In July 2023, Bangladesh celebrated a 17.43% increase in its garment exports, totaling an impressive $3.9 billion. This seemed like a remarkable achievement, solidifying its position as one of the world's top apparel exporters. However, a looming warning signaled that the recent surge in orders was straining the capabilities of Bangladesh's textile industry.

Looking back to 2022, Bangladesh had already established itself as the second-largest global apparel exporter after China, with exports reaching $46.99 billion, surpassing Vietnam's $35 billion. Yet, the industry was grappling with internal challenges. Despite the capacity to fulfill large orders, many mills were operating below potential due to issues like inadequate gas and power supply and a banking sector struggling with a dollar crisis. Production in several mills had declined by a staggering 50%.

However, despite these hurdles, Bangladesh's garment, textile, and accessories manufacturers were undeterred. They were preparing to invest a substantial Tk12,000 crore over the next two years in cutting-edge technologies that promised to revolutionize the industry.

This visionary approach was driven by several key trends in the textile industry. Firstly, there was a growing demand for personalized textiles, from T-shirts to jackets, highlighting the need for uniqueness and individuality. Secondly, the digitalization and automation of production processes were on the rise, making small and medium-sized businesses more competitive. Lastly, sustainability was a paramount concern, encompassing the entire production chain.

In response to shifting consumer buying patterns, apparel and textile manufacturers were under pressure to reduce delivery times and manage fragmented orders. This trend was leading to higher inventories and increased overhead costs. Furthermore, sustainability had become the central issue facing the global fashion industry, necessitating unique approaches and plans.

Bangladesh's labor policies and safety measures had made progress, but concerns persisted about low wages paid to garment workers, even as the Western fashion industry thrived on their labor.

Amid these challenges, Bangladesh needed to diversify its export base and solidify its position as a significant manufacturing hub. Integrating sustainability into textile and apparel production was a crucial step in this direction, starting with the adoption of advanced and eco-friendly machinery.

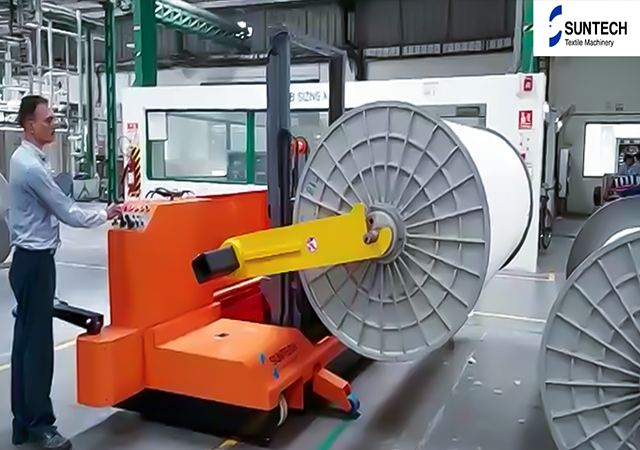

One such innovation was the SUNTECH Electric Warp Beam Truck, designed specfically for terry towel looms. This truck featured remarkable capabilities, including side shift functions, a high carrying capacity, generous lifting height, and eco-friendly gel batteries. These attributes not only improved efficiency but also aligned with the growing focus on sustainability.

Looking ahead, the material handling equipment industry was evolving to meet dynamic business needs. Automation, flexibility, safety, and sustainability were the cornerstones of this evolution. Manufacturers were integrating features that enhanced productivity, adapted to changing demands, improved workplace safety, and aligned with global sustainability goals.

In conclusion, Bangladesh's textile industry had shown resilience and determination in the face of challenges. As the industry continued to evolve and embrace technological advancements, the path forward was clear: a commitment to sustainability, improved efficiency, and a relentless pursuit of excellence would ensure its enduring success on the global stage.