At present, the cumulative number of confirmed COVID-19 cases worldwide has exceeded 101.96 million, the cumulative number of deaths has exceeded 2.196 million, the number of newly diagnosed cases in a single day has exceeded 580,000, and the maximum number of new cases in a single day has exceeded 900,000. A new round of the epidemic is ushered in the winter. Now the United States and Europe have once again become the hardest hit areas. The epidemic in some areas has begun to run out of control, and the local medical system is overloaded.

Recently, the International Labor Organization (ILO) pointed out in the latest edition of the monitoring report "New Coronavirus and Global Work" that the global labor market has suffered unprecedented damage in the environment of the 2020 covid-19 pandemic. Lost working hours accounted for 8.8% of the total time, which is equivalent to the loss of 255 million full-time jobs. The loss was about four times the labor market loss during the 2009 global financial crisis.

The significant loss of working hours has caused global labor income to fall by 8.3% compared with 2019, equivalent to 3.7 trillion U.S. dollars, accounting for about 4.4% of the global gross domestic product (GDP) in 2019.

Many countries and people place their hopes on the covid-19 vaccine, hoping that the vaccine can alleviate the epidemic crisis. Recently, however, the British vaccine factory was threatened by a bomb. A warning zone has been set up near the vaccine factory in Wrexham Industrial Park. The British bomb disposal team has arrived at the scene. There have been no casualties, and the vaccine production capacity of the factories threatened by bombs has reached 300 million doses per year.

Europe and the United States are staged a vaccine "war", and developed countries are trying to monopolize the vaccine market despite the epidemic crisis. The White House ordered restrictions on vaccine exports, and the European and American covid-19 vaccines are suspected of increasing prices. Foreign media also revealed that with the support of France and Germany, Europe and the United States have decided not to sell the covid-19 vaccine. This is bad news for many countries that are unable to develop vaccines.

Now that there is such a shortage of vaccines, vaccines seem to have become exclusive to the rich. The best way for ordinary people to prevent the epidemic is still to wear masks. What kind of mask can effectively isolate bacteria? The quality of the mask depends on the quality of the melt blown cloth.

Melt-blown cloth is the heart of masks. At the beginning of the epidemic, melt-blown cloth was hard to find. The price of melt-blown cloth was increased many times, which once became the bottleneck of mask production. Many mask manufacturers have cut off supply of masks because they cannot produce melt blown cloth. What exactly is such a big-name meltblown cloth?

What is melt blown cloth?

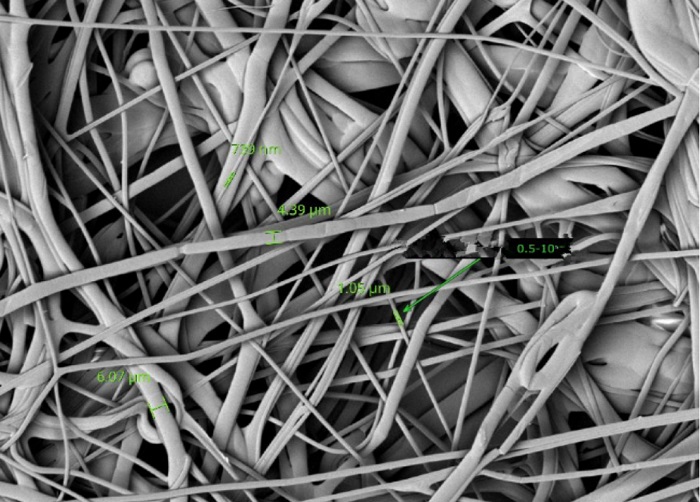

Melt blown cloth is the core material of the mask. The melt blown cloth is mainly made of polypropylene, and the fiber diameter can reach 1 to 5 microns. There are many voids, the structure is fluffy, and the ability to resist wrinkles is good. The ultrafine fiber with unique capillary structure can increase the number and surface area of the fiber per unit area, so that the meltblown cloth has good filterability, shielding, heat insulation and oil absorption. . It can be used in air, liquid filter materials, isolation materials, absorbing materials, mask materials, thermal insulation materials, oil absorbing materials and wiping cloths.(try Suntech Meltblown machine)

