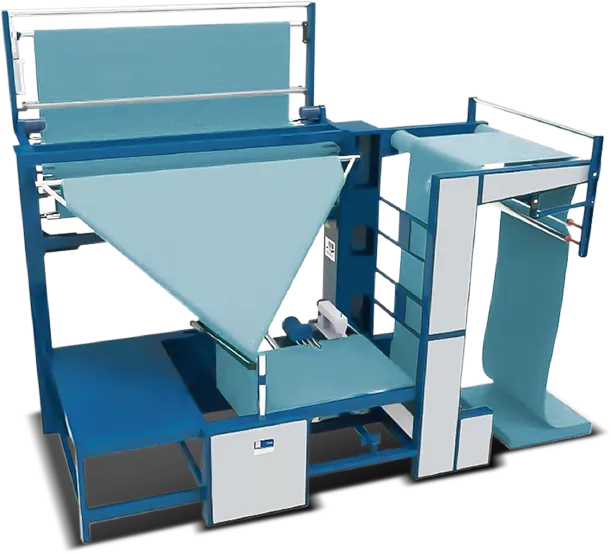

In the fast-paced world of the modern textile industry, innovation and adaptability are paramount. As the demand for specialized equipment continues to surge, SUNTECH Textile Machinery, a leading textile machinery manufacturer, has emerged as a trailblazer, introducing the Automatic Tube-sewing Machine, popularly known as the Double Folding Machine (ST-DFSM). This state-of-the-art solution incorporates an array of advanced features to meet the exacting requirements of contemporary textile production.

Unleashing Versatility in Fabric Applications:

The Double Folding Machine represents a versatile powerhouse, adept at handling a wide spectrum of fabric types. Whether you're dealing with delicate, sensitive materials with curled edges or more standard loose fabric, this machine has been meticulously engineered to manage them all. Say goodbye to compatibility concerns; this device caters to a myriad of fabric applications.

Precise Edge Alignment for Perfection:

At the fabric inlet, the machine deploys a set of pneumatic centering rollers, ensuring that the fabric remains precisely centered. Just before the folding process commences, an additional set of centering rollers fine-tunes the fabric's position. During the intricate folding operation, a pair of edge alignment raster systems comes into play. These high-tech systems diligently scrutinize the edges of the folded fabrics. In the event of any alignment discrepancies, the machine springs into action, automatically correcting the positioning to achieve an astonishing edge-alignment error rate of less than 0.6mm.

Mastery Over Fabric Edge Control:

Managing fabric curled edges has historically been a concern in textile production. SUNTECH's solution integrates a group of scroll rollers at the fabric inlet, efficiently unfurling curled edges. Moreover, a mechanical uncurling device operates just ahead of the edge-alignment raster, ensuring that fabric edges are meticulously detected. Before sewing, an electrical uncurling device and an air blowing mechanism join forces to ensure that fabric edges are fully uncurled, guaranteeing an impeccable sewing outcome.

Single-Thread Sewing for Post-Dyeing Convenience:

The Double Folding Machine adopts single-thread sewing with precision JUKI Brand Sewing Machines, fine-tuned for auto-search of fabric edges. Once the dyeing process reaches completion, operators can effortlessly pull the thread, reverting the tubular fabric to its open width form, streamlining the entire operation. An edge alignment photo sensor constantly tracks the fabric's edge, ensuring the sewing thread remains perfectly straight. Additionally, an automatic break sewing thread detection system is incorporated, automatically halting the machine if a thread break occurs, thus preventing the occurrence of loose stitches.

Accurate Length Counting, Minimized Tension:

One of the machine's standout features is its length counting functionality, boasting an exceptional accuracy rate with an error of less than 0.1m per kilometer. Even in instances where the folding and sewing processes aren't perfectly synchronized, any tension created during the fabric's exit is expertly managed. During sewing, the fabric is meticulously opened, ensuring an exceptional sewing outcome. Any residual tension generated by the tightly pressed fabric is expertly released as the fabric is plaited at the outlet.

Conclusion:

SUNTECH, a distinguished textile machinery manufacturer, stands as a testament to relentless innovation and automation in the textile industry. The Double Fabric Folding Machine (ST-DFSM) represents their unwavering commitment to delivering optimal solutions to modern textile factories. For more information on this groundbreaking machine and a multitude of other innovative solutions, please visit SUNTECH's official website. We eagerly anticipate the opportunity to assist you in elevating your textile production processes and setting new standards for efficiency and quality.