Textiles are an integral part of our daily lives, serving as the foundation for clothing, supplies, and various items. The journey from raw material to the final product involves intricate processes, with textile processing methods playing a pivotal role. While the use of textile machines is indispensable, one specific process that significantly influences the overall quality and appearance of textiles is finishing. Let's delve into why finishing is vital for textile processing.

Types of Textile Processing

Weaving, knitting, crocheting, and embroidery are versatile methods employed in textile processing, each contributing unique properties to the fabrics they create. However, beyond these primary methods, finishing, printing, and dyeing are key processes that determine the ultimate characteristics of the textile.

Dyeing

Dyeing, the process of adding color to textiles, is a fundamental step in textile processing. Various methods such as direct dyeing, yarn dyeing, piece dyeing, and tie dyeing are employed to impart color to fabrics. However, it is the finishing process that follows, which plays a crucial role in enhancing the appearance and durability of the dyed fabric.

Finishing

Finishing involves adding protective or decorative treatments to fabric, aiming to improve its overall appearance and durability. Common finishing techniques include coating, laminating, calendaring, and embossing. Whether applied by hand or machine, finishing adds a layer of refinement to the fabric, influencing its final texture and visual appeal.

Printing

Printing, the application of patterns or designs onto fabric, is another integral process in textile processing. Techniques such as screen printing, digital printing, and block printing are employed to create unique designs on the fabric. While printing contributes to the aesthetic aspect, finishing ensures that the printed fabric maintains its vibrant appearance and withstands wear over time.

Texturing

Texturing processes such as napping, flocking, embossing, and ruffle/pleating further enhance the visual and tactile qualities of textiles. These techniques contribute to the creation of varied textures, adding depth and dimension to the finished fabric.

Coating and Lamination

Coating and lamination are methods used to improve the durability and performance of textiles. By applying a thin layer of material to the fabric's surface (coating) or bonding two or more layers of material together (lamination), these processes enhance water resistance, strength, tear resistance, and overall fabric appearance. In some cases, they can even impart fire-retardant properties to textiles.

The Importance of Finishing

In the realm of textile processing, finishing emerges as a critical step in achieving the desired final product. It not only enhances the aesthetic appeal of the fabric but also contributes to its longevity and performance. Whether it's adding a protective layer, creating unique textures, or ensuring vibrant printed designs withstand the test of time, finishing is the key to transforming raw textiles into refined, high-quality products.

Understanding the significance of finishing in textile processing is essential for anyone involved in selecting or working with fabrics. From the initial spinning and dyeing of thread to the intricate processes of weaving or knitting, and finally, to the application of finishing touches, each step influences the end result. Whether for clothing, upholstery, or other projects, choosing textiles with the right processing and finishing ensures a perfect blend of aesthetics and functionality, without compromising on quality or durability.

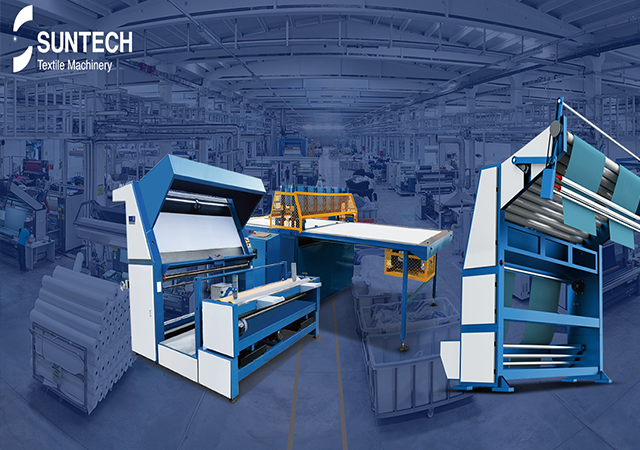

SUNTECH Textile Machinery wholeheartedly embrace the profound impact of digitization and technology across diverse domains, spanning from textiles production and finishing machinery to textiles material handling equipment, ensuring unmatched value and forward-looking solutions for our customers.

Our product lineup includes, but is not limited to, fabric cutting machine, fabric inspection machine and fabric relaxing machine. With our innovative approach and extensive experience, SUNTECH Textile Machinery remains at the forefront of the textile industry.