Since the outbreak of the covid-19 in 2020, in addition to epidemic prevention, countries have been stepping up research on the virus, hoping to find the ins and outs of the virus that infects humans, provide a basis for the development of vaccines and drugs, and completely kill the virus. However, virus research is a arduous and long work. Scientists from various countries have studied for more than a year, but have not thoroughly figured out the origin of the virus.

The epidemic first broke out in Wuhan, China, and many scientists speculated that the covid-19 originated from bats.Later, Japan broke the news, before the outbreak in China, the United States had been plagued by influenza, with a higher fatality rate than in previous years, and the flu vaccine did not seem to work. Japanese media speculated that most of the influenza in the United States might be COVID-19. Later, facts proved that many American influenza patients were indeed infected with COVID-19. Many scientists speculate that the COVID-19 originated in the United States and pointed to a certain biochemical base, but they have not yet been determined.

Italy first reported a confirmed case of COVID-19 on January 30, 2020, and the above-mentioned latest study led by the University of Milan, Italy, brought the emergence of “patient zero” in Italy to November 2019. Including this research result, many countries have recently made many new discoveries about the early COVID-19 epidemic, which has triggered new thinking in the academic community on the origin and spread of covid-19.

Researchers have not only found clues to earlier covid-19 infections in humans, research on wastewater also shows that covid-19 may have existed in many countries before the outbreak. The genetic material of covid-19 may enter wastewater from the excrement of infected persons. Epidemiological studies based on wastewater can help to better understand the spread of the virus.

When people have not fully understood covid-19, covid-19 has already mutated. Since the discovery of the mutated virus in the UK, mutated viruses have been discovered in 70 countries.

Recently, Russian scholars have discovered 18 variants of covid-19 in a woman with low immunity. Some variants are the same as the new variants that appeared in the UK, and two variants are consistent with the variant covid-19 carried by Danish mink. .This woman is 47 years old and suffers from lymphoma. In April 2020, the woman was infected with covid-19 during a chemotherapy session. Since then, she has undergone regular nucleic acid tests, and the test results have been positive until September 9.

Konstantin Krutovsky, a professor at the Department of Genomics and Bioinformatics at Siberian Federal University, pointed out that this research work has confirmed for the first time the fact that “covid-19 can cause a large number of mutations in an organism for a long time".

The origin of the virus is unknown, and the current status of the virus is continuously mutating, which makes the development of drugs and vaccines more difficult. At present, it is indeed difficult to take the initiative to attack and completely cure all patients. The only way is to prevent the virus from spreading. Wearing a mask has become the best defense method. For a while, masks have become an urgent epidemic prevention material. China, which was the first to get out of the epidemic, assumed responsibility for mask production.

China's supply of masks

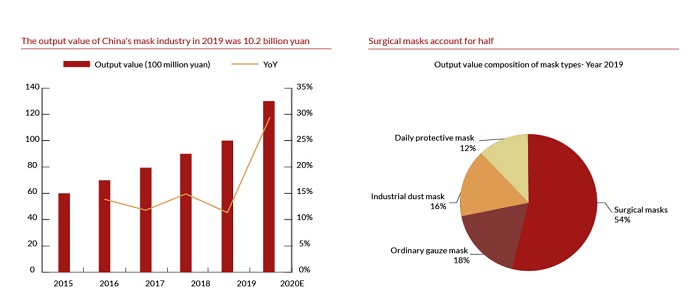

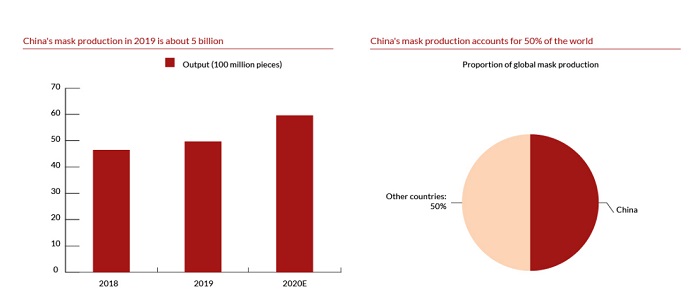

China's mask industry has a scale of tens of billions. In 2018, China's mask production was about 4.54 billion, accounting for 50% of global output, and it has exceeded 5 billion in 2019. The compound annual growth rate from 2015 to 2019 was 13%. In 2019, the output value of the domestic mask industry was 10.24 billion yuan, an increase of 12.6% year-on-year. Among them, the output value of medical masks was 5.5 billion yuan, increase 15.5% year-on-year, accounting for 54% of the market share. China's mask industry started in the 13th century. After years of development, the industry has been relatively mature. The fit, filtration efficiency, comfort and convenience of masks are better. Due to the global epidemic, the growth rate will reach more than 30% in 2020.

However, the current global epidemic continues to worsen, and many people who originally refused to wear masks have also put on masks. The demand for masks is further released. The Harvard University research report points out that the new crown epidemic will continue at least until 2025, and the global daily demand for masks is 20-30. At present, only half of the international demand can be solved, which means that there is a gap of 1 to 1.5 billion daily masks.

At present, China's daily output of masks is about 120 million, and the contradiction between supply and demand is still prominent. In the future, the production of masks will still be at full capacity.

