Non-woven fabrics are also called non-woven fabrics and non-woven fabrics. Is composed of oriented or random fibers. It is called cloth because of its appearance and certain properties. Non-woven fabric has the characteristics of moisture-proof, breathable, flexible, light weight, non-combustible, easy to decompose, non-toxic and non-irritating, rich in color, low price, and recyclable. For example, polypropylene (PP material) pellets are mostly used as raw materials, which are produced by continuous one-step method of high-temperature melting, spinning, laying, and hot-pressing coiling.

The industrial chain of non-woven fabrics is as follows:

Upstream material: viscose fiber, polyester fiber, polypropylene fiber Midstream processing: non-woven fabric manufacturing Downstream applications: medical and health, home care, beauty salons, agriculture, industry, automobiles, leisure, tourism, clothing, office, construction, etc. Among them, the products in the medical and health field mainly include disposable masks, protective clothing, surgical gowns, isolation gowns, laboratory gowns, nurse caps, surgical caps, doctor caps, surgical kits, maternity kits, first aid kits, etc.

Non-woven market analysis

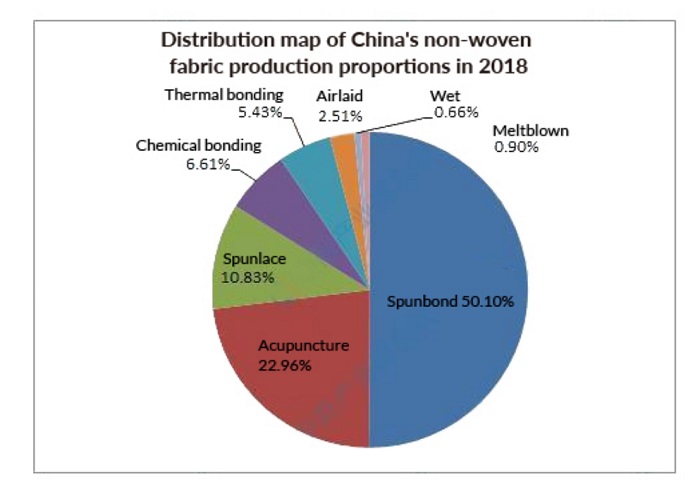

1. Types of non-woven fabrics

China is the world's largest producer and consumer of non-woven fabrics. In recent years, based on the advantages of non-woven fabric production technology and product performance, the non-woven fabric industry has developed rapidly in China. At present, China has become the world's largest non-woven fabric producer and consumer. According to the statistics of the China Industrial Textile Industry Association, the production process of China's non-woven fabric industry is mainly spunbond. In 2018, the output of spunbond non-woven fabric was 2,971,200 tons, accounting for 50.09% of the total non-woven fabric output. Mainly used in sanitary materials and other fields; followed by acupuncture process accounted for 22.96%, spunlace process accounted for 10.83%, chemical bonding process accounted for 6.61%, thermal bonding process accounted for 5.43%, air-laid process accounted for The ratio is 2.51%, the melt blown process accounts for 0.90%, and the wet process accounts for 0.66%.

