Thriving in the fiercely competitive global market demands continuous innovation and strategic cost-cutting for garment manufacturers. Balancing cost reduction with maintaining quality and efficiency is a complex task, but there are several actionable strategies that can redefine the industry's approa

One pivotal shift in recent years is the evolution of sustainability from a mere buzzword to a business imperative. Garment manufacturers can now significantly cut costs by embracing sustainable practices across their supply chains. A key aspect is the adoption of sustainable and cost-effective materials like organic cotton, recycled polyester, and eco-friendly alternatives. This not only reduces raw material costs but also appeals to the growing segment of environmentally conscious consumers.

Another avenue for substantial cost-cutting lies in the implementation of energy-efficient technologies. Investing in modern machinery with lower energy consumption and optimizing production schedules to minimize energy usage during off-peak hours are effective strategies. Simultaneously, minimizing waste in the production process aligns with sustainable principles and trims material costs.

Lean manufacturing techniques play a crucial role in streamlining operations. Manufacturers can implement continuous improvement practices, empowering employees to identify and suggest solutions to enhance efficiency. Lean manufacturing also involves recycling waste materials and optimizing cutting patterns to reduce fabric wastage.

Production flow optimization, a part of lean manufacturing, involves the analysis and enhancement of production flow by eliminating bottlenecks and implementing efficient layouts. This can significantly improve overall productivity, reduce lead times, and cut costs. Cross-training employees on multiple tasks fosters flexibility in workforce allocation, maximizing efficiency without bloating staffing levels.

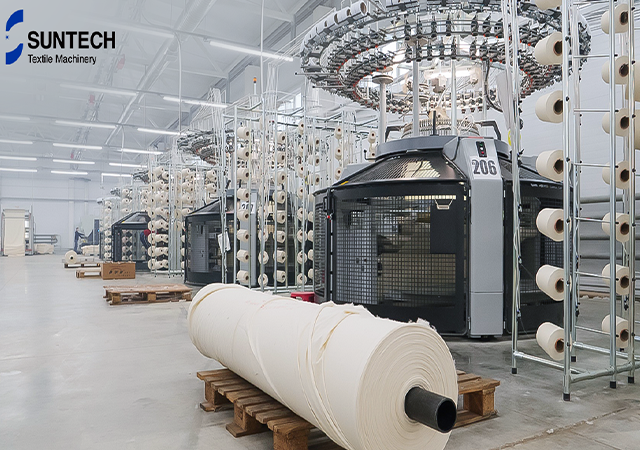

The adoption of technology and automation emerges as a game-changer for cost reduction and efficiency enhancement. While the initial investment may be substantial, the long-term benefits are noteworthy. State-of-the-art machinery, such as automated cutting machines, robotics, and computerized sewing machines, enhances precision and efficiency in production.

Enterprise resource planning (ERP) systems further streamline business processes, from inventory management to order processing. Digital prototyping tools accelerate the design process, reducing time and material wastage associated with traditional sample development.

Collaborative relationships with suppliers become a pivotal aspect of cost savings. Building strong partnerships with reliable suppliers facilitates negotiation of favorable terms, optimization of logistics, and ensures a steady supply of high-quality materials. Establishing long-term relationships and negotiating mutually beneficial contracts are key strategies in this regard.

Optimizing the supply chain by improving logistics and transportation efficiency is another avenue for cost reduction. Consolidating shipments, negotiating favorable freight rates, and exploring alternative transportation modes can significantly cut costs. Collaborative risk mitigation strategies with suppliers, including diversifying suppliers and maintaining contingency plans, address potential disruptions in the supply chain.

While cost reduction is imperative, it should not compromise product quality. Ensuring high-quality products can lead to long-term cost savings by reducing returns, rework, and warranty claims. Well-trained staff are more likely to produce error-free products, ultimately improving overall efficiency.

In the dynamic and competitive landscape of garment manufacturing, the pursuit of cost reduction remains crucial for sustainable growth and supporting better wages for garment workers—an outcome desired by all stakeholders.

SUNTECH Textile Machinery, a leading player in the industry, offers a comprehensive range of products, including fabric cutting machines, motorized beam trolleys, beam storage, and fabric relaxing machines. With an innovative approach and extensive experience, SUNTECH continues to spearhead advancements in the textile industry.