Melt blown cloth has a wide range of uses and can be used in the following fields:

1. Medical and health cloths: surgical gowns, protective clothing, disinfection wraps, masks, diapers, etc.;

2. Home decoration cloth: wall cloth, table cloth, bed sheet, bedspread, etc.;

3. Garment cloth: lining, adhesive interlining, wadding, shaped cotton, various synthetic leather base cloth, etc.;

4. Industrial cloth: filter material, insulating material, cement packaging bag, geotextile, covering cloth, etc.;

5. Agricultural cloth: crop protection cloth, seedling raising cloth, irrigation cloth, thermal insulation curtain, etc.;

6. Others: space cotton, thermal insulation materials, linoleum, cigarette filters, tea bags, etc.

How does spray cloth play a protective role?

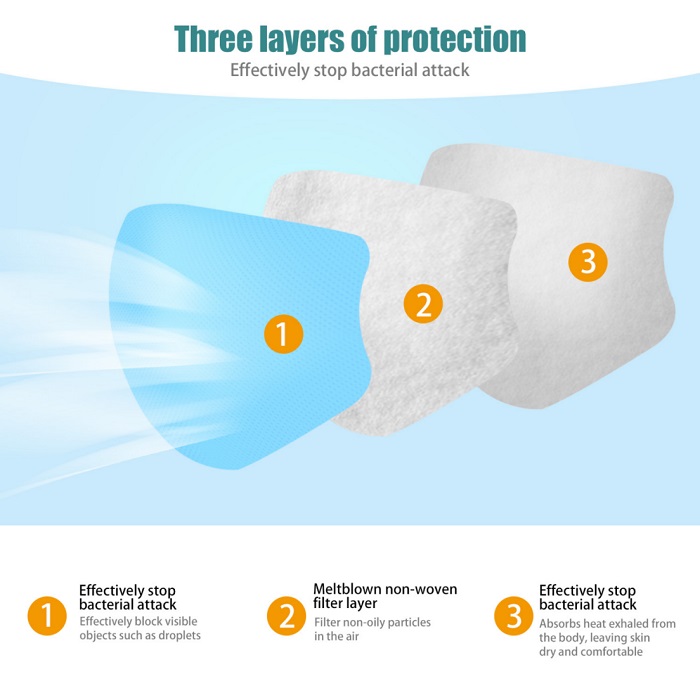

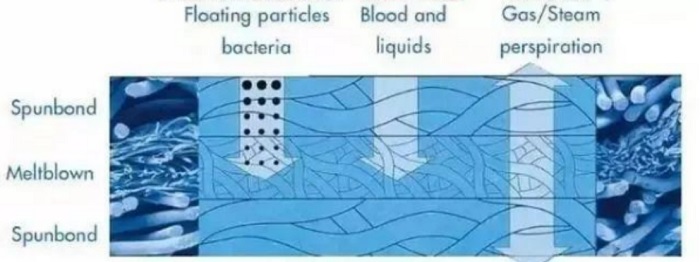

Masks that can play a role in epidemic prevention are basically non-woven materials, and the mask fabric is composed of spunbonded non-woven fabrics and melt-blown non-woven fabrics produced from polypropylene (PP). Medical masks are generally made of three layers of non-woven fabric: spunbonded non-woven fabric + meltblown non-woven fabric + spunbonded non-woven fabric, that is, SMS (2 layers of S and 1 layer of M) structure. The high strength of non-woven fabric (S) and the small difference in vertical and horizontal strength and the high shielding and waterproof performance of meltblown non-woven fabric (M) are concentrated on one material, forming a mask with strong waterproof performance, good breathability and efficient isolation.

