In recent years, non woven fabrics have become an extremely significant part of the textile industry. Defined by ISO standard 9092 and CEN EN 29092, a non woven fabric “is a sheet of fibres, continuous filaments, or chopped yarns of any nature or origin, that have been formed into a web by any means, and bonded together by any means, with the exception of weaving or knitting.”

Non woven fabrics do not rely on interlacing of yarns for internal cohesion. Essentially, they do not have an organized geometry. They are actually the result of the connection between one fiber and another. This provides non woven fabrics with new and better properties, such as absorption, filtration, etc., thus opening them up to other applications.

Applications of Non-woven Fabric

Absorbent hygiene products

Modern disposable absorbent hygiene products make an important contribution to the quality of life and skin health of millions of people. Users of baby diapers, feminine hygiene products and adult incontinence products all benefit from the softness, smoothness, leak resistance, strength and protection provided by non woven fabrics.

Non woven fabrics used in baby diapers, feminine hygiene and incontinence products are listed as followings, top layer or cover, leg sets, core package, backplane, stretch ears, landing zone, dust layer, fastening system, etc.

Agriculture and horticulture

The productivity of crops, gardens and greenhouses can be effectively optimized by using non woven fabrics. Their strong protection means less need for pesticides and much less manual work. The use of non woven crop covers on the land not only increases yields but also improves the quality of crops. Light and flexible sheets are laid over the seed beds, creating a microclimate that controls heat and humidity. Plants grow faster and they are protected from harsh weather conditions and pests. In capillary mat applications, non woven fabrics facilitates in soilless cultivation methods to promote the healthy growth of greenhouse flowers and vegetables.

Some examples of where non woven fabrics are used

1. Crop covers

2. Seed blankets

3. Landscape fabric

4. Biodegradable plant pots

5. Greenhouse shading

6. Root control bags

Medical and Healthcare

Non woven fabrics are widely used in the medical field and other fields for the protection of biological agents to prevent infection and disease. For today's multi-drug resistant bacterial and viral strains, non wovens can help fight against cross-contamination and the spread of infection in medical or surgical settings. Since they are used only once and incinerated immediately after use, the disposal is simple and less polluting.

Here are some instances of where non woven fabrics are used

1. Sponges, Dressings and Wipes

2. Medical mask

3. Disposable hats, gowns, masks, scrubs and shoe covers

4. pollution control gown

5. test clothes

6. Experimental clothes

7. transdermal delivery

8. Shroud

9. wound care

10. cold/hot pack

11. Dosing

Household

Non woven fabrics are used in a variety of household applications, from cleaning and filtration to adding beauty to the home. High-performance non wovens bring comfortable, functional, hygienic and aesthetic solutions for modern living.

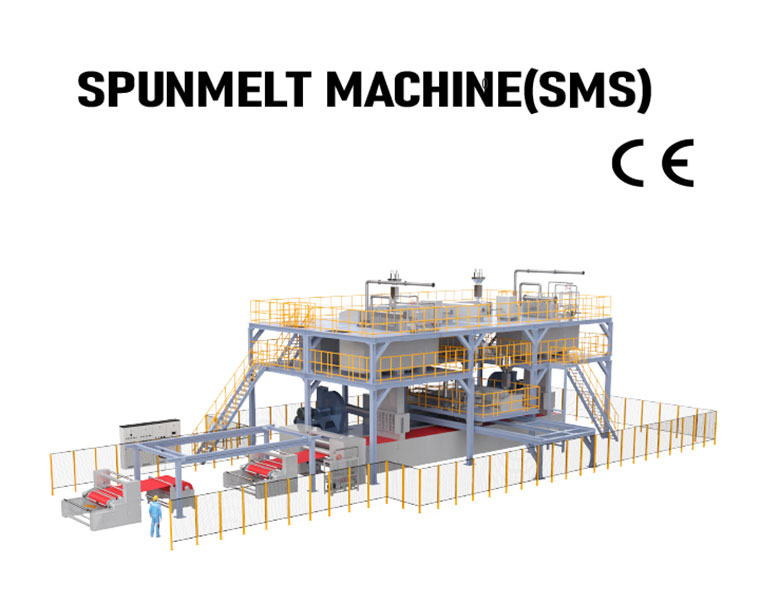

Non woven Fabric slitting machine

In certain industries such as medical protection, there are ultra-strict standards for filterability. For example, medical and surgical masks require materials that meet top-notch bacterial and viral filtration capabilities. Therefore, high-standard and high-quality non woven fabric slitting machines play an important role in the production of non woven related products. With SUNTECH's meltblown production line, you don't need to worry about quality and production stability, which makes you quickly become a reliable and sought-after supplier in the market.

ST-AMB

Features

1. Top-class filterability with water electric treatment option

2. Top quality to meet European Conformity standards

3. Easily enter, easily run

4. Keep stable and safe production with considerable output