Recently, the President of the Dallas Medical Association, Dr. Mark Kazanova, and Ron Koning discussed COVID mutations. A variant of the British coronavirus caused panic because it may spread more easily. But even if this turns out to be the case, experts say that the upcoming COVID-19 vaccine may still work against this variant.

Dr. Anthony Fauci, a top US infectious disease expert, said that data from the United Kingdom show that vaccines can still block the virus. But the United States will also conduct tests to determine this.(Click to share to LinkedIn)

As the virus reproduces and moves in the population, small changes often occur. In fact, these small changes are how scientists track the spread of the virus from one place to another.

But if a virus mutates sufficiently, people are worried that current vaccines may no longer provide that much protection. Although this is a possibility of observing the coronavirus, experts say they don't believe the British mutation will be like this.

"My expectation is that this will not be a problem," said moncefslaoui, chief scientific adviser for the promotion of the COVID-19 vaccine in the US government.

Covid-19 is very cunning and mutates quickly. The applicability, degree of epidemic prevention and safety of the vaccine to the mutated virus will require a period of verification. At present, the safest and most effective method is still to wear a mask. Vaccines can only strike accurately at close range, but masks can block most suspicious viruses on a large scale.(Click to share to Facebook)

.jpg)

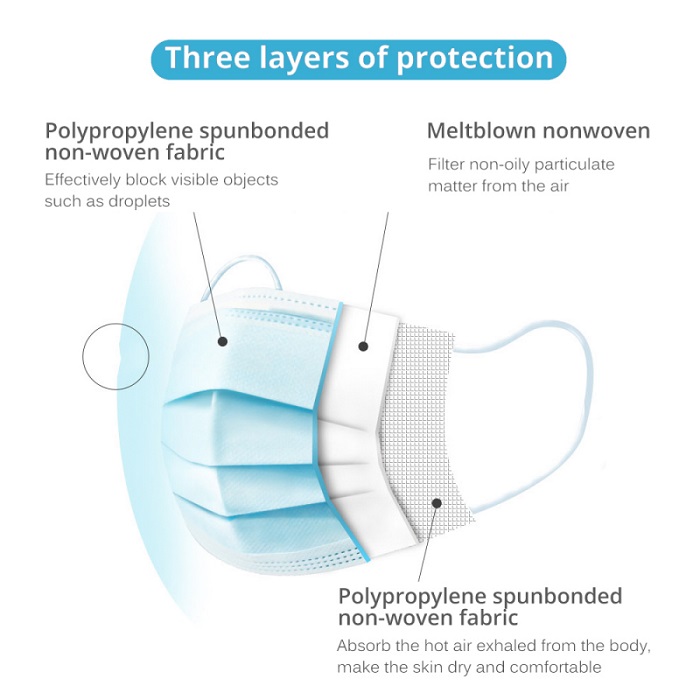

How do masks protect against germs?

General surgical masks are divided into three layers, a waterproof layer, a filter layer, and a comfort layer. The filter layer is a melt blown cloth with electrostatic adsorption, which is self-charged and can effectively adsorb bacteria. And the electric charge is provided by electret, so what is electret? In layman's terms, any material or substance that can store charge for a long time can be considered an electret.(Suntech Meltblown machine adopts electret treatment)

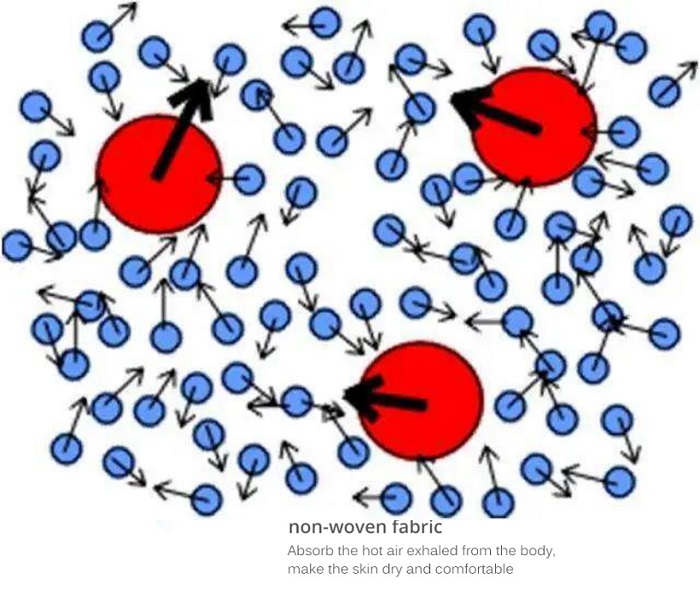

In the process of air filtration, electrostatic adsorption relies on Coulomb force to directly attract and capture charged particles in the gas phase, or induce neutral particles to generate polarity and then capture them, which can more effectively filter the sub-micron particles in the gas carrier phase , Effectively enhance the filtration efficiency, but the air resistance will not increase. This is the so-called effective low-resistance filter material. The electret material has exactly this property.

The development history of electret

In 1963, scientists Karl Ziegler and Giulio Natta won the Nobel Prize in Chemistry for their contributions to coordination polymerization catalysts and the synthesis of isotactic polypropylene. , 68 years have passed since the birth of medical sterilized gauze masks.