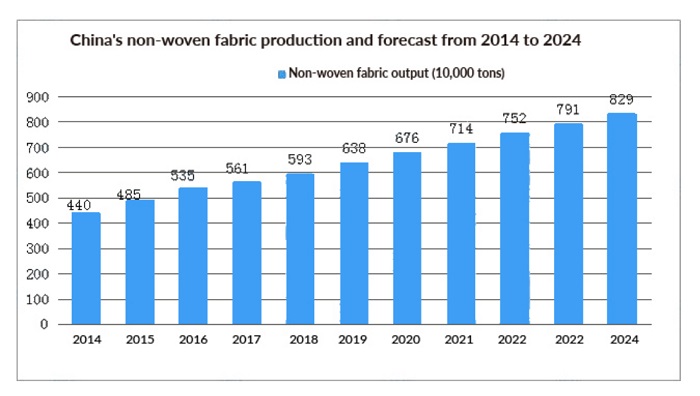

2. Non-woven fabric market scale

From the perspective of non-woven fabric output, China's non-woven fabric has shown an exponential growth in the early stage of industry development. From 1978 to 1997, the annual output of China's non-woven fabric has doubled by nearly 100 times. Since entering the 21st century, China’s non-woven production has maintained a growth trend. After the 2008 financial crisis, China’s non-woven production has continued to increase year by year. In 2018, China’s annual output of various non-woven fabrics reached 5.932 million tons, an increase of 196.31% over 2008. The compound annual growth rate reached 11.47%. In terms of application, the current application of non-woven fabrics is focused on the penetration of high-tech and the use of new materials. It is widely used in construction, automobiles, clothing, sanitary materials, aerospace, environmental protection and other industries, especially in the sanitary materials market. The demand is gradually expanding, and the automotive textiles, footwear and artificial leather markets are also showing a new atmosphere. With its high added value and high efficiency competitive advantages, non-woven fabrics have great potential in the industry. China Commercial Industry Research Institute predicts that by 2024, China's non-woven fabric output is expected to exceed 8 million tons.

3. Layout of non-woven fabric industry base

Currently, China has six non-woven fabric production bases, which are located in Changyuan City, Henan Province, Xiantao City, Hubei Province, Shaoxing City, Zhejiang Province, Zibo City, Shandong Province, Yizheng City, Jiangsu Province, and Nanhai District, Guangdong Province. Among them, Xiantao City, Hubei Province, the hardest hit area of the epidemic, is the non-woven capital of China. It is reported that Xiantao City, Hubei Province has 1011 non-woven fabrics and its products enterprises, of which 103 are above designated size, with more than 100,000 employees. It accounts for 60% of the non-woven product market share in China.

In addition, Nanhai District of Guangdong Province is a demonstration base for non-woven products for medical and health use in China. The demonstration base is located in Jiujiang Town, Nanhai District, with a total planned area of about 3.32 million square meters. The northern part is divided into four areas: material production area, finished product production area, high-end industrial area and logistics warehouse distribution area. The medical and health non-woven fabric demonstration base will be built into an industrial agglomeration base with an annual output value of more than 20 billion yuan. Suntech non-woven products can meet various standards.

(suntech Non-woven fabric)

Melt blown cloth analysis

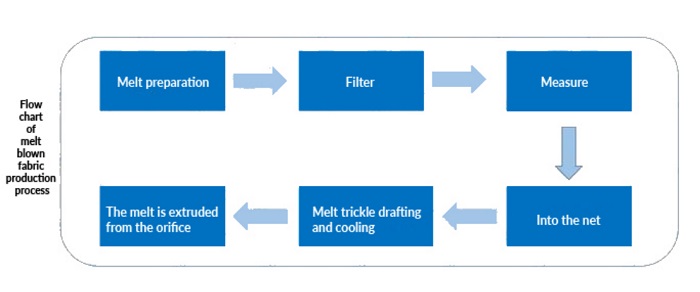

1. Introduction of melt blown cloth

During the covid-19 epidemic, due to the surge in demand for masks and protective equipment, the non-woven fabric industry has developed rapidly. Among them, the most in short supply is melt blown cloth. Because the mask is composed of two layers of spunbonded non-woven fabric and a layer of meltblown fabric in the middle, it is the meltblown fabric that actually plays the role of bacteria isolation. The production technology of meltblown fabric is relatively difficult and requires high equipment. The output is not high. During the epidemic, the demand for melt blown cloth increased sharply, causing the supply to fall short of demand and the price to rise sharply. Suntech's intelligent melt blown machine greatly improves the production efficiency and productivity of melt blown cloth, and solves the problem of melt blown cloth supply.

(Suntech ST-AMB Meltblown machine)

Melt blown cloth is the core material of masks, and it can be used in air, liquid filter materials, isolation materials, absorbent materials, mask materials, thermal insulation materials, oil-absorbing materials and wipe cloths.

Melt blown cloth is mainly made of polypropylene, and the fiber diameter can reach 1 to 5 microns. There are many voids, fluffy structure, and good anti-wrinkle ability. These ultrafine fibers with unique capillary structure increase the number and surface area of fibers per unit area, so that the meltblown cloth has good filterability, shielding, heat insulation and oil absorption.

2. Market scale of melt blown fabric

On March 8, 2020, the State-owned Assets Supervision and Administration Commission of the State Council introduced that in the face of the blowout demand for the core material of masks, the State-owned Assets Supervision and Administration Commission of the State Council has guided and promoted relevant central enterprises to accelerate the construction of production lines, put into production as soon as possible, and expand the supply of melt blown cloth market to help the epidemic Prevention and control provide protection. According to statistics from the China Industrial Textile Industry Association, the annual output of various non-woven fabrics in China reached 5.932 million tons in 2018, an increase of 196.31% over 2008. According to China's meltblown non-woven fabrics accounting for 0.9% of non-woven fabric production, the output of China's meltblown non-woven fabrics in 2018 is about 53,400 tons.

