Fabric relaxing machines play a pivotal role in the garment industry by effectively applying tension to fabric, ensuring it's relaxed or stretched as needed. These machines consist of two rotating rollers, with one positioned above the other, rotating in opposite directions. The fabric passes through these rollers, where tension is applied to achieve the desired outcome.

Industries such as textiles and garments greatly benefit from fabric relaxing machines. Textile businesses use these machines to prepare fabrics before weaving or knitting, while garment manufacturers employ them to stretch fabrics before cutting or sewing. The significance of fabric relaxing machines in achieving high-quality garments cannot be overstated.

- The Fabric Relaxing Process

Input and Configuration: Operators begin by inputting the fabric's width and yardage into the machine. They then adjust the roller gap to determine the required tension.

Roller Alignment: The lower roller is raised and brought into contact with the upper roller, creating a controlled tension zone.

Fabric Feeding: With the machine activated, the operator slowly feeds the fabric into it. As the fabric travels through the rollers, the predetermined tension is applied, resulting in relaxation or stretching.

Finishing Touches: After passing through the machine, any excess fabric is trimmed off, and if necessary, pieces are sewn together.

- Benefits of Fabric Relaxing Machines

Enhanced Fit: Achieving the perfect fit for garments is crucial. Fabric relaxing machines ensure that fabrics are appropriately stretched or relaxed, contributing to well-fitting garments.

Professional Finishing: These machines aid in creating garments with a polished appearance by adding creases, pleats, or eliminating wrinkles.

Fabric Shrinkage Control: Fabric relaxing machines can also shrink fabric, making it fit better in specific areas, such as the waistline, enhancing the overall garment fit.

Ease of Use and Low Maintenance: These machines are user-friendly and require minimal maintenance, making them a cost-effective solution for garment businesses.

- Varieties of Fabric Relaxing Machines and Their Functions:

Rotary Fabric Relaxer: Ideal for delicate fabrics, this machine employs a rotating drum to smooth out wrinkles and can adapt to various fabric types.

Pneumatic Fabric Relaxer: Using air pressure, this machine is suitable for thicker fabrics or multiple layers, with adjustable settings for different fabric varieties.

Steam Relaxer: This machine utilizes steam to relax fabric fibers and remove wrinkles. It's effective for heavily wrinkled or starched fabrics.

- Utilizing a Fabric Relaxing Machine

1. To maximize the benefits of a fabric relaxing machine, follow these steps:

Read the Instructions: Familiarize yourself with the machine's guidelines to ensure correct usage and optimal results.

Ventilation: Operate the machine in a well-ventilated area due to emitted fumes during operation.

Setup: Follow instructions for machine setup, including filling the reservoir with water and appropriate solutions.

Operation: Run the machine for the recommended duration based on fabric type.

Cool Down: After completion, allow the fabric to cool before handling.

2. Safety and Best Practices:

Grounding: Ensure the machine is grounded before operation.

Instruction Review: Thoroughly read and follow manufacturer instructions.

Supervision: Never leave the machine unattended while operational.

Maintenance: Regularly maintain the machine to prevent accidents or malfunctions.

3. Troubleshooting and Maintenance:

If issues arise with the fabric relaxing machine;

Check roller tension to ensure even fabric feeding.

Adjust steam pressure to avoid fabric damage.

Clean lint filters and descale the boiler to maintain performance.

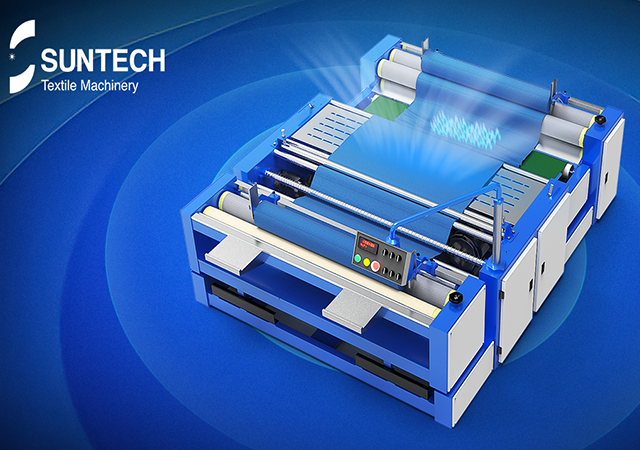

- About SUNTECH Fabric Relaxing Machine

After several generations of technology iterations, SUNTECH Textile Machinery launched the Roll to Roll Fabric Relaxing Machine(5th Generation) ST-FRM-VI: Specifically designed for garment factories, this roll-to-roll fabric relaxing machine ensures tension elimination for various fabrics, including knits, elastomeric, lycra, and denim. It streamlines the manufacturing process, saving time and enhancing quality.

- Conclusion

Fabric relaxing machines are indispensable tools in the garment industry, boosting efficiency and quality. By investing in technology like the SUNTECH ST-FRM-VI, garment manufacturers can ensure smoother fabric finishes, faster production, and improved competitiveness. The advantages span from achieving optimal fit and professional finishing to cost-effective operation and ease of use. When properly operated and maintained, fabric relaxing machines significantly contribute to elevating garment production standards.