Smart visual inspection system in the fabric inspection is actually the combination of the automatic optical inspection(AOI) and the machine learning algorithms, which offers the textile industry a intelligent and automation inspecting solution in a efficient and accurate way, leading to a perfect fabric quality control, by identifying tiny fabric defects that may missed when manual inspecting, by detecting and recording fabric flaws in a fast speed in the fabric inspection workflow. Smart visual inspection system has been developed in the meantime to such a trustworthy level that totally beats the manual inspection. However, how much important it is for the fabric inspection to use a smart visual inspection system?

Benefits of Smart Visual Inspection System

Fabric quality control is one of the most crucial processes in garment and textile workflow, as this essential precondition, the traditional manual fabric inspection methods seem always slow and unreliable. The smart visual inspection system automates the fabric quality control to improve the process.

1. Improved Accuracy & Efficiency

Smart visual inspection systems use advanced algorithms and image recognition technology to identify defects and inconsistencies in fabric. This results in a higher level of accuracy in detecting defects, reducing the chance of human error.

The use of a smart visual inspection system can significantly reduce the time it takes to inspect fabric. This is because the system can inspect fabric at a much faster rate than a human inspector.

2. Consistency

Smart visual inspection systems can maintain a consistent level of quality in fabric inspection. This is because the system is not subject to the same level of variability that can occur with human inspectors, such as fatigue or distraction.

3. Cost Savings

The use of a smart visual inspection system can result in cost savings over time for the Smart Visual Inspection Systems reduces the need for human inspectors, freeing up resources and reducing labor costs. This can be especially beneficial for companies that handle large volumes of fabric and require fast turnaround times.

4. Data Collection

Smart visual inspection systems can collect and analyze data on fabric defects. This information can be used to identify patterns and trends, which can help to improve the manufacturing process and prevent defects from occurring in the future.

The use of a smart visual inspection system in fabric inspection can improve accuracy, increase efficiency, maintain consistency, result in cost savings, and provide valuable data for process improvement.

Working Principle of Smart Visual Inspection System

The working principle of an AI camera fabric inspection system involves the use of advanced algorithms and computer vision technology to identify defects and inconsistencies in the fabri

l Capture Images: The AI camera fabric inspection system captures high-resolution images of the fabric using cameras or sensors.

l Pre-Processing: The captured images are pre-processed to remove noise, adjust lighting, and enhance contrast to improve the accuracy of defect detection.

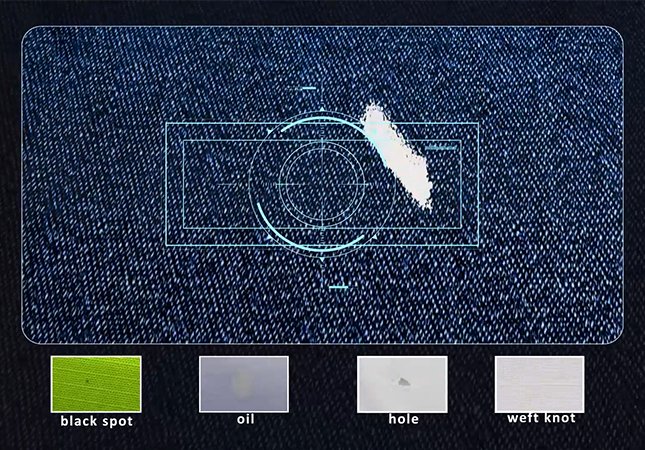

l Defect Detection: Advanced algorithms and computer vision technology are used to analyze the pre-processed images and identify defects in the fabric. This involves comparing the fabric images against pre-defined defect types, shapes, and sizes.

l Defect Classification: Once defects are detected, they are classified into different types such as holes, stains, or weave defects.

l Display and Reporting: The AI camera fabric inspection system displays the location and type of the detected defects on a monitor for review by an operator or system. This information can also be stored and reported for process improvement purposes.

The smart visual inspection system uses artificial intelligence (AI) and machine learning techniques to continuously improve the accuracy and speed of the defect detection process over time.

With the information collected through smart visual inspection system, the fabric defects range and yields can be increased, critical defects prevented and production lines can be stopped before they continuously produce scrap.

