Generally speaking, automation is defined as the use of equipment and machinery to help make production easier and more efficient. Textile manufacturing is mechanically based. Different types of instruments and machines are used for production and testing in the textile industry. Automation brings convenience to textile production. The biggest benefit of automation is labor savings and efficiency gains.