3. Enterprise structure of melt blown fabric

Compared with multinational companies, although some domestic melt blown cloth production enterprises have a certain scale, they have also achieved some gratifying research results in independent research and development and product quality. But in general, the business model is still small and fragmented, with low industry concentration and low level of specialization; companies are scattered in various industries and groups, with backward technology, inefficient equipment, and small production scale, and they have not yet formed a complete System and strong overall competitiveness. At present, China's melt blown cloth companies are mainly located in Anhui, Guangdong and Shandong, and the three provinces' melt blown cloth companies account for more than 70% of the country.

Non-woven upstream analysis

The upstream of non-woven fabric is the raw material for non-woven fabric production, mainly polypropylene. The main raw materials of medical masks are meltblown cloth, non-woven fabrics, polypropylene, nose strips and other raw materials; the main materials of medical protective clothing are polyolefin and PTFE: there are many types of medical protective clothing materials, mainly including polypropylene spunbond fabric, new Polyester fiber and wood pulp composite spunlace cloth, SMS non-woven fabric, polymer coated fabric, breathable film/non-woven fabric composite fabric; the main raw materials of medical protective gloves are nitrile latex, PVC paste resin, plasticizer, Viscosity reducer and various auxiliary materials.

Polypropylene (PP for short) is a semi-crystalline thermoplastic. Polypropylene is a polymer formed by the addition polymerization of propylene. It is a white waxy material with a transparent and light appearance, high impact resistance, and strong mechanical properties. It is widely used and is one of the world's five largest synthetic resins and a very common polymer material. From the downstream side of the industry, polypropylene is widely used in plastic weaving, medical, packaging, automotive and other fields.

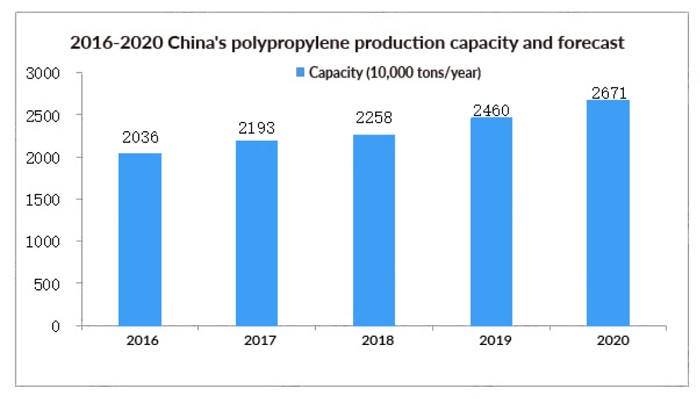

In recent years, China's polypropylene supply capacity has been significantly improved. Data show that in 2016, China's polypropylene production capacity was about 20.36 million tons per year, and in 2019 it has increased to 24.6 million tons. In 2020, China's polypropylene production capacity will exceed 26 million tons, and the industry's production capacity will grow rapidly. From the perspective of raw material supply, thanks to the technological advancement of coal chemical industry and coal-to-olefins, coal-based PP has grown rapidly, and the production capacity of PP using coal-based propylene as raw materials has reached 6.54 million tons. Against the background of unstable and rising crude oil prices, it is expected that among the production capacity put into production in the next few years, the proportion of coal-based routes will still be relatively high, and the proportion of production capacity will continue to expand.

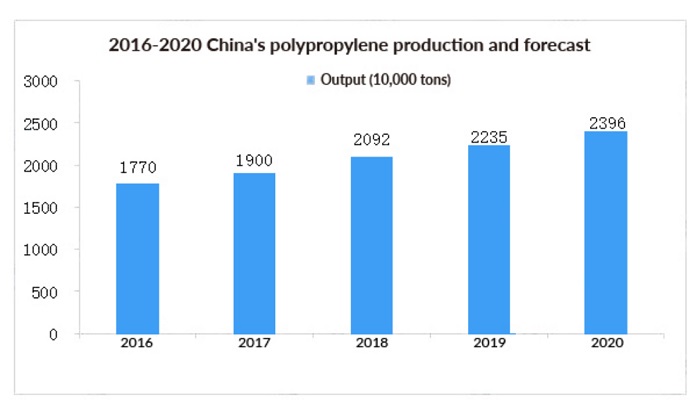

In terms of output, thanks to continuous breakthroughs, mature production technology, and rapid growth in downstream demand, China’s polypropylene production has maintained a steady growth, and the operating rate has also remained high. China’s polypropylene production has increased from 1770 in 2016. Ten thousand tons has increased to 22.35 million tons in 2019. In 2020, China's polypropylene production will reach nearly 24 million tons. Although the newly put into production capacity has brought certain supply pressure, it still cannot meet market demand well.

