With the deepening of international cooperation, the textile industries of various countries are facing opportunities and challenges. The focus of competition will be the adjustment of product structure, the improvement of product grade and quality. How to speed up the pace of technological progress and increase the proportion of shuttleless looms is a fundamental shortcut to solving the problem of high-grade products. Rapier looms are widely adaptable and cost-effective. They account for the largest proportion of shuttleless looms. The technical level of rapier looms will directly affect the grade and quality of textile products and the development of the textile industry.(try suntech Rapier loom)

International rapier loom technology level

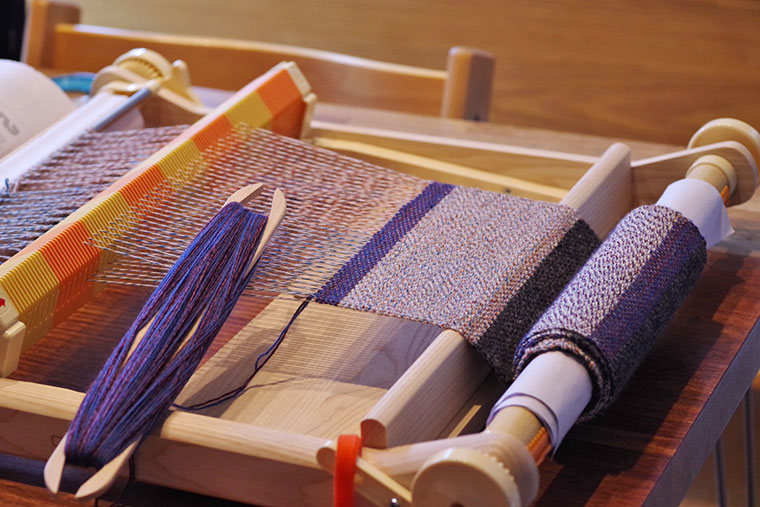

Among the shuttleless looms, the rapier loom is the universal and most reliable loom for weaving small-batch, medium-batch, and colorful fabrics with frequent variety changes. The price is lower than that of projectile looms. In recent years, with the improvement of the weft insertion mechanism, the speed of weft insertion has increased, but the change in acceleration has been relatively gentle. The structure of the sword head that clamps the weft movement can be applied to yarns of different raw materials and structures. There is no need to change the sword head between 0.7tex and 3300tex.

The range of fabrics processed by rapier looms has developed from medium-thick fabrics to light-weight fabrics, from apparel fabrics to decorative and industrial fabrics, from single-layer fabrics to pile and double-layer pile fabrics, and from narrow widths to 4.6m. The breadth of it has developed from low speed to high speed. Nowadays, the highest weft insertion rate of rapier looms has exceeded 1500m/min, and the color selection of weft yarns has developed from a single color to a maximum of 16 colors, which is inferior to other shuttleless looms in terms of variety adaptability.

In recent years, internationally, the highest demonstration speed of the new rapier loom can reach 830 remain, which has a wide range of applications, especially in the application of multi-color weft and multi-warp warp fabrics with large fiber differences. In order to achieve high speed For weaving low-strength warp yarns, there are many types of looms that have eliminated the guide sword crimping device.

In terms of mechatronics applications, the combination of high-performance industrial controllers with CPU as the core and new drive technology, as well as the application of various new sensors on the loom, enable the rapier loom to be automated and intelligent. Mechatronics and informatization have improved the overall level of rapier looms. Since real-time information control of the loom is realized, it provides more data information for equipment monitoring, and the control of the loom is more convenient and the performance of the loom is more superior. The structure is simpler. Rapier looms can choose SQC variety quick-change system, and the main driver of many models is also driven by a variable-speed motor.

In the future, the development of rapier looms will tend to be automated, intelligent, and digitized to achieve efficient operation and management of textiles, and greatly increase output, quality, and production speed.

Overview of Chinese rapier looms

According to incomplete statistics, as of the end of 2020, there are nearly 10 million looms of various types in China, and the rate of shuttleless looms is 24.83%. Weaving industry through industry structure adjustments and system adjustments, the proportion of rapier looms in coastal areas has accounted for more than half of China, and the ability of products to adapt to the market has increased. Many companies have carried out joint ventures, transformations, and equipment upgrades. Partial export.

