Denim clothing is popular all over the world, conquering the heart of majority of teenagers and many consumers because of its unique style such as strong, wear-resistant and comfortable to wear. The key to the quality of denim is the warp dyeing and sizing, so the quality of the warp beam and weaving beam determines the efficiency of the loom and the quality of the denim.

Do you know how denim fabric came about? How is the quality of denim fabrics controlled? Then let's talk about the production process of denim fabrics today.

Generally, the production of denim fabric is divided into the following steps: BALL WARPING, ROPE DYEING, REBEAMING, SIZING, WEAVING, SINGEING, DESIZING, WEFT STRAIGHTENING, SHRINK-PROOF FINISHING, and FINISHED PRODUCT INSPECTION, ROLLING, PACKAGING & STORAGE.

1. BALL WARPING: Gather a certain number of bobbin yarns (300-450) into bundles of yarns, which are wound on a special roller to form a spherical yarn ball-ball warp. Ball warping is mainly used for the preparation and processing of warp yarns of indigo denim before weaving, which belongs to the rope dyeing technology.

2.ROPE DYEING: The rope dyeing technology of ball warping has the advantages of uniform dyeing (slight color difference) and high sizing output, but its process flow is long, the investment is high, the floor space is large, and most equipment efficiency is low.

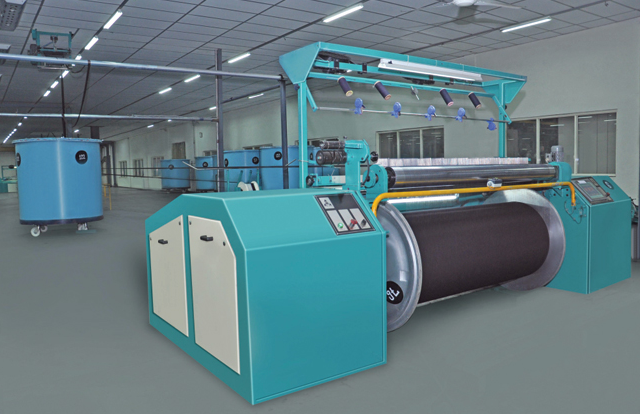

3. REBEAMING: The main purpose is to make the tension, arrangement and rewinding of the yarn sheet or rope bundle uniform, and to rewind a certain number of bobbin yarns evenly and tightly in the specified length with uniform tension. On warp beam or special ball beams, ready for the next dyeing and sizing process.

4. SIZING: The process of applying sizing to warp yarns to improve their weavability. Weavability refers to the ability of warp yarn to withstand repeated friction, stretching, bending, etc. on the loom without causing a lot of fluff or even breakage. The unsized single yarn fibers are not tightly attached to each other, and the surface hairiness is more, so it is difficult to weave. After sizing, a part of the sizing liquid penetrates between the fibers, and the other part adheres to the surface of the warp yarn. The sizing based on the penetration of the sizing between fibers is called permeable sizing, and the sizing based on the sizing sticking to the surface of the warp yarn is called covering sizing.

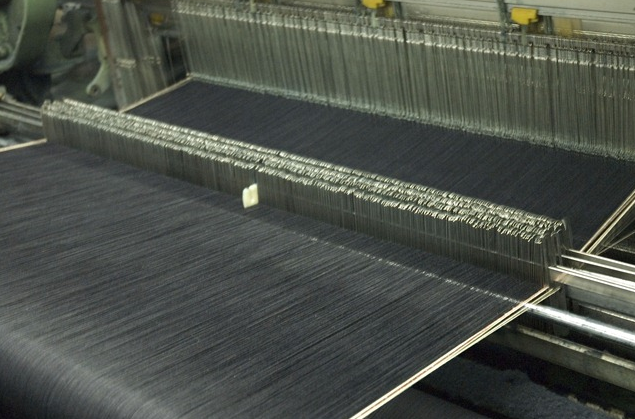

5. WEAVING: Refers to the process of interweaving warp and weft yarns on a loom to form a fabric.

6. SINGEING: The process of making the fabric quickly pass through the flame of the singeing machine or wipe the red-hot metal surface in an open width state to remove the fluff on the surface of the fabric and obtain a smooth surface.

7. DESIZING: The process of removing the size on the fabric, the common methods are hot water desizing method, lye desizing method, enzyme desizing method, oxidant desizing method.

8. WEFT STRAIGHTENING: Twill fabrics have potential weft skew stress inside the fabric due to factors such as yarn twist, tension and fabric structure. Denim fabrics are mostly roving, and the yarn count is generally 36-97tex (16-6s), or even thicker, and the internal stress caused by yarn twisting changes greatly; , the warp and weft are acted in opposite directions, creating a potential weft biasing force. If the fabric is made into clothing without weft straightening treatment, it will inevitably deform. Therefore, it is necessary to bias the fabric in advance to eliminate the internal stress in the weft direction, so that the fabric can obtain a stable weft deviation before the garment, so as to ensure the beauty and performance of the garment.

9. SHRINK-PROOF FINISHING: Refers to the finishing of clothing, etc. to prevent shrinkage. Among them, the mechanical method is an effective method to solve the warp shrinkage, that is, to make the potential shrinkage originally existing in the fabric, let it shrink in advance before it becomes the finished product. Special equipment can be used to complete mechanical shrinkage prevention. In addition, there is a chemical shrinkage prevention method, which is to try to reduce the hydrophilicity of the fiber, so that it cannot swell greatly in water, so that the fabric will not produce serious shrinkage.

As we know the quality of the warp beam and weaving beam is very important for the production of denim fabric, so if you have any requirement on the warp beam or weaving beam, feel free to contact SUNTECH. SUNTECH can provide high quality beam for you!