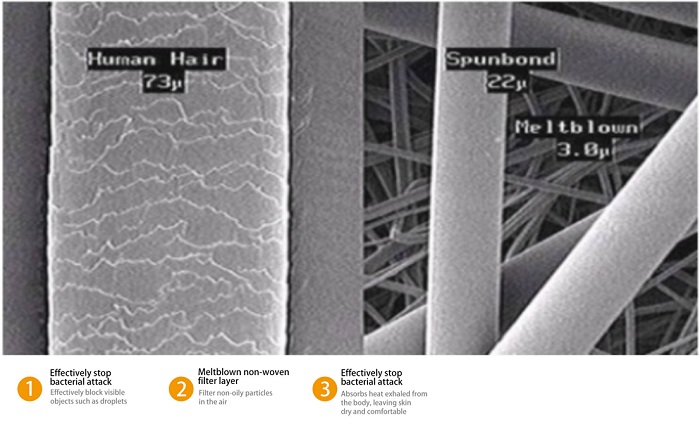

S stands for Spunbond, the fiber diameter is relatively thick, about 20 microns (μm), the outer layer S has dust and water blocking effect, can prevent droplets from entering the mask, the inner layer S has water absorption and can absorb The moisture in the wearer's nose and mouth, two layers of S spunbond support the entire non-woven structure.

The middle meltblown layer M (Meltblown) is the most important barrier layer. It is an extremely fine and electrostatic meltblown non-woven fabric. It is made of polypropylene with a high melt index and is composed of many criss-crossing layers. A film formed by stacking fibers in random directions, the fiber diameter ranges from 0.5 to 10 microns, and the fiber diameter is about one-thirtieth of the hair.

(Comparison of the diameter of hair, spunbond fiber and meltblown fiber)

(Structure of melt blown cloth)