15 years later, the polypropylene meltblown cloth electret used in modern masks was invented by the well-known 3M company in the field of protection and applied for a patent. In 1981, 3M used the material for the first time in the field of air purification, and then applied for many patents related to masks. This also laid the foundation for modern masks to use polypropylene meltblown cloth (electret) as the core filter layer, and then eliminated and replaced sterile gauze masks.

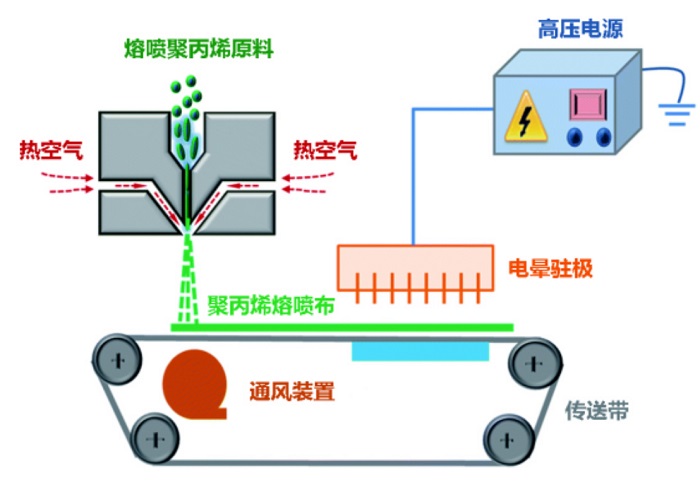

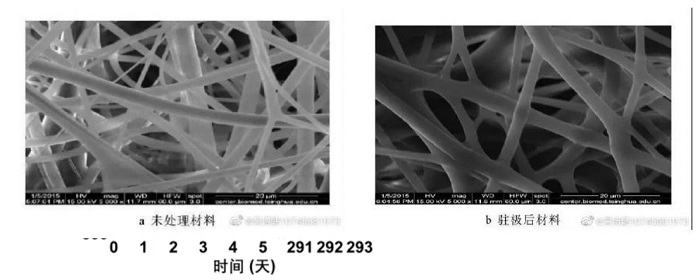

Since the first artificial electret was prepared in 1919, many excellent electret materials have been discovered one after another, among which is polypropylene, a petrochemical product in a large quantity and a wide range. In industrial production, the corona electret method is generally used to inject charges into the polypropylene meltblown fabric. As shown in the figure below, the injected charge will stay in the meltblown fiber for a very long time at room temperature.

(Polypropylene meltblown cloth preparation and corona electret process)

Charge of melt blown brie

The charge in polypropylene fiber is mainly divided into two types. One is the charge that is easier to run away, and it will run away at about 70°C. The other is relatively stable in the material. This part of the charge needs to reach 100°C. Will run away slowly.

The important feature of a good electret melt blown cloth is that the charge is relatively stable at high temperatures. Because the electric charge is divided into positive and negative, so when electret can use positive voltage electret or negative voltage electret, but the experimental results show that the charge after negative voltage electret is more stable, so it is used in general industrial production. Electret with negative voltage. In the negative electret process, the charge injected into polypropylene is mainly carbonate ions and oxygen anions.

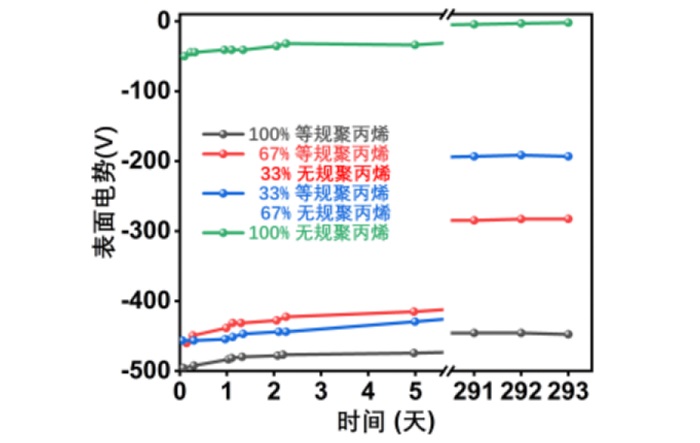

The charge storage time injected into polypropylene has a great relationship with the crystallinity of the polypropylene material. The higher the crystallinity, the more charge injected and the more stable the charge. Some researchers used isotactic polypropylene that is easy to crystallize and non-crystalline atactic polypropylene to mix in different proportions. It was found that the more isotactic polypropylene, the longer the charge storage time at room temperature, even when the storage time is as high as 290 days. The surface potential has only attenuated by about 10%, as shown in the figure below.

(The influence of different isotactic polypropylene content on charge stability)

It can be seen that there are two ways to improve the charge storage capacity of electret materials:

1. By improving the crystallinity and mechanical deformation of the material, the structure of the material is changed to form a slender hole channel to prevent charge drift.

2.By introducing an additive (tourmaline) with charge storage properties to generate charge traps to capture charges, and to generate a weak current for a long time to form an electrostatic field.

Suntech meltblown machine comes with electret treatment: after the fiber is ejected from the 0.25mm spinneret hole, it is drawn in the air by 1-4μm, and the spinning is fine and uniform, and then bombarded by charged protons such as electrons or ions, making the fiber The material becomes an electret, using high crystallinity material with optimal temperature control to ensure the electret treatment effect. Ensure that the produced melt blown cloth has good electrostatic adsorption, filtration and air permeability.