Chinese rapier loom technology

Since China introduced wide-width rapier looms for weaving blankets in the mid-1970s, it has so far owned nearly 750,000 rapier looms of more than 70 different models from 25 manufacturers in 11 countries and regions. It will continue to be introduced every year in the number of 50,000-0.8 million units, which are widely used in clothing, decorative fabrics, home textiles, neckties, trademarks, and special industrial fabrics.

In recent years, with the improvement of Chinese rapier loom technology, it has been able to independently produce rapier looms on a large scale, and compared with international rapier looms, it has avoided disadvantages and has greater advantages.

China’s rapier looms use microprocessor monitoring, which can monitor and display the operating conditions and various process parameters of the equipment, and combine high-speed electronic dobby, electronic jacquard shedding mechanism, and electronic weft selection mechanism, which can be in operation Quickly and easily change the weave and weft color.

The electronic let-off mechanism can automatically adjust the warp tension under the control of the microcomputer, and keep constant from the full axis to the empty axis; the electronic winding mechanism can be set by the microcomputer, and the weft density can be changed during operation; when the automatic weft finding and weaving device are working Different programs can be set. Under the control of the microprocessor, all the mechanisms, especially the electronic let-off and take-up mechanism, can be synchronized with them, ensuring the most precise weft density and constant warp tension during operation, and minimizing driving marks.

The use of an electronic weft tensioner and an electronic weft feeder can effectively control the tension of the weft yarn throughout the entire process of weft insertion, thereby increasing the speed of the loom. When the rapier loom is equipped with a fold-in device, the woven fabric can be comparable to that of a shuttle loom.

Due to the above-mentioned functional characteristics, China's rapier loom has guaranteed new product development and fabric quality, and the product structure and grade have been significantly improved.

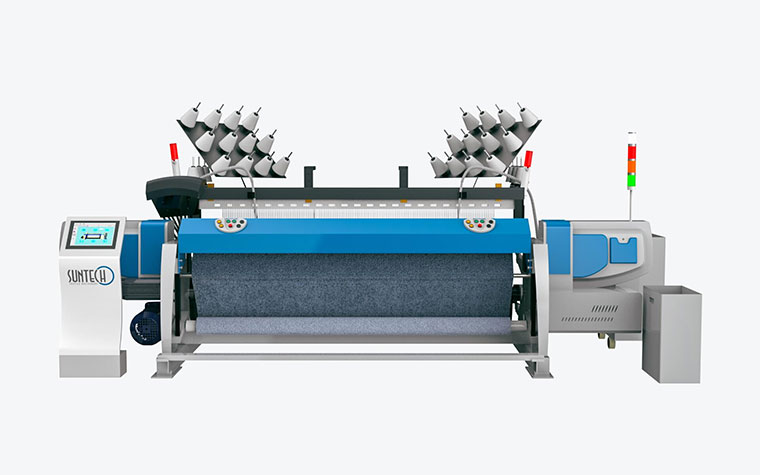

As a well-known intelligent machinery company in China, Suntech specializes in R&D and production of intelligent rapier looms (ST-ERL-808-ULTRAFAST808 Ultrafast Start Rapier Loom) with 50 years of design experience and technology precipitation. In addition to the above functional advantages, it also has the following advantages :

1. High speed and high efficiency: The maximum speed can reach 800 rpm, and the stable speed can reach 550-660 rpm. Intelligent technology is used to improve the textile efficiency and speed, improve the stiffness of the weft warping mechanism, and increase the weft pressing force.

2. Stable performance: The equipment is driven by a motor imported from Spain, heavy special steel, and solid beams and bases. The quality is excellent, which ensures the stability of the rapier holder and the rapier tape under high-speed operation, and its wear resistance and use The service life is 5 times that of traditional aluminum alloy guide rails. The instantaneous torque of the motor reaches 3000 Nm so that the speed ratio speed can be reached immediately after the loom is started, and the motor can run for a long time without being affected by heat.

3. Power saving: Compared with traditional looms, the power consumption of this loom can be saved by 15%-20%.

4. Technical support: Suntech can provide after-sales service such as installation and commissioning, overseas technical support, 12-month warranty, 24-hour customer service, etc. to save customers' installation commissioning, operation, and maintenance costs.

This equipment is widely used, suitable for the weaving of cotton, linen, wool, silk, chemical fiber, and other conventional fabrics, and also suitable for the production of special industrial fiber fabrics such as glass fiber, metal fiber, and basalt fiber. It is suitable for all kinds of textile enterprises. Welcome Please inquire for details.