There’s all-known that advancements in new technologies bring huge difference to modern manufacture industry. We enjoy the advantages that technology development bring to us but in the same time face the new challenges that comes with development. For example, in the fabric and weaving industry, compared with the past ,today there is a number of weaving shaft with high weight, usually in 1000-2500kgs, it is unable for human to move the shaft car without equipment. So that motorized beam trolley and electric warp beam carriers be created on time. So it is the reason of why motorized beam trolley and electric warp beam carriers becomes so important in today’s weaving industry.

SUNTECH is an internationally enterprise that formally established in 1970S. We always specialize in researching and developing and producing professional textile machinery. We also devote us into the field of weaving machine equipment such as motorized beam trolley,beam stackers,cloth roll trolleys,etc. Today,we will have a brief introduction of one of SUNTECH motorized beam trolley : ST-MBT-04.

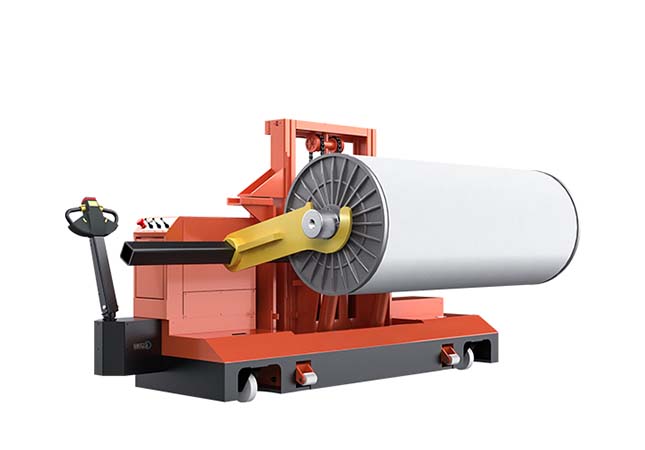

ST-MBT-04

Features

The entire name of ST-MBT-04 is SUNTECH motorized beam trolley, it is designed with AC motor system for easier operating. The max loading capacity of it is up to 2000kgs and the max loading height is up to 2300mm but it is acceptable for us to customized a beam height of your requirement . The gel battery can last 8 hours for the ma working time/day. This equipment helps weaving industry increase 50% working efficiency without any pollution and smoke generated. The characteristic of low noise also make the working environment quiet and clean.

Main Applications

It is mainly be used for inserting in weaving machines, transporting the upper beam and loading of warp beam storage racks or batch storage racks. Also for removing the batches from the winder or for mounting the sectional beams in knitting machines as well as the for handling of non-woven material rolls.

Technical Specifications

1. Gel battery set, its working time is twice than traditional lead acid battery and don’t need balanced charging. Compared with lead acid battery, it is more convenient for long-term storage,it requires-50℃to +50℃ temperature environment and after 1 year storage in a normal temperature environment, it can still reach 90% battery capacity, which saves the maintenance cost.

2. The electric power steering and polyurethane running wheels design, which mounts one after the other in an oscillating manner, leading to low ground contact pressure with high stability. The electric steering system uses motor to control the dive wheels instead of manpower to turn the drive wheels. When it need to adjust the direction of trolley, all the operator need to do is to turn the handle lightly.

3. Telescopic supporting rollers with safety control,ensuring a safe operation.

4. Three motors for lifting and driving, the beam barrel diameter is about 100-40mm, beam flange diameter is 800-1100mm around.

5. AC motor, different from DC motor, it is in a simpler structure design and can working more efficiently than DC motor without generating smoke or pollution, also the maintenance is for free.

SUNTECH Electric Warp Beam Carriers

SUNTECH electric warp beam carrier are all designed technically. All our products in this production line are fully motorized and are all suitable for top/bottom beam transporting & weighting warp beams & inserting in weaving machines. All of them are equipped with motor, which achieves the lifting movement by the motor-driven with automatic quick lift. And we provides a required beam width. SUNTECH is a world-wide company that focus the research direction in fabric make-up machine, material handling equipment production, has the experience for more than 50 years, SUNTECH electric warp beam carriers all featured with high efficiency,low labor cost,convenient operation, guaranteed quality and safety. If you want to have more details of SUNTECH, the first step is calling us !