts from the loom, seamlessly butt-load them onto the WARP BEAM HIGH LIFT TROLLEY, and then arrive at the axle warehouse after smooth transportation. WARP BEAM HIGH LIFT TROLLEY loads the warp beams and weaving beams into the axle library through mechanical lifting and other processes. WARP BEAM HIGH LIFT TROLLEY is responsive, stable and easy to operate, with large loading capacity and few handling times, adapting to various working environments and making up for manual handling. The defects can reduce the labor intensity of porters in the textile industry, improve work efficiency, greatly reduce labor costs, and improve production effects and product quality.

Suntech electric WARP BEAM HIGH LIFT TROLLEY has the following advantages:

1. Maintenance-free gel battery

2. Electronic power steering

3. The electric side shift function can finely adjust the position of the warp beam

4. Maintenance-free AC motor drive wheels

Suntech, as an old-brand machinery manufacturing company, started with textile and storage machinery and equipment. It has international leading core technology. The electric WARP BEAM HIGH LIFT TROLLEY developed and produced can intelligently transport a large number of cloth rolls, fabrics, weaving beams, and warp beams, and occupy a small area. , Large capacity, fast handling speed, flexible movement, stable transportation, free loading and unloading, strong adaptability to the site, reducing manual operations, improving work efficiency, and using electric and intelligent WARP BEAM HIGH LIFT TROLLEY to help efficient production and ease the storage of textile enterprises For handling pressure, please inquire for details.