SUNTECH’s fabric roll wrapping machine can linked Inspection Machine for Online Inspection and Packing(Optional). Ideally,1 set packing system supports max. 10 sets fabric inspection machines at the same time. And compared with European supplier, our fabric inspection machine price and Fabric roll wrapping machine price are more competitive.

The inspection and packaging of fabrics plays an important role in the textile industry. Whether there are defects in the fabric is an important point in the quality inspection of the fabric before it leaves the factory. After the fabric has passed the quality inspection, how to pack and pack the fabric is the focus of textile mills to improve their production efficiency.

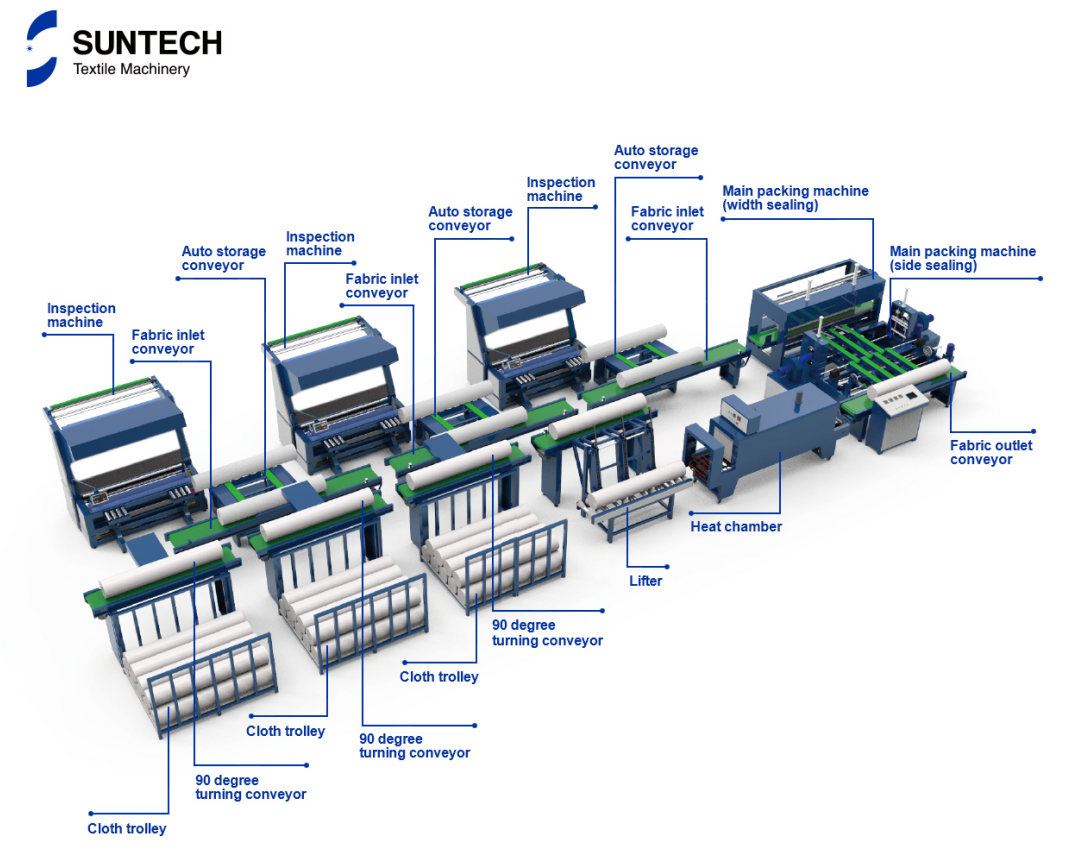

Therefore, in order to make the fabric inspection and packaging process smarter and easier, the SUNTECH fabric inspection and packaging line solution came into being.

In traditional weaving factories, after the fabric is inspected, it needs to be manually moved to the packaging machine and then packaged. Suntech's inspection and packaging line can save labor better, and push the inspected and rolled fabric into After the cloth conveyor belt, the automatic packaging is completed under the control of PLC, and finally enters the cloth trolley.

Work Process

And there are three types of packaging lines are optional:

1. Non-vacuum packaging: cloth feeding conveyor belt - packaging host - cloth storage table

2. Vacuum packaging: cloth feeding conveyor belt - packaging host - cloth feeding conveyor belt - oven - 90° roller conveyor belt - cloth storage table

3. Hot air blowing + slapping: cloth feeding conveyor belt -- packaging host -- hot air blowing device -- slapping device

When the Auto storage conveyor is needed?

Auto storage conveyor is used to store several fabrics rolls, which are waiting to e packed.

If the speed of the Packing Machine is able to catch up with the speed of the Fabric Rolling Machine, it’s no need to install the auto storage conveyor.

If the speed of the Fabric Rolling Machine is faster than the speed of packing machine, the auto storage conveyor is necessary to install after the Fabric Rolling Machine to temporarily store the produced roll

How can the machine pack fabric roll in order?

When there is no Auto Storage Conveyor

The whole process is controlled by PLC .

1) Fabric Roll Input: the fabric roll is transferred to the Main Packing Unit conveyor by Inlet conveyor. The sensor at the entry detects the fabric roll width and diameter and prepare for the following width sealing and side sealing.

2) Width sealing: fabric roll will be pushed to width sealing working position, when fabric roll is in width sealing, main packing unit conveyor will be empty, at this time inlet conveyor will transfer next fabric roll to main packing unit conveyor.

3) Side sealing: After width sealing, the fabric roll is transferred to the side sealing working position. At this time, the width sealing working position is empty and next fabric roll in main packing unit conveyor will be pushed to width sealing working position for width sealing.

4) Fabric Roll Output

When there is Auto Storage Conveyor

1) Fabric roll is temporarily store on the Auto Storage Conveyor

2) When the inlet conveyor which is most near to the Auto Storage Conveyor is empty, the Auto Storage Conveyor will move and send the fabric roll onto that Inlet Conveyor

3) Same step as above 1),2),3),4)

SUNTECH's cloth inspection and packaging line can intelligently help customers to carry out cloth inspection and packaging, which can greatly improve work efficiency. And SUNTECH is a professional worldwide enterprise with decades of experience and research. We are committed to providing customers with excellent products and customized service. Our experienced experts will offer customers timely and effective integrated services in pre-sales consultation, sales, maintenance, and comprehensive after-sales support, giving customers the ultimate and comprehensive service experience.