In the dynamic world of textile manufacturing, knitting factories stand at the forefront, leveraging advanced machinery to diversify and refine their product offerings. At the core of these operations are sophisticated knitting machines, essential for transforming yarn into high-quality knitted fabrics. These machines come in various sizes and capabilities, tailored to meet the demands of modern textile production.

Beyond knitting machines, the industry employs various other textile equipment to ensure seamless operations and superior product outcomes. Looms, sewing machines, and a suite of automated systems are integral to the manufacturing process, each playing a pivotal role in fabric creation and garment assembly.

The Advantages of Automation in Textile Manufacturing

Automation has reshaped the landscape of knitting factories, primarily by enhancing the speed and efficiency of production lines. This technological advancement not only increases output but also improves the quality of the final products, thanks to the precise and consistent nature of automated systems. By reducing the reliance on manual labor, factories can minimize human error and significantly cut labor costs. Moreover, automation allows for the execution of complex tasks that are either too challenging or tedious for human workers.

Exploring the Types of Textile Machinery Used in Knitting Factories

Looms: Vital for the weaving process, looms interlace warp and weft threads to create textiles. Modern factories use a range of looms, from traditional handlooms to highly efficient automatic or power looms.

Spinning Machines: These are crucial for twisting fibers into yarn, featuring components like roving frames and spinning frames, essential for controlling yarn thickness and twist.

Fabric Winding Machines: Post-spinning, these machines wind the yarn onto bobbins or cones, preparing them for knitting or storage.

Yarn Preparation Machines: Including cone winders and ball winders, these machines ready the yarn for knitting by performing essential tasks like winding, twisting, and cleaning.

Dyeing Machines: To add color, dyeing machines such as jet and beam dyeing machines are used, capable of processing yarn and fabric in a multitude of shades.

Finishing Machines: To improve fabric quality and appearance, finishing machines perform various functions, from brushing and shearing to thorough inspections.

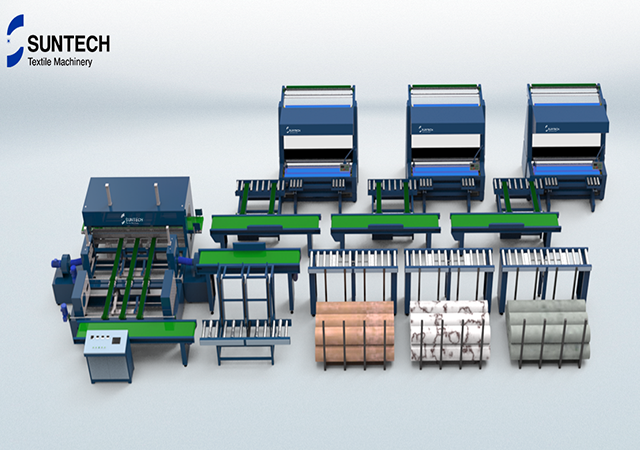

SUNTECH: A Leader in Textile Machinery for Knitting Factories

SUNTECH stands out with its comprehensive range of knitting factory solutions, including automatic packaging machines, fabric inspection machines, and tubular fabric slitting machines. Known for their quality and reliability, SUNTECH also offers material handling equipment, enhancing the efficiency and safety of transporting heavy materials within the factory.

The utilization of specialized textile machinery in knitting factories is not just about automation; it's about revolutionizing the way textiles are produced. From enhancing efficiency and quality to reducing costs and manual labor, these machines are the backbone of modern textile manufacturing, ensuring that factories can keep up with the demands of a competitive market.