As a "world factory", China has always been proud of its abundant labor force. Once upon a time, countless foreign companies entered the Chinese market, and cheap labor is also one of the important reasons why foreign companies flocked into the Chinese market.

It is undeniable that in the past few decades, China's sufficient labor force has made a great contribution to economic development. On the other hand, with the continuous improvement of the economic level, China's labor costs have also changed. According to everyone's expectations, labor costs are constantly rising.

The gradual increase in labor costs has always been a "contradiction". From the perspective of the enterprise, it is natural to hope that the lower the cost, the better, but from the perspective of the laborer, the labor cost is "the more expensive the better." This caused a gap between the enterprise and the labor force.

Rising labor costs

From 2000 to 2016, China’s labor force has skyrocketed, and the manufacturing industry’s losses have also become apparent. As for the increase in labor, many experts clearly "stand in line" with companies. Regarding the increase in labor costs, experts say It is not conducive to the development of competition among manufacturing industries.

Along with the artificial rise, the demographic dividend has gradually faded. Although China is still the world's most populous country with a total population of 1.4 billion, China's demographic dividend is obviously not as good as before. And experts explained that it has entered the post-demographic dividend period.

The relationship between labor and population is inseparable. Only when the total population rises can the sufficient labor force be guaranteed. However, now that the demographic dividend is fading and labor costs are rising again, whether the competitive advantage of the manufacturing industry will weaken in the future, many experts have already given the answer.

Experts have a clearer attitude towards the "expensive" of labor. Expensive labor has advantages and disadvantages. For companies, it is obvious that the disadvantages outweigh the advantages. Labor is "expensive" to increase the pressure on enterprises, and China's manufacturing industry is inherently a low-profit industry, and in the past few decades, China's manufacturing industry has been very dependent on labor costs.

Although with the continuous improvement of technology, the manufacturing industry's dependence on labor costs is constantly decreasing, China is still a large manufacturing country, which also means that the impact of labor costs on enterprises is still relatively large.

The most intuitive manifestation of the increase in manufacturing pressure is that many foreign companies have moved away from the Chinese market in the past two years and eventually moved to Vietnam, India and other places. The most important thing is the cheap labor in these countries.

Look at the problem from different angles, and get different answers. Although the increase in labor costs will increase the pressure on the manufacturing industry, it will also promote the transformation of enterprises from low-end manufacturing to high-end manufacturing. Not only can reduce labor, but also increase profits.(trysuntech Loom)

Regarding the artificial "price increase", some people are happy and some are worried. Of course, the majority of employees are happy, but for most low-end manufacturing companies and traditional textile companies, the pressure has increased significantly. However, there is pressure to have motivation. It is time for low-end manufacturing to transform to high-end enterprises. The key to the transformation lies in how to reduce dependence on labor, so as to fundamentally reduce labor costs and improve the ability to resist risks.

In the weaving process, weaving and cloth inspection are the most labor intensive. If mechanized and intelligent equipment can replace labor, it will not only improve production efficiency, but also save labor costs.

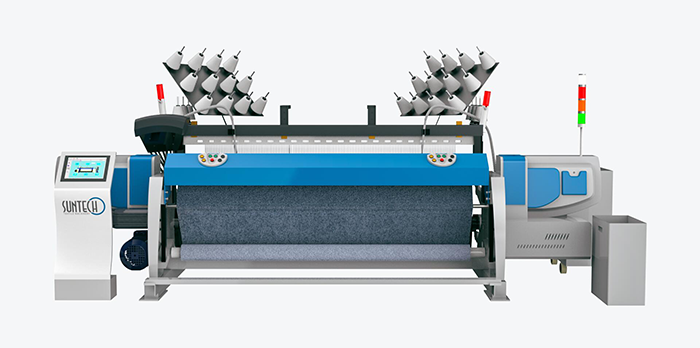

Aiming at the problems of labor shortage, waste of resources, and low production efficiency, Suntech has developed and produced rapier looms with intelligent, automated, and digital applications based on 50 years of design experience and technology precipitation. The operation link is replaced by machinery. At the same time, the intelligent cloth inspection function is perfectly integrated, and the intelligent textile and intelligent cloth inspection are integrated. The machine automatically inspects the finished cloth, which solves the most expensive cloth inspection problem in the finishing process, and the cloth inspection effect is better than Manual cloth inspection, with low error rate, realizes the optimization of textile process and maximum value, reduces labor, greatly reduces labor costs, and improves production efficiency.

Customers who have used Suntech rapier looms are full of praise for this loom, which can be called artificial intelligence in the loom industry. According to statistics, this loom can save 20%-30% labor costs on average and increase 20%-30 %Production efficiency, in addition to automatic cloth inspection, it can also be controlled by PLC, automatic weft search, servo electronic warp let-off, servo electronic winding, so that every step of the textile is intelligent, and the production speed can be greatly improved. Welcome to learn more Inquiry.