Non-woven downstream analysis

1. Disposable medical protective equipment

Disposable medical protective equipment refers to medical and sanitary textiles made of chemical fibers including polyester, polyamide, polytetrafluoroethylene (PTFE), polypropylene, carbon fiber and glass fiber. It belongs to disposable non-woven medical protective equipment and medical equipment. Disposable non-woven medical protective products in the industry. Including disposable masks, protective clothing, surgical gowns, isolation gowns, laboratory gowns, nurse caps, surgical caps, doctor caps, surgical kits, maternity kits, first aid kits and other disposable medical consumables series.

Compared with traditional pure cotton woven medical textiles, medical non-woven fabrics have the characteristics of high filtration of bacteria and dust, low surgical infection rate, convenient disinfection and sterilization, and easy compounding with other materials. As disposable disposable products, medical nonwoven products are not only convenient to use, safe and sanitary, but also can effectively prevent bacterial infections and iatrogenic cross-infections.

2. Disposable protective gloves

Disposable protective gloves are used to protect hands from injury. In the medical field, it is mainly used for medical inspection and isolation protection. There are mainly medical examination gloves, sterile medical gloves, and medical X-ray protective gloves. Disposable health protection gloves can be divided into non-woven gloves, nitrile gloves, PVC gloves, latex gloves and PE gloves according to different materials. According to the quality level and use, they can be divided into medical grade and non-medical grade. Medical grade gloves refer to the needs Products that meet the quality certification system or access standards of the target country's medical market are mainly used in medical operations, medical examinations, medical care and other fields.

Disposable protective gloves market size

In China, with the continuous progress of the Chinese economy and the stimulation of special events such as SARS, H1N1, and new crown pneumonia, people's consumption concepts and consumption habits are also constantly changing. The demand for disposable gloves will develop rapidly in the next few years.

According to the data released by the Ministry of Health, if it is only used in the medical industry, according to the data released by the National Bureau of Statistics, China's health technicians reached 10.1 million in 2019. According to the estimate of the proportion of more than 60% of foreign medical industry personnel consuming protective gloves, People consume 6 gloves every day, and the demand in 2019 reached 13.271 billion. Under the impact of the new crown virus pneumonia epidemic, the demand for protective gloves by medical staff and the public has skyrocketed. At the same time, after this epidemic, personal health protection awareness will be raised, and the disposable gloves market has huge potential.

.jpg)

3. Protective clothing

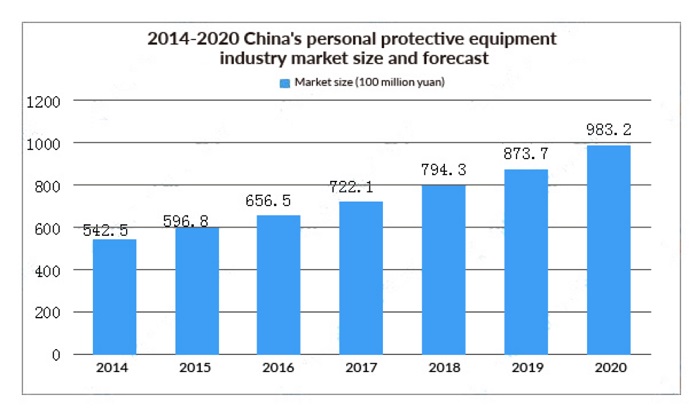

In recent years, the market size of China's personal protective equipment industry has shown a steady growth trend before the spread of the epidemic.

Suntech smart spunmelt non-woven fabric machine can increase the output and production efficiency of SMS non-woven fabrics. The disposable protective products produced with non-woven fabrics can meet various needs.

