The textile industry is known as a global industry. Due to development of technology, it is undergoing a great change. Industries must improve the efficiency of the production process, including cutting, weaving and so on, to adapt to the change of the market. SUNTECH beam stacker can help to enhance automation of the process of storage.

Advantages of Automation in Textile Industry

More Production in Less Time

It’s becoming possible to produce more high quality products at a specific time with automation in the textile industry. In the traditional industry, nearly all the work was done by workers who could not work for 24 hours a day. Workers would get tired and exhausted, so they need a break. But automation can never be tiring and it’s possible to work non-stop. As a result, automatic machines help improve efficiency.

Product Quality Enhancement

Using automatic machines, it is possible to produce higher quality and flawless products than before. Workers may make mistakes for different reasons, such as having a cold, not feeling good and so on. But basically these will never happen on automation. So there are fewer mistakes produced by automatic machines, which will greatly improve product quality.

Low Labor Wages

Automation will reduce the number of workers in various stages of production. Therefore, the same work is being done by fewer workers and less time than before, which can help factories reduce labor wages.

Reduce Production Costs

Leaders of company signed a development agreement to obtain an automated machine that handles multiple fabric processing steps, including cutting and sewing the materials. The most important aspect is that it only takes 22 seconds to finish a T-shirt.

Increased Job Security for Workers

It is known that in the textile industry, fabrics are made from yarn that is from fiber. And dyeing and printing can make the fabric more attractive. Each step, especially for the spinning, weaving and dyeing process, might be dangerous to anyone. Thus, automation can make a safe work condition for workers.

Increasing Demand for Skilled Workers

Automation has reduced the number of workers in the textile industry which needed 150-200 workers before. Therefore, on the one hand, with less workers in the industry, it gives them more opportunity to accept technical skills training. On the other hand, with demand for skilled textile workers increasing, more and more workers choose to improve their skills.

Reduce Working Hours for the Same Production

Automatic machine makes it possible for the same tasks to be executed but with less hours. For example, inventions such as Eli Whitney’s cotton gin made it viable to separate the seeds from cotton without utilizing manual labor.

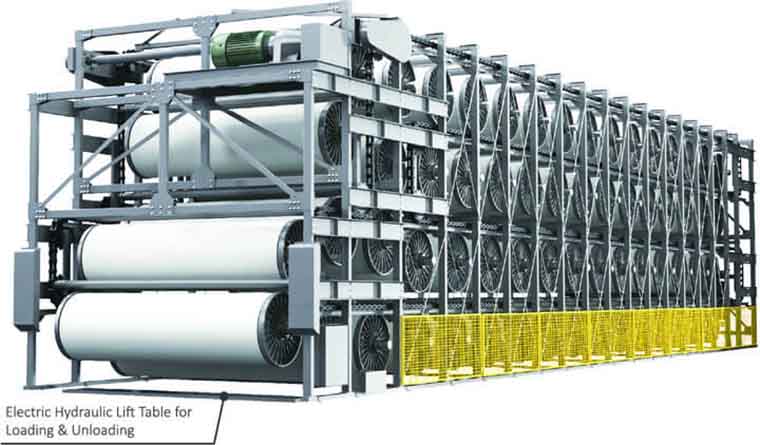

Computerized Warp Beam Storage System

SUNTECH beam stacker, using digital monitoring, automatic classification management and storage of the Warp beam can be accomplished. Hence it helps discover and retrieve the needed Warp beam in a more swift and precise way.

Features

1. Intelligence, reduce labor costs and improve efficiency.

2. Sequential control of machine is enclosed by control panel with PLC.

3. Touch Screen Operation, easy and quick access of data or machine operation through HMI (Touch Panel).

4. Customizable language, different languages are provided.

5. It can be controlled by a mobile phone.

6. ERP system can be connected.

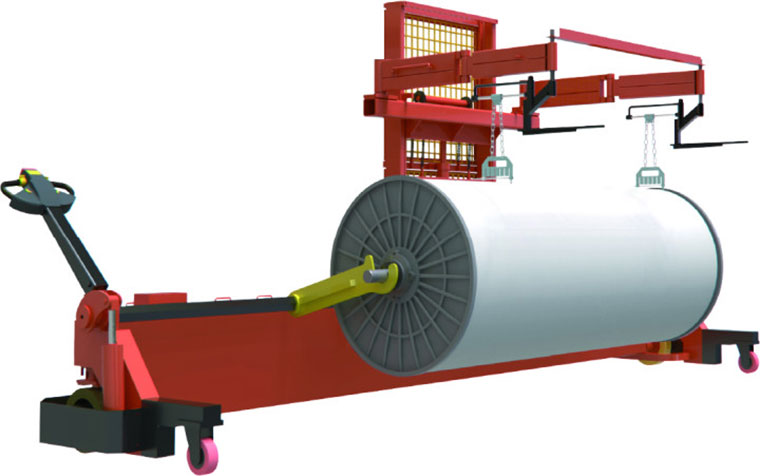

Motorized Warp Beam Lift Trolley with Harness Mounting Device

SUNTEC Motorized warp Beam lift trolley is suitable for Bottom Beam transporting, using harness mounting device and insert in weaving machines.

Warp beams weigh up to 2500kg and an additional loading capacity of 400 kg for the harness.

Features

Meets with European CE standard, certificate is available.

Warranty extension is required.

SUNTECH is a professional international enterprise with decades of experience and research. We are committed to providing customers with excellent products and customized service. Our experienced experts will offer customers timely and efficient combined services in pre-sales consultation, sales, maintenance, and comprehensive after-sales support, giving customers the ultimate and comprehensive service experience. Welcome to visit our website for more information. We are always ready to provide you the best service.