Non-woven fabrics are moisture-proof, breathable, flexible, thin, flame-retardant, non-toxic, tasteless, inexpensive, and recyclable. Can be used in different industries, such as sound insulation, heat insulation, heaters, masks, clothing, medical, filling materials, etc.

1. What’s the difference of Process principle?

①. Spunbond: After the polymer is extruded and stretched to form continuous filaments, the filaments are laid into a web, and the web is then self-bonded and heated. Bonding, chemical bonding or mechanical reinforcement methods to turn webs into nonwovens

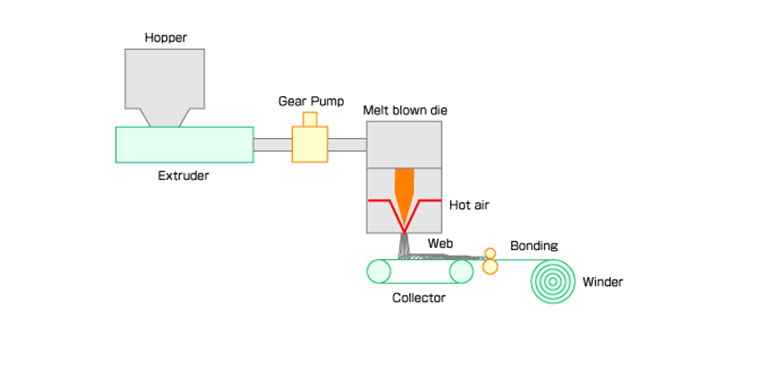

②. Meltblown: The melt-blown non-woven process is to use high-speed hot air to draw the thin stream of polymer melt extruded from the die spinneret, thereby forming ultra-fine fibers and condensing on the condensing screen curtain or drum, and relying on self-adhesion. finished non-woven fabric

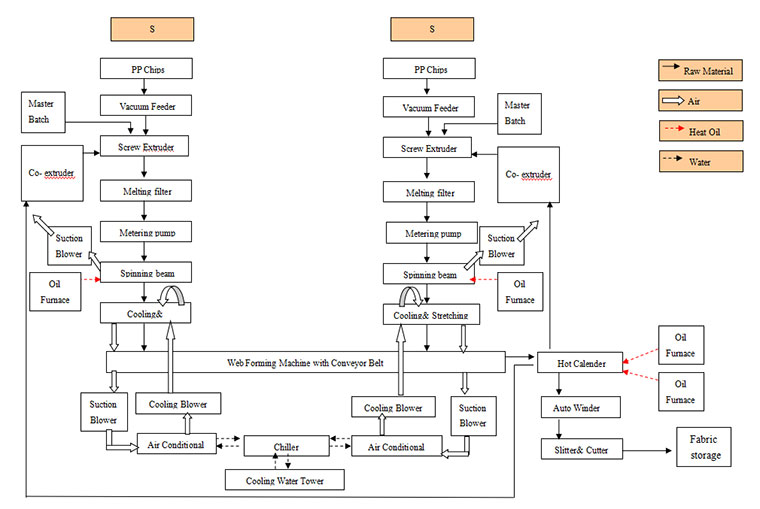

2. What’s the difference of working flow?

①. Spunbond nonwoven machine: Polymer (polypropylene PP spunbond) - large screw high temperature melt extrusion - filter - metering Pump (quantitative conveying)—Spinning (up and down stretching and suction at spinning inlet)—Cooling—Air traction—Net curtain forming—Up and down pressing rollers (pre-reinforcement)—Hot rolling in rolling mill (reinforcement)— - Winding - Reverse distribution and cutting - Weighing and packaging - Finished product storage

②. Meltblown nonwoven machine: Polymer preparation -- melt extrusion -- metering pump -- melt die assembly -- melt trickle drawing -- cooling and receiver

3. What the difference between Fibers?

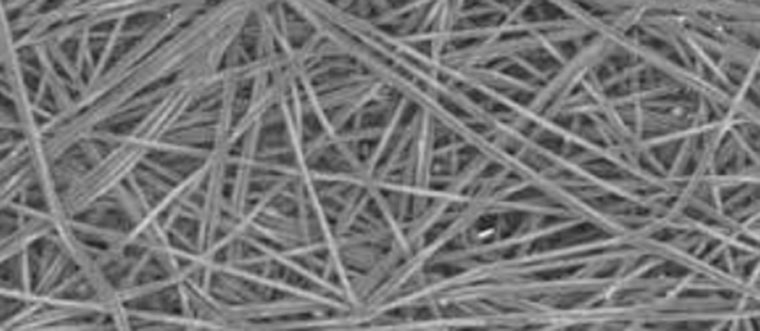

A. Fiber length ------ spunbond is filament, meltblown is short fiber

B. Fiber strength------spunbond fiber strength>meltblown fiber strength

C. Fiber fineness ------ meltblown fibers are thinner than spunbond fibers

4. What’s the difference between Product performance?

The breaking strength and elongation of spunbond fabrics are much larger than those of meltblown fabrics, and the cost is lower. However, the hand feel and the uniformity of the fiber web are poor.

Meltblown cloth is fluffy and soft, with high filtration efficiency, low resistance and good barrier performance. But the strength is low and the wear resistance is poor.

4. What’s the difference in application

①. For Spunbond:

A. medical supplies: Surgical gowns, handkerchiefs, caps, shoe covers, ambulance suits, nursing suits, surgical curtains, etc.

B. hygiene products: Sanitary napkins, diapers, adult incontinence products, adult pads, etc.

C. Clothing: Clothing (sauna suit), lining, pockets, suit cover, clothing interlining.

D. Household items:Simple wardrobe, curtain, bathroom curtain, indoor flower decoration, wipe cloth, upholstery cloth, etc.

E. Holiday necessities: Disposable underwear, pants, travel caps, camping tents, floor coverings, maps, disposable slippers, blinds, pillowcases, gift bags, sweat belts, storage bags, etc.

F. Agriculture: Vegetable greenhouse curtain, seedling raising cloth, livestock shed covering cloth, fruit bag cover, gardening cloth, soil and water conservation cloth, etc.

G. Building waterproofing: Asphalt linoleum base cloth, roof waterproofing, indoor wall covering, decorative materials, etc.

H. Car cloth: Roof, hood lining, traveling compartment lining, seat cover, door panel lining, dust cover, sound insulation, heat insulation material,etc.

I. Packaging: luggage linings, furniture linings, insect repellent packaging bags, deodorant packaging bags, shopping bags, rice bags, flour bags, fertilizer bags, etc.

②. For Meltblown

A. Medical protective equipment

B. Materials for Air Filtration

C. Materials for Liquid Filtration

D. Insulation Materials

E. Oil absorbing material

F. Wipe and Industrial Materials

Meltblown cloth is an excellent sound insulation and buffer material, which is widely used in construction and automobile fields.

If you want to know more information about spunbond non woven machine and Meltblown non woven machine,please visit: https://www.suntech-health.com/