From a global perspective, Europe and the United States are the world’s largest wet wipes consumer market, with consumption accounting for more than 70%. According to the analysis of the domestic market demand environment, it is affected by aging, the second-child policy, and the increase in consumer consumption and healthy consumption concepts. The market demand for wet wipes in China is huge.

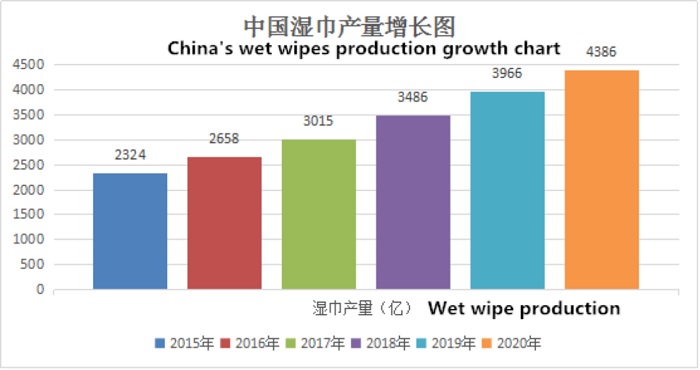

According to market research, from 2015 to 2019, the production of wet wipes in China showed a steady increase. The output in 2015 was about 232.4 billion, and the increase in 2019 was about 396.6 billion. In 2020, it will reach about 438.6 billion. According to the calculation that the spunlace non-woven fabric can produce about 670,000 wet wipes, the production of China's wet wipes in 2020 will require 658,000 tons of spunlace non-woven fabric.(Click to share to LinkedIn)

At present, the demand for non-woven fabrics has maintained rapid growth and is expected to continue to grow until 2025. Due to the good market prospects and advantages of non-woven fabrics, in recent years, it has become the fastest growing field in the non-manufacturing industry. China's non-woven fabric production lines are developing rapidly, of which Jiangsu and Zhejiang provinces are the most prominent. After the global new crown pneumonia crisis, the non-woven fabric industry is not only unaffected, but extremely hot. Among them, spunlace non-woven fabrics and spunbond non-woven fabrics have the largest demand.(Click to share to Facebook)

In 2020, when the covid-19 epidemic broke out, intensive care, neonatal ICU, hemodialysis machine, ventilator, postoperative operating table, instrument equipment and other surfaces need to be wiped and disinfected with disinfection wipes. The demand for disinfection wipes increases, leading to spunlace non-woven fabrics. The demand has increased, and the increase in demand for masks has led to a large increase in the demand for spunbond non-woven fabrics.(Suntech Spunlace non-woven fabric)

What is the difference between spunbond nonwoven fabric and spunlace nonwoven fabric?

Comparison of Spunlace Nonwoven Fabric and Spunbond Nonwoven Fabric

|

|

Spunlace non-woven fabric |

Spunbond non-woven fabric |

|

Comparison of construction principles |

Spunlace non-woven fabric is also called "spunlace fabric". The concept of "jet-spun net cloth" comes from the mechanical needle punching process. The so-called "jet spun web" is to use high-pressure water to pierce the fiber web to make the fibers entangle with each other, so that the loose fiber web from the original spunlace non-woven fabric has a certain strength and complete structure. |

Spunbond non-woven fabric is a method in which the polymer is extruded and stretched to form continuous filaments, the filaments are laid into a web, and the web is bonded, thermally bonded, chemically bonded or mechanically reinforced by itself. Turn the web into a non-woven fabric. |

|

Application comparison |

1. Medical: disposable surgical gowns, surgical drapes, operating table cloths, surgical aprons, etc.; wound dressing materials, bandages, gauze, band-aids, etc.; |

Polypropylene, polyester (long fiber, short fiber), non-woven bags, non-woven packaging, etc., are easy to identify because the nip point of spunbond non-woven fabric is diamond-shaped. |

What is spunlace nonwoven?

Spunlace non-woven fabric is a new generation of environmentally friendly materials. It is water-repellent, breathable, flexible, non-combustible, non-toxic and non-irritating, rich in color, high strength, good high temperature resistance (can be used for a long time in an environment of 150 ℃), resistant Aging, UV resistance, high elongation, good stability and air permeability, corrosion resistance, sound insulation, mothproof, non-toxic and other characteristics, the main application areas include wet wipes, facial masks, etc., wet wipes are the largest application field in the medical and health materials industry. It accounts for about 70% of the total demand for spunlace nonwovens.

In addition to wet wipes, medical curtains, surgical gowns, surgical drapes, medical dressing materials, wound dressings, medical gauze and other medical and sanitary products, diapers, wet wipes, facial masks and other disposable products are also spunlaced. Non-woven fabric is one of the raw materials.

Process flow of spunlace non-woven fabric

Fiber metering and mixing-opening and removing impurities-mechanical messy carding into a web-fiber web pre-wetting-water needle entanglement-surface treatment-drying-coiling-inspection-packaging and storage

The spunlace device uses high-speed and high-pressure water jets to spray the fiber web to rearrange and entangle the fibers in the fiber web to become a non-woven fabric with a complete structure and certain strength and other properties. The physical properties of this kind of spunlace non-woven bags are different from common needle-punched non-woven fabrics. Both in terms of hand feel and superfine fiber non-woven fabric properties, it is the only non-woven fabric that can make its final product similar to textiles.

Advantages of spunlace

1. There is no extrusion of the fiber web in the spunlace process, which improves the bulkiness of the final product;

2. No resin or adhesive is used, thus maintaining the inherent softness of the fiber web;

3. The high integrity of the product prevents the product from being fluffy;

4. The fiber web has high mechanical strength, which can reach 80%-90% of textile strength;

5. The fiber web can be mixed with any variety of fibers.

6. It is particularly worth mentioning that the spunlace web can be compounded with any base fabric to make a composite product.

7. Products with various functions can be produced according to different purposes.

Advantages of spunlace non-woven fabric

1. Soft and good drape;

2. Good strength;

3. It has high hygroscopicity and fast wetness;

4. Low fluffing;

5. Washable;

6. No chemical additives;

7. The appearance is similar to textiles.

Due to the advantages of spunlace non-woven fabrics, it has become an area with the fastest technological progress in the non-manufacturing sector in recent years. The development direction of non-woven fabrics is to replace textiles and knitwear. Spunlace fabrics have become the most potential field for competition with the textile market due to their most textile-like characteristics, excellent physical properties, and high quality and low price.

In order to meet the production needs of spunlace nonwovens, Zhejiang Suntech Machinery Co., Ltd. specializes in providing intelligent and innovative spunlace nonwovens with 46 years of manufacturing equipment production experience and technology precipitation and the standards of "precision and intelligent manufacturing". And equipped with perfect after-sales service, welcome to detail.