(suntech ST-SMS melt-blown production line)

From 2014 to 2019, the market size of China's personal protective equipment market (in terms of terminal sales) increased from 54.25 billion yuan to 87.37 billion yuan, with a compound annual growth rate of 10.0%. At the beginning of 2020, China's personal protective equipment industry experienced product out-of-sales and price hikes in the short term of the outbreak, which quickly boosted the market size and growth rate to nearly 100 billion yuan. With the spread of the epidemic, a gap in supply and demand has emerged, and the industry's growth rate has increased significantly. However, after the epidemic has not stabilized, the tight supply and demand situation will ease, and the market size and growth rate will fall back to the previous stable level.

4. Mask

Under the influence of the new crown epidemic, the demand for medical protective products represented by masks, protective clothing and medical disinfectants has surged. During this period, many companies began to produce related products across borders to make up for their insufficient production capacity. Take masks, protective clothing and medical gloves as examples to analyze its market size:

According to data from the National Development and Reform Commission, as of February 29, 2020, including ordinary masks, medical masks, and medical N95 masks, the national daily production capacity of masks reached 110 million, and the daily output reached 116 million, respectively. 5.2 times and 12 times, further alleviating the contradiction between supply and demand of masks. Among them, the daily production capacity of medical N95 masks reached 1.96 million and 1.66 million respectively, effectively solving the protection needs of front-line medical staff.

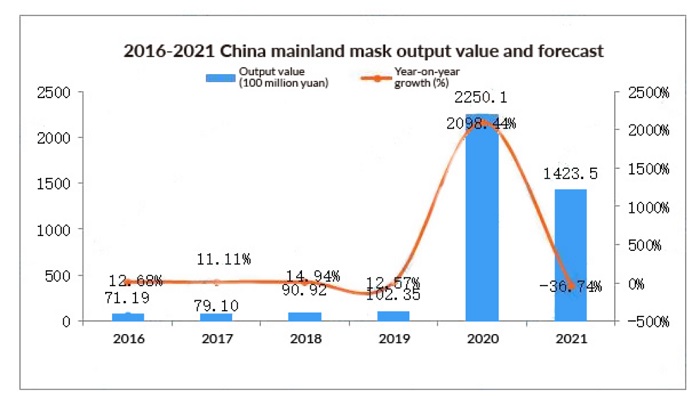

Judging from the data on the output value of masks in mainland China, the output value of the mask industry has maintained a trend of rapid and stable growth, with an average annual growth rate of more than 10%. According to the data in 2019, medical masks accounted for more than half of all types of masks, reaching 54%. The covid-19 epidemic in 2020 has greatly promoted the output value of China's mask industry, and the output value exceeded 225 billion yuan. Among them, The proportion of output value of the medical masks has been greatly increased, with the proportion exceeding 94%.

Application field-medical industry

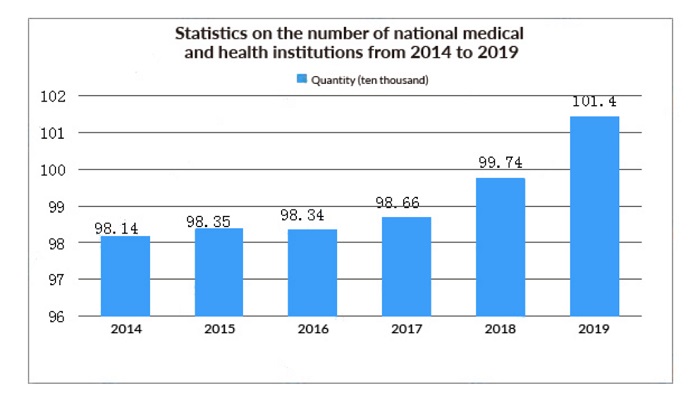

The largest application field of non-woven fabrics can be regarded as the medical industry. Masks, protective clothing, disposable medical gloves, etc. are mainly used by medical and health personnel, concentrated in hospitals, clinics, and physical examination centers.

