Textiles are a labor-intensive industry. Although the technical content is not high, it is always an important industry in all countries and plays a pivotal role in the economies of all countries. Because the biggest contribution of the textile industry to the global economy is to solve a large number of labor employment problems.

China is the world’s largest textile producer and exporter. According to the statistics of the Textile Industry Association, China’s fiber processing capacity will be 24 million tons in 2020, accounting for about 38% of the world’s production capacity. The textile industry is one of the traditional manufacturing industries that absorb the most employment. China's textile industry currently employs 18 million people directly and more than 100 million people indirectly...

Although the software industry that India is proud of has also contributed to India’s economic development, the number of people benefiting from it accounts for a very small proportion of the total population.No matter how fast India’s software technology develops, it is impossible to replace the textile industry with the software industry. The textile industry still occupies an important position. It must use existing technology to assist the transformation and innovation of the textile industry and achieve the upgrading and development of the textile industry in order to lead the world.(try suntech Rapier loom)

Textile technology development history

Whether the textile industry is advanced or not depends mainly on the development of textile technology. The earliest textile technology originated from the silk weaving that appeared in the long-term basin of the Yellow River in the first century BC. Hand spinning wheels and pedal looms appeared one after another. The original loom has a simple structure, but it can embody the basic principles of fabrics, which also signifies that humans have entered the era of wearing textiles. The common primitive looms are: primitive waist knitting machine, vertical knitting machine, heald loom and so on.

Later, the British invented the shuttle weaving technology, which is nearly twice as fast as manual, and can increase the width of the weaving. With the beginning of the textile industry, Western countries began to use steam engines to drive textile machines at the end of the 18th century. In 1895, it was developed into an automatic changing device to form an automatic changing loom. In 1926, it was developed into an automatic shuttle changing loom. By the 20th century, it developed into a projectile loom without a pipe and a spray paint spraying machine.

During the development of the textile industry, various forms of shuttleless looms appeared, including rapier looms, projectile looms, air jet looms, water jet looms, multiphase looms, magnetic weft insertion looms, etc. . From the perspective of the technological development of international shuttleless looms and the needs of the textile industry, air-jet looms have made rapid progress in terms of high-speed, wide-width, and serialization. They are increasingly widely used in yarn-dyed, jacquard and other fabrics. It has advantages in terms of variety adaptability, variety of fabric colors, and a wider range of suitable weaving. Rapier looms have gradually become the most widely used model in the textile industry and have gradually become a trend.

Pain points in the textile industry

1. The loom does not match the grade of the product. Some companies have introduced many high-end rapier looms, but used them to produce low-value-added mid-range and even low-end fabrics, failing to perform the functions of high-end looms. The main reason is that the imported equipment is not matched and cannot form productivity.

2. There is no high-grade, high-quality yarn. For example, in the silk industry, advanced countries all produce real silk fabrics with higher than 3A grade factory silk, while most developing countries use 2A grade factory silk to produce similar products, because the weft insertion rate is only 1/2-1/ of the design level. 3. Production efficiency and product quality are very different from those of similar looms in advanced countries. At the same time, due to the lack of new chemical fiber raw materials and poor quality indicators, defects are prone to appear in weaving, dyeing and finishing, which also restricts product design and development.

3. Lack of product development center. Many factories mainly process incoming materials and samples, and do not have a department dedicated to developing textiles. As a result, they have poor product development capabilities and can only undertake relatively low-level businesses. The textile benefits are not good and the market prospects are poor.

4. Low production efficiency. Workers in many small factories are not well-skilled and have a low stand rate. Advanced enterprises generally have more than 16 stands per person, and most small enterprises have around 4 stands. It is not uncommon for one person to watch two cars. The management level is low, and the machine cannot be kept in the best condition. The traditional shuttle loom management method is still used to manage the advanced equipment, and the role of the high-end loom cannot be fully utilized.

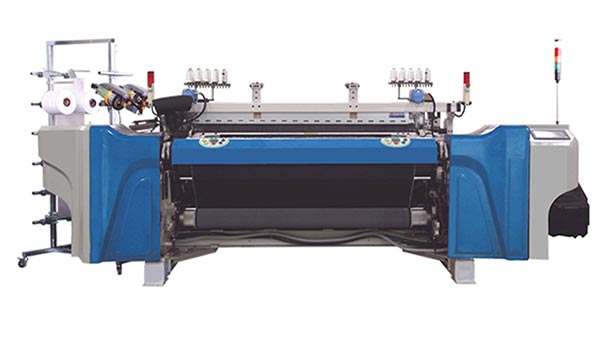

Aiming at the pain points of the textile industry, Suntech has launched the ST-ERL-808-ULTRAFAST808 Ultrafast Start Rapier Loom with 50 years of design experience and technology precipitation, which has the following advantages:

1. High speed and high efficiency: The maximum speed can reach 800 rpm, and the stable speed can reach 550~660 rpm. Intelligent technology improves the textile efficiency and speed, improves the stiffness of the weft warping mechanism, and increases the weft pressing force, even if the operator is skilled and managed The level is limited, and the equipment can still complete most of the difficult tasks, solving the problem of low productivity in most enterprises.

2. Stable performance: The equipment is driven by a motor imported from Spain, heavy special steel and solid beams and bases. The quality is excellent, which ensures the stability of the rapier holder and the rapier tape under high-speed operation, and its wear resistance and use The service life is 5 times that of traditional aluminum alloy guide rails. The instantaneous torque of the motor reaches 3000 Nm, so that the speed ratio speed can be reached immediately after the loom is started, and the motor can run for a long time without being affected by heat.

3. Power saving: Compared with traditional looms, the power consumption of this loom can be saved by 15%-20%.

4. Technical support: Suntech, as an old-brand mechanical intelligent manufacturing company, has a deep technical background and can provide loom technical support and after-sales service to ensure the normal installation and operation of the equipment, save customers installation and commissioning time, and ensure that the equipment matches the product. Let production run normally.

The equipment is widely used, suitable for the weaving of conventional fabrics such as cotton, linen, wool, silk, chemical fibers, and also suitable for the production of special industrial fiber fabrics such as glass fiber, metal fiber, and basalt fiber. It is suitable for all kinds of textile enterprises. Welcome Please inquire for details.