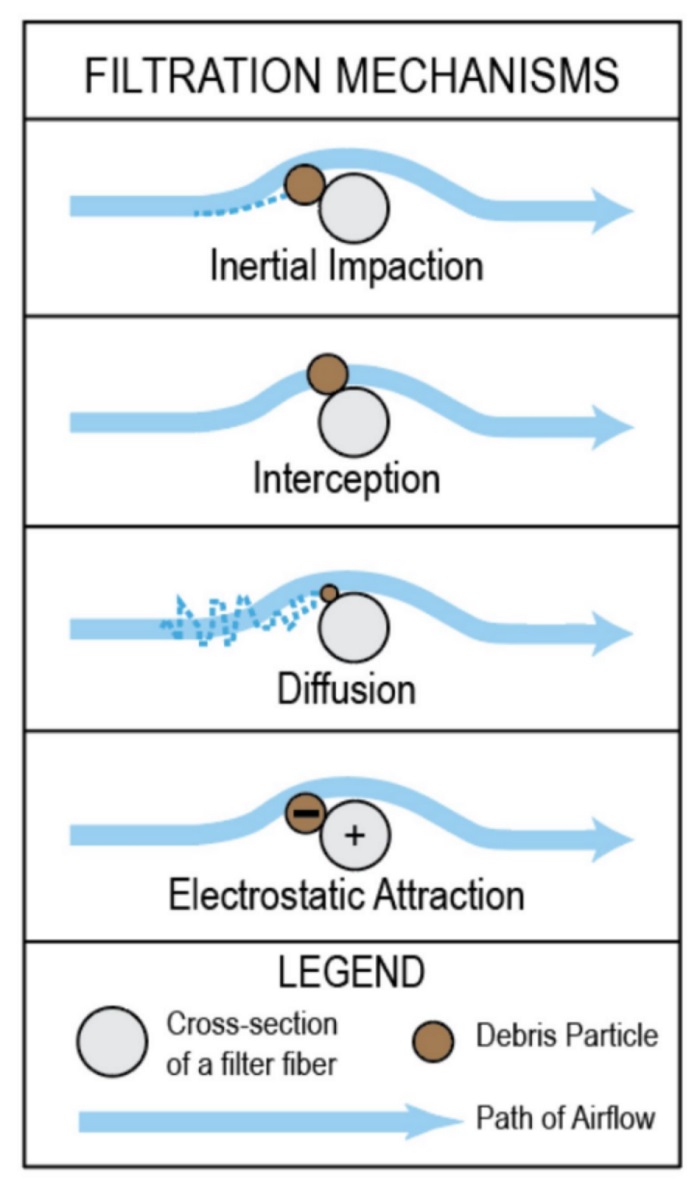

How does the meltblown cloth filter out viruses in the environment? Although the size of covid-19 is very small, about 100 nanometers (0.1 micrometers), the virus cannot exist independently. Its transmission routes are mainly secretions and droplets during sneezing. The size of the droplets is about 5 microns. The spray cloth is essentially a fiber filter. When the virus-containing droplets come close to the meltblown cloth, they will also be electrostatically adsorbed on the surface and cannot penetrate.

(Schematic diagram of fiber filtration mechanism)

When dust, droplets containing bacteria and viruses come close to the meltblown nonwoven fabric, they will be electrostatically adsorbed on the surface of the meltblown fabric and cannot penetrate. Since suspended particles such as dust are captured by the ultrafine electrostatic fibers, they are extremely difficult to be removed due to washing, and washing with water will destroy the electrostatic dust collection ability, so this mask can only be used once.

How to produce melt blown cloth?

The production process of melt blown cloth is very complicated, and its production process can be summarized into three parts: firstly, naphtha is extracted from petroleum, then chemically processed into polypropylene, and finally made into cloth by melt blown process. The specific process includes melt extrusion Out, melt blown process and electret treatment.

Is the meltblown cloth really sprayed out?

Although the S layer and M layer of the mask are made of special polypropylene resin, the special materials for meltblown cloth and other non-woven fabrics are very different in production technology and performance. It can be said that the M-layer meltblown cloth is sprayed out.

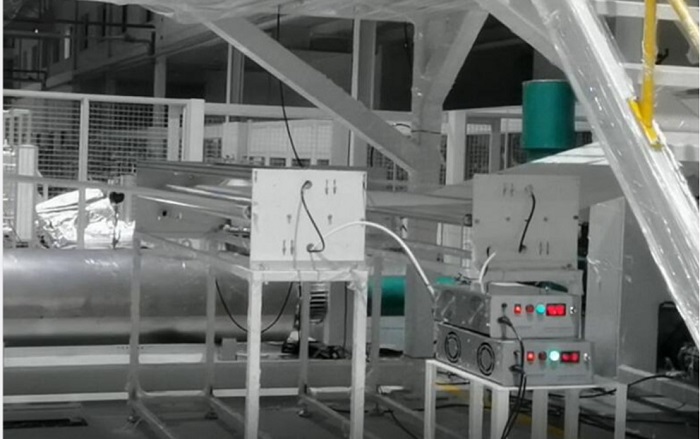

Melt blown cloth is to use high-speed hot air flow to draw the thin stream of polymer melt extruded from the orifice of the die, thereby forming ultra-fine fibers and collecting them on the net curtain or roller, and at the same time bonding themselves to become Meltblown non-woven fabric. Suntech intelligent melt blown machine assists the production of melt blown cloth with the standard of "precision manufacturing".

The process is similar to making marshmallows. Pour the melted syrup into the container of the marshmallow machine. The syrup will be stretched into thin sugar strands due to high-speed rotation. These sugar strands will quickly condense and solidify when encountering colder air, and they will condense together to form a solid. Flocculent cotton candy.

For the production of meltblown cloth, the machines used are more complex and the raw materials used are more demanding. It uses a molten polymer (such as polypropylene). Polypropylene is a thermoplastic synthetic resin with excellent performance. It is a colorless and translucent thermoplastic lightweight general-purpose plastic with chemical resistance, heat resistance, and electrical insulation. High-strength mechanical properties and good high wear-resistant processing performance; based on this performance, the raw material of melt blown cloth can be sprayed out of a mold with many small nozzles under high pressure. Therefore, the meltblown cloth is really "sprayed out".

The special material for melt blown cloth is polypropylene with high melt index. The higher the polypropylene melt index, the finer the melt-blown fibers and the better the filterability of the melt-blown cloth made.

Electret treatment

Electret refers to a dielectric material with long-term charge storage function. It has the advantages of high efficiency, low flow resistance, antibacterial, and energy saving. On the basis of ensuring the physical collision blocking effect of conventional filter materials, it adds electrostatic adsorption. The electret treatment makes the filter material fibers charged, combined with the dense characteristics of meltblown ultrafine fiber materials, so a large number of electrodes are formed between the charged fibers. The charged fibers can not only attract most of the charged particles in the environment like a magnet, but also Part of the uncharged particles can be polarized, and then some pollutants with a smaller particle size can be adsorbed. Even the nano-scale materials such as viruses can be electrostatically adsorbed or blocked by charge repulsion.

The meltblown cloth used for medical masks must be electret treated. Sterile medical masks are sterilized by ethylene oxide. After sterilization, there will be residues of ethylene oxide on the mask, which not only irritates the respiratory tract, but also causes carcinogens. The analysis method must be used to release the residual ethylene oxide to meet the safety content standard. The entire standard process of analysis and disinfection takes 7 days to half a month.

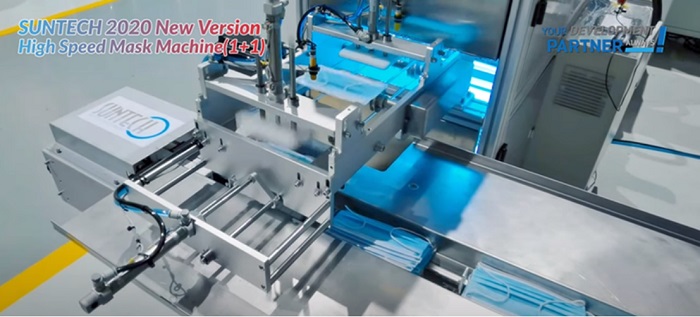

Suntech smart mask machine adopts UV sterilization, no analysis is required, and the masks produced can be used directly, saving time and effort. At the same time, it is equipped with an online inspection function to automatically remove unqualified masks, greatly improving production efficiency.

Melt blown cloth inspection

At present, the focus of meltblown cloth testing generally includes the three steps of appearance quality, internal quality and microbiological index testing. Melt blown cloth mainly has the effect of filtering viruses in masks, but how to ensure the quality of polypropylene special materials for mask melt blown cloth is a problem that most businesses care about. Its key index molecular weight distribution can be used as a quality control method to provide a technical reference for the optimization of meltblown production process and product quality control. The national standard GB/T 30923-2014 puts forward clear requirements on the molecular weight distribution of melt blown materials. The processing method of melt blown materials requires that the molecular weight distribution of melt blown materials is as narrow as possible and uniform as possible.

(Suntech ST-AMB Melt blown machine)

Suntech smart melt blown spinneret adopts Japan's leading technology, using German Demag CNC machining center and Italian Fidia gantry five-axis high-speed milling, and fluid polishing. The diameter of the spinneret can reach 0.25mm, and the air-drawing is 1-4μm. The spinneret is thin and uniform, which is enough to ensure the filtration and air permeability of the meltblown cloth.

With 50 years of technical precipitation and design experience, Suntech has developed and manufactured mask machines, meltblown machines, and smart mask machines. One piece of equipment covers the entire process of mask production. The maximum production speed can reach 160 pieces/min. The meltblown machine adopts advanced technology and spinning. Fine and uniform, to ensure the output quality of melt blown cloth, please inquire for details.