A recent study conducted by the Waste and Resources Action Programme has unveiled a startling statistic: up to 15% of knitted fabric is wasted during production due to defects like snags and needle lines. This issue not only incurs substantial financial losses for manufacturers but also exacts a toll on the environment. However, a new horizon emerges with the integration of deep learning algorithms into visual inspection technology, replicating human visual scrutiny within a computerized system.

The union of automated visual inspection and deep learning algorithms represents a groundbreaking advance. This synergy empowers the system to discern various components, irregularities, and patterns akin to human perception. This technology leap is particularly evident in the identification of texture, weaving inconsistencies, stitching flaws, and color mismatches.

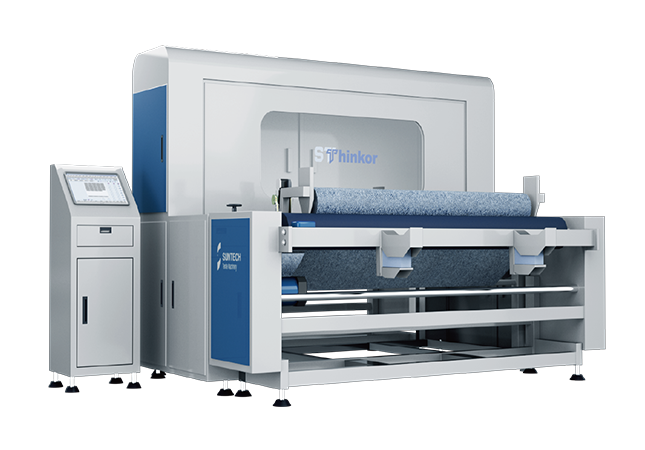

One exemplar of this technological stride is the AI Automated Visual Inspection System, ST-Thinkor, designed and pioneered by SUNTECH Textile Machinery. This innovation has found application across a diverse spectrum of industries including fabric production, garment manufacturing, home textiles, electronics, industrial glass fiber production, automotive interiors, airbag manufacturing, and non-woven fabric production, showcasing its remarkable versatility. Notably, its adaptability spans different machinery types, from traditional fabric looms to cutting-edge glass fiber looms, fabric inspection machines, laminators, stenter machines, shrinkage machines, and non-woven machines. This versatility extends to various fabric categories, encompassing denim, wool, chemical fibers, cotton, leather, automotive interiors, glass fibers, airbags, and non-woven fabrics.

At its core, the ST-Thinkor AI Automated Visual Inspection System boasts a comprehensive array of advanced technologies. These capabilities enable it to accurately identify an extensive array of textile defects, ranging from broken threads and fillings to knots, holes, dirt, fuzziness, weft shrinkage, and more. This state-of-the-art solution ensures unparalleled production quality and heightened customer satisfaction through its unparalleled ability to detect any form of irregularity.

The escalating demand for automation brings a host of advantages such as enhanced productivity, reduced waiting times, and improved occupational safety. Automated storage, weighing, and dispensing systems further minimize worker exposure to chemicals and dyes, thereby mitigating risks. Additionally, digital storage systems efficiently manage stock levels, guaranteeing timely and precise ordering when required.

The emphasis lies not merely in identifying defects and eliminating subpar fabrics, but in elevating the quality of knitted textiles to unprecedented heights. The data collected during today's production cycle informs improvements for tomorrow, creating a cycle of continuous enhancement.

As the industry evolves towards Industry 4.0, textile manufacturers face a crucial crossroads. Those who adapt stand to gain substantial benefits and outperform their competitors, while those who do not risk being left behind. The era beckons textile manufacturers to embrace digital transformation and envision a progressive future.

SUNTECH Textile Machinery emerges as a beacon in this paradigm shift. Renowned for integrating innovation with optimization, the company has solidified its position as a leader in the textile industry. Their portfolio spans from advanced fabric inspection machines and automated packaging lines to high-speed weaving machines, equipping manufacturers with the tools to boost productivity, trim costs, and excel in today's dynamic marketplace. The full potential of SUNTECH Textile Machinery awaits, offering manufacturers the means to propel their textile production into an era of excellence.