Non-woven fabrics are made of chemical fibers and plant fibers on wet or dry paper machines, with water or air as the suspending medium. Although it is cloth and not woven. It is a new generation of environmentally friendly materials, with the advantages of good strength, breathability, waterproof, environmental protection, flexibility, non-toxic and tasteless, and cheap price. Rich colors and so on. In this issue of news, let's take a look at the production process of non-woven fabrics.

1. The non-woven fabric is made of polyester and polypropylene, which is carded, combed, pre-needled and main-needled. A mesh interlayer is added in the middle, and then double-pass nucleation, air-laid acupuncture, and compounded into cloth. The filter cloth after filtration has a three-dimensional structure and is heat set.

2. After singeing, the surface of the non-woven fabric is treated with chemical oil to make the filter cloth smooth and evenly distributed. From the surface, the product has good density, smooth both sides and good air permeability. Practice has proved that high-intensity pressure can be used, and the filtration precision can reach 4 microns. Two kinds of raw materials, polypropylene and polyester, can be provided according to user needs.

3. Practice has proved that the performance of non-woven fabrics in plate and frame filter press is better. Coal preparation plant slime treatment and steel plant wastewater treatment. Brewery and dyeing plant wastewater treatment. If other specifications of filter cloth are used, the filter cake will be pressed dry and not easy to fall off. After using its filter cloth, when the filtration pressure reaches 10kg~12kg, the filter cake will be quite dry, and when the filter is opened, the filter cake will fall off automatically. When users choose non-woven filter cloths, they mainly consider filter cloths of different thickness and quality according to air permeability, filtration accuracy, elongation, etc., and can formulate specifications and varieties.

Non-woven fabrics, also known as non-woven fabrics, needle-punched cotton, etc., are made of polyester fiber and polyester fiber material. They are made by acupuncture process and can be made of different thickness, feel, hardness, etc.

It has the characteristics of moisture-proof, breathable, flexible, light and thin, flame retardant, non-toxic and tasteless, low price, recyclable and so on. It can be used in different industries, such as sound insulation, heat insulation, heating sheets, masks, clothing, medical, filling materials, etc.

If the non-woven fabric is decomposed naturally outdoors, the life span is only 90 days, and it decomposes within 8 years indoors. It is non-toxic and harmless when burning, and will not pollute the environment, so environmental protection comes from this.

The above is the production process of non-woven fabrics. This product has no warp and weft threads, so it is very convenient to cut and sew, and it is light in weight and easy to set. It is very popular among craft lovers. Hope the above content can help you better understand the product.

What are the uses of non-woven fabrics ?

Non-woven fabrics are moisture-proof, breathable, flexible, thin, flame-retardant, non-toxic, tasteless, inexpensive, and recyclable. Can be used in different industries, such as sound insulation, heat insulation, heaters, masks, clothing, medical, filling materials, etc.

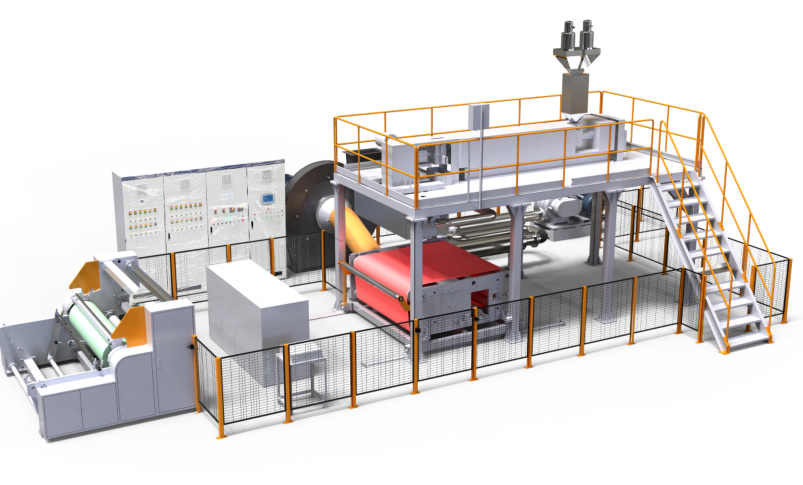

If there have any interest about the non woven machinery, welcome contact with us to get a detail machine catalogue and machine offer for your better understanding.

SUNTECH have over 45 years experience in textile machine manufacture field, so we are highly welcome the fabric manufactures come to ask the questions and we will be very gald to provide the most professional & suitable solution. We also get a lot of non woven fabric slitting machine. If you have interest in it, you can take a look!

welcome contact with us by sales@suntech-machinery.com

Or you can visit our website: https://www.suntech-machine.com/