Melt blown cloth becomes the bottleneck of mask production

The production of medical masks involves seven elements: raw materials, equipment, workshops, capital, manpower, access permits, and production cycle. Generally speaking, capital, manpower, and access permits are relatively easy to solve. The production cycle generally requires 7-14 after sterilization. During the static analysis period, the plant requires a 100,000-level purification workshop. The shortage of raw materials and production equipment is the main bottleneck restricting the production of masks in the short term.(try Suntech Melt blown machine)

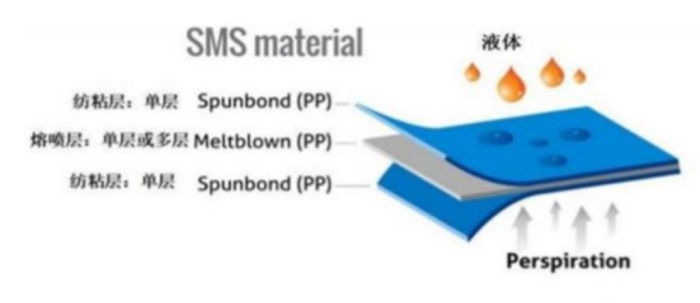

From the classification of masks, commonly used masks can be divided into four categories: medical masks, ordinary gauze masks, industrial dust masks, and household dust masks. Among them, medical masks can be divided into ordinary medical masks, medical protective masks, medical surgical masks, etc. The main body of these masks is composed of spunbond layer-meltblown layer-spunbond layer, the innermost layer is spunbond non-woven fabric; the middle filter layer The use of electret treated polypropylene meltblown non-woven fabric can capture bacteria and viruses and is the core component of the mask; the outermost layer is a non-woven fabric with waterproof treatment, which is mainly used to insulate sprayed droplets.

At present, insufficient supply of melt blown cloth is the main raw material bottleneck. According to statistics from the China Industrial Textile Industry Association, the national output of meltblown non-woven fabrics in 2018 was about 53,400 tons, and each ton of meltblown fabrics can produce 1 million medical surgical masks or more than 500,000 N95 masks. Assuming that 53,400 tons of meltblown cloth are all used to produce medical surgical masks, then 53.4 billion medical surgical masks can be produced, which is converted into a daily output of about 146 million pieces per day. Compared with the current demand for masks in the epidemic environment, the supply is obviously insufficient.

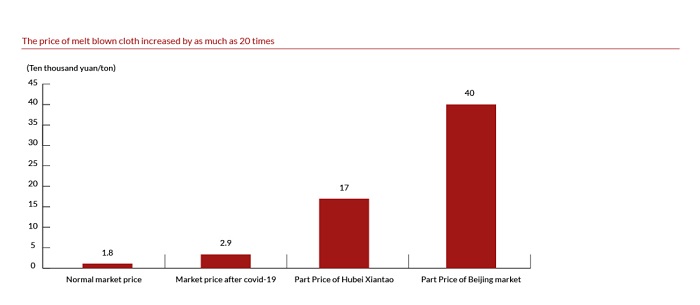

In this context, many domestic companies have expanded their production and switched to producing masks, and their demand for core raw material meltblown cloth has also increased rapidly. Meltblown cloth is due to the high cost of production equipment, long production line construction and long commissioning cycles (imported equipment is about 2000 10,000/set, 3-6 million/set of domestic equipment, production line debugging cycle 3-5 months), short-term increase in supply is difficult to match the increase in demand.

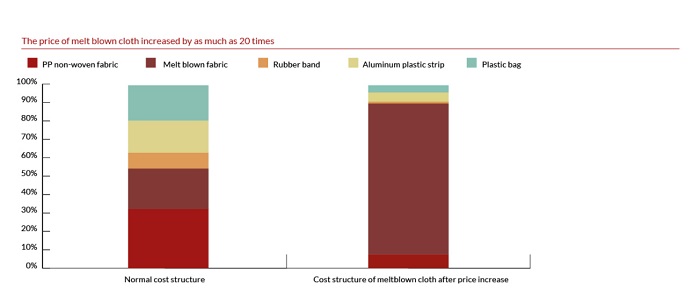

Driven by the fermentation of the epidemic, the market price of melt blown cloth in China has also risen from about 18,000 yuan/ton to 280,000 yuan/ton, and the price of melt blown cloth has risen to more than 400,000 yuan/ton. The market price of core material meltblown non-woven fabrics has soared by more than 60%, and in some regions the increase has been as high as 20 times. The production cost of masks has risen sharply.

Based on the current market price of meltblown non-woven fabrics of about 300,000 yuan/ton, the proportion of meltblown fabrics in the raw material cost of a medical mask has risen from about 20% in the past to about 80%. In addition, the epidemic has caused labor, manufacturing, and logistics. The production cost has also risen, driving the production cost of a medical mask from the normal 0.5 yuan/piece to 1.5 yuan/piece-1.6 yuan/piece.

The fundamental reason for the price increase of melt blown cloth is insufficient productivity of melt blown cloth. With 50 years of technical precipitation and manufacturing experience, Suntech has meticulously developed and designed an intelligent meltblown machine, which has high production efficiency, saves labor, and greatly reduces the production cost of masks. It uses "precision and intelligent manufacturing" to help mask production.