Over the past decade, China's textile machinery industry has undergone significant transformations, mirroring the global shifts in textile manufacturing and consumption patterns.

Since 2013, the global textile machinery market has witnessed a surge in demand for Processing Machinery, encompassing a wide range of functions such as washing, cleaning, drying, ironing, dyeing, and finishing textile products. This category accounted for approximately 26.37 percent of global textile machinery imports, solidifying its position as the most sought-after segment. Notably, the Processing Machinery segment experienced a steady compound annual growth rate (CAGR) of 3.43 percent from 2004 to 2013, indicating sustained growth.

In addition to Processing Machinery, sewing machinery plays a pivotal role in adding value to the textile value chain. The garment/made-ups segment has seen substantial investments from the textile and clothing industry, driving higher import demand for machinery related to processing and garment production.

Rising Nonwoven Industry

The nonwoven sector within the textile machinery market has been gradually gaining traction. Machinery related to the manufacture and finishing of nonwovens, including felt and hat production, has recorded a significant CAGR of 6.42 percent from 2004 to 2013. This growth underscores the increasing significance and potential of the nonwoven sector in the textile machinery market.

Manmade Textiles Machinery: This segment involves machinery for extruding, drawing, texturing, or cutting man-made textile materials. In 2013, global imports for this segment were valued at US$ 1317.89 million, contributing approximately 5.34 percent to the total textile machinery imports. China stands as the major importer, followed by India, Turkey, the United States, and Brazil. The manmade textile industry is rapidly growing in countries like Pakistan, Taiwan, Brazil, India, and Malaysia, as evidenced by double-digit growth rates in machinery imports.

Spinning/Pre-Weaving Machinery: This segment includes machinery for preparing textile fibers, spinning, and twisting. In 2013, global imports amounted to US$ 3061.20 million, making up around 12.39 percent of total textile machinery imports. China, followed by India, Bangladesh, Indonesia, and Turkey, leads the global import in this category. The spinning/pre-weaving industry is thriving in countries like Korea, India, and Bangladesh, with double-digit growth rates in machinery imports.

Weaving Machinery: Comprising machines for preparing textile fabrics, especially looms, this segment accounted for approximately 7.14 percent of total textile machinery imports in 2013. China leads the global import in this category, followed by India, Turkey, Iran, Bangladesh, and Indonesia. Notably, Bangladesh's weaving industry is growing rapidly, reducing its reliance on fabric manufacturing nations like China, India, and Pakistan.

Knitting Machinery: This segment encompasses knitting machines, stitch-bonding machines, and more. In 2013, global imports for this segment were valued at US$ 2871.19 million, contributing around 11.63 percent to total textile machinery imports. China, India, Bangladesh, and Turkey are major importers. The knitting industry is experiencing growth in Brazil, Bangladesh, and India.

As of the first half of 2023, China's textile machinery industry is experiencing stability in sales of spinning-related machines due to robust domestic demand. While exports have witnessed a downturn, domestic sales remain strong.

High-speed carding machines and combing machines have seen a 5.1 percent increase in sales.

Sales of spinning draw frames fell by 8 percent year-on-year.

Roving frames experienced a 4.2 percent year-on-year decline.

Ring-spinning machines witnessed a 10 percent increase in sales.

Automatic winding machines and short fiber twisting machines saw a drop in sales.

The future of China's textile machinery sector is likely to be shaped by several key factors:

Technological Advancements: Expect continued innovation and automation in textile machinery, enhancing efficiency and reducing labor costs.

Sustainability: The industry will likely place greater emphasis on sustainable and eco-friendly production methods, driven by environmental concerns and consumer demand.

Global Market Dynamics: China's textile machinery exports may rebound as global demand for textiles and apparel fluctuates.

Digital Transformation: Integration of digital technologies like IoT and AI into textile machinery may redefine production processes and supply chain management.

Regional Growth: Keep an eye on emerging markets like Bangladesh and Brazil, which are poised for further growth in textile manufacturing.

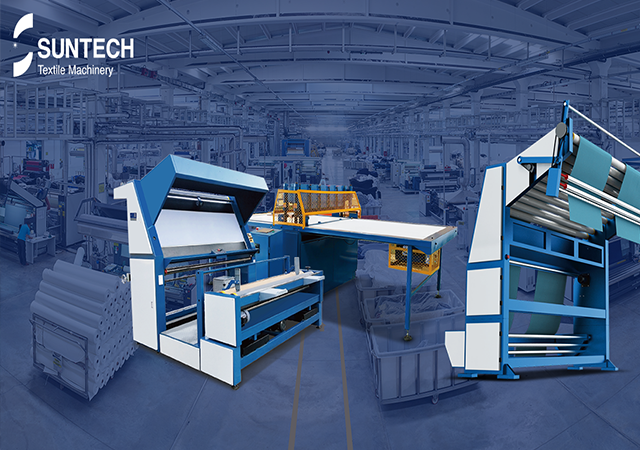

SUNTECH Textile Machinery is leading the technological transformation of the textile industry, injecting innovative forces into the field. Through continuous research and development and technological innovation, SUNTECH Textile Machinery has propelled the development of the entire supply chain in the textile machinery industry and delivered remarkable achievements to the global textile industry.