Til now, many quality inspection workflows are still manual. Preconceptions over smart visual inspection system’s accuracy or trust in human workers may keep some facilities from automating these areas, but today’s technology offers several advantages.

SUNTECH Smart Visual Inspection System

SUNTECH keeps deploying the textile machinery manufacturing technology with involving a variety of intelligent and automated technologies. SUNTECH’s products and models, especially the ST-Thinkor,by equipping with 1000000+ defects database with AI deep learning, doing its utmost to save fabric inspection time and >95% precision detection, by featuring the automated camera inspection system, ensures 24 Hrs unmanned operation.

Features of ST-Thinkor(ST-Thinkor)

l High Intelligence, 24 Hours 100% Attention

l Reduce dependence on people and ensure stable production

l High Efficient, Speed 60m/min

l Comparing with manual inspection 10-15m/min,4 times increased

l Can replace 3-5 inspector, greatly save the labor cost

l High Precision, Inspection Rate Upto 90%

l Comparing with manual inspection rate, 30% increased

l Convenient Scalability, ERP/SAP Compatible

SUNTECH’s over 50 years experience of the textile machinery manufacturing and performance record of ST-Thinkor and other series of SUNTECH products speak for ourselves, offering the best solution in turn and enable our customers trust and using our products to have a leading edge.

Technology in Smart Visual Inspection System

Smart visual inspection systems are used to automatically inspect and analyze products or materials in real-time, with the help of advanced technologies such as computer vision, machine learning, and artificial intelligence. The following are some technologies commonly used in smart visual inspection systems:

1. Computer Vision

Computer vision is a field of study that focuses on enabling machines to interpret and understand visual data from the world around them. It involves the use of algorithms and mathematical models to analyze images and videos and extract useful information.

2. Machine Learning

Machine learning is a subset of artificial intelligence that involves the development of algorithms and models that can learn from data without being explicitly programmed. In smart visual inspection systems, machine learning is used to train models to recognize defects and anomalies in products or materials.

3. Deep Learning

Deep learning is a subset of machine learning that involves the use of artificial neural networks to model and solve complex problems. In smart visual inspection systems, deep learning is used to analyze images and videos and extract features that can be used to identify defects and anomalies.

4. Edge Computing

Edge computing is a distributed computing paradigm that involves processing data at the edge of the network, close to where the data is generated. In smart visual inspection systems, edge computing is used to perform real-time analysis of visual data, reducing latency and improving system performance.

5. Internet of Things (IoT)

The Internet of Things (IoT) is a network of interconnected devices that can communicate and exchange data. In smart visual inspection systems, IoT is used to connect cameras, sensors, and other devices to a central processing unit, allowing for real-time monitoring and analysis of visual data.

6. Cloud Computing

Cloud computing involves the use of remote servers and computing resources to store and process data. In smart visual inspection systems, cloud computing is used to store and analyze large amounts of visual data, allowing for more comprehensive analysis and reporting.

7. Augmented Reality (AR)

Augmented Reality (AR) is a technology that superimposes digital information onto the physical world. In smart visual inspection systems, AR can be used to provide workers with real-time visual feedback and guidance, improving the efficiency and accuracy of inspection processes.

Conclusion

Smart visual inspection system is a game-changing technology in fabric inspection field that offers unprecedented accuracy, efficiency, and cost-effectiveness in the fabric inspection process. By leveraging the power of advanced technologies such as AI, machine learning, and computer vision, this system is capable of detecting defects and anomalies with an incredible level of precision and speed.

With its ability to inspect large volumes of fabrics in real-time, the smart visual inspection system is a critical tool for ensuring fabric quality in the textile industry, also in other industries such as manufacturing, automotive, pharmaceuticals, and food processing.

Overall, the smart visual inspection system is a powerful example of how technology can transform traditional industrial processes, and it is poised to play a key role in shaping the future of manufacturing and production. As SUNTECH continue to embrace technological advancements, we can expect to develop more innovative solutions like the smart visual inspection system emerge, leading to greater efficiency, accuracy, and sustainability in the textile industrial operations. SUNTECH never stops running in the innovation,contact us now and check on our official website!

https://www.suntech-machine.com/

https://www.suntech-machine.com/product/st-aci-automatic-camera-inspection-system-152.html