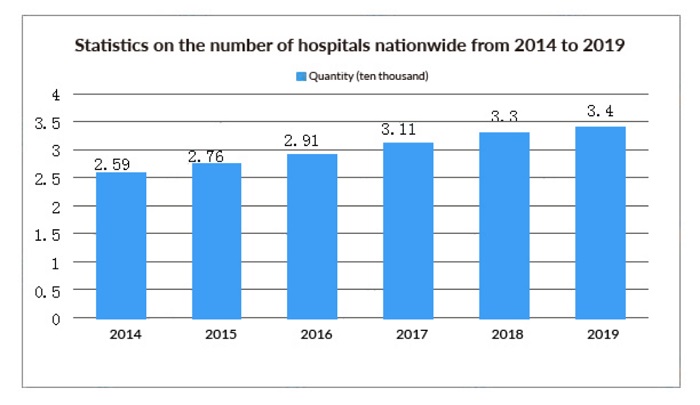

According to data from the National Bureau of Statistics, at the end of 2019, there were 1.014 million medical and health institutions nationwide, including 34,000 hospitals, 12,000 public hospitals, 22,000 private hospitals, and 96,000 primary medical and health institutions,among them, 36,000 township health centers, 35,000 community health service centers (stations), 267,000 outpatient clinics (stations), 621,000 village clinics; 17,000 professional public health institutions, including 3456 centers for disease prevention and control , 3106 health inspection centers (centers). In the future, with the continuous growth of medical and health institutions, the demand for disposable medical protective products will also increase, which will greatly promote the development of the disposable medical protective products industry.

Suntech's intelligent spunbond non-woven fabric machine helps the production of medical supplies such as masks, and the products can meet various needs.

(Suntech ST-ASS spunbond nonwoven machine)

Application field-beauty salon industry

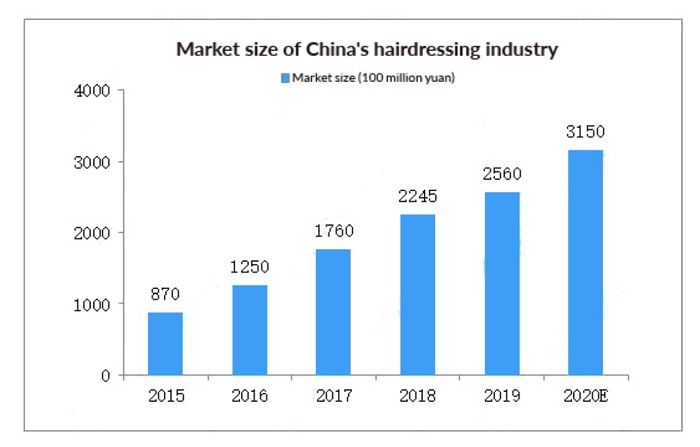

As the growth of the disposable income of Chinese residents stimulates consumption desire, the proportion of enjoyment consumption continues to increase. In China, the beauty and hairdressing industry has become the fifth largest consumption hotspot of residents after real estate, automobiles, tourism, and communications, and the industry is in a period of steady growth.

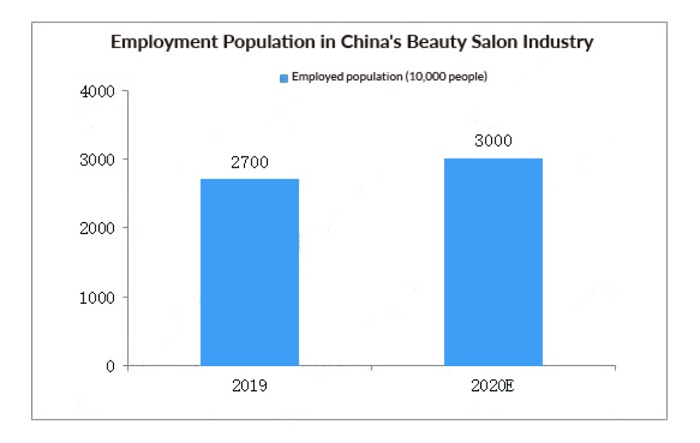

In 2019, there were 27 million people employed in my country's beauty and hairdressing industry, and in 2020, the number of employed people will exceed 30 million.

Since 2015, the market size of China's medical beauty industry has been in a trend of rapid growth. Now China has become the world's third largest medical beauty market. By 2020, the scale of China's medical beauty industry will reach 315 billion yuan. Although the medical beauty industry started relatively late in China, China's huge population base and strong consumption power have promoted the medical beauty industry to show its vitality in China. In the future, with the continuous expansion of the employment population and market size in the beauty and hairdressing industry, the demand for disposable protective products will also expand, and the demand for non-woven fabrics will further increase.

It can be seen that the future non-woven fabric market has a bright future. With 50 years of design experience and technology precipitation, suntech has been deeply involved in the field of hygiene and health, research and development and production of intelligent non-woven fabric machines, including spunbond non-woven fabric machines and spunmelted non-woven fabric machines. , Meltblown machine.All kinds of non-woven fabrics can be customized, please inquire for details.