One of the critical quality control steps in the textile industry is fabric visual inspection, which is the process of examining fabrics for defects before they are shipped to customers. In recent years, the textile industry has seen significant advances in technology, including automated fabric visual inspection defects systems. This blog will explore the importance of fabric visual inspection and the benefits of using automated fabric visual inspection defects systems.

Fabric Visual Inspection Defects System

Fabric visual inspection is a crucial step in the textile production process. It involves examining fabrics for defects such as holes, stains, and tears, which can affect the quality of the final product. Fabric defects can occur due to a variety of reasons, including manufacturing errors, transportation damage, or improper storage. Detecting and addressing these defects before the fabric is shipped to customers is critical to ensuring that the final product meets the quality standards set by the industry.

The fabric visual inspection defects system is a quality control process that involves manually inspecting fabrics for defects. This process requires skilled workers who can detect defects and make decisions about whether the fabric is suitable for use. The fabric visual inspection defects system is time-consuming and can be prone to errors, especially if the worker is fatigued or distracted.

Automated Fabric Visual Inspection Defects System

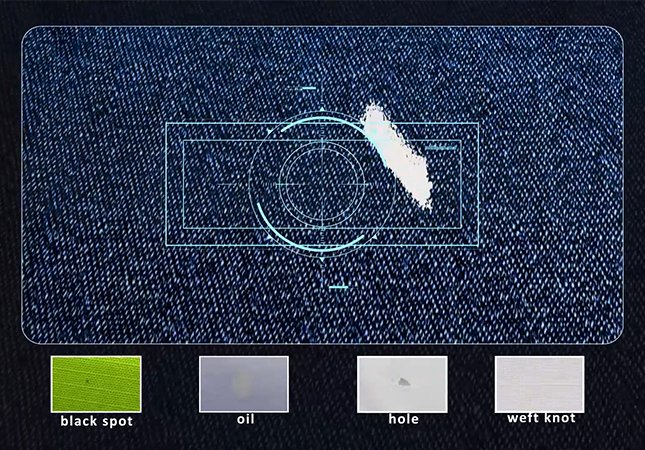

Automated fabric visual inspection defects systems use advanced technologies such as computer vision and machine learning to detect defects in fabrics. These systems can analyze fabrics at high speeds and with high accuracy, reducing the time and cost of the inspection process. Automated fabric visual inspection defects systems work by capturing images of the fabric using high-resolution cameras. The images are then analyzed using computer algorithms to detect defects such as holes, stains, and tears. Machine learning algorithms can be used to improve the accuracy of the defect detection process over time, allowing the system to learn from its mistakes and improve its performance.

Benefits of Automated Fabric Visual Inspection Defects System

To address the limitations of the manual fabric visual inspection defects system, the textile industry has turned to automated fabric visual inspection defects systems. There are some benefits of an automated fabric visual inspection defects system.

l First, an automated fabric visual inspection defects system is faster and more accurate than manual inspection methods, allowing manufacturers to inspect fabrics more quickly and with greater precision, helping to reduce production costs and improve the quality of the final product.

l Second, an automated fabric visual inspection defects system can detect defects that might be missed by manual inspection methods and is able to improve the overall quality of the final product, reducing the risk of customer complaints and returns.

l Finally, an automated fabric visual inspection defects system is able to ensure the reduction of the risk of worker fatigue and injury associated with manual inspection methods by automating the inspection process, so that the workers can be freed up to perform other tasks, reducing the risk of repetitive strain injuries and other work-related injuries.

Conclusion

Fabric visual inspection is a critical quality control step in the textile industry, ensuring that the final product meets industry standards and customer expectations. The fabric visual inspection defects system is a manual inspection process that is prone to errors and can be time-consuming. Automated fabric visual inspection defects systems offer several benefits, including increased speed and accuracy, improved defect detection, and reduced worker fatigue and injury. As the textile industry continues to evolve, automated fabric visual inspection defects systems will likely become more prevalent, helping to improve the quality of textile products and streamline the production process.

SUNTECH provides the textile industry machines to the whole world, helps them to improve the efficient, decrease the labor costs. SUNTECH's ST-ACI-I automatic camera inspection system ( for Fabric Inspection Machine ) is the newest product of SUNTECH, and is known for its outstanding outcomes, qualified and praised by customers in China and abroad. Moreover, SUNTECH offers numerous types of textile machinery: visual inspection defects, fabric measure and cutting machine, fabric swatch cutter, beam truck, trolley lift system, fabric roll cutting machine etc. If you are interested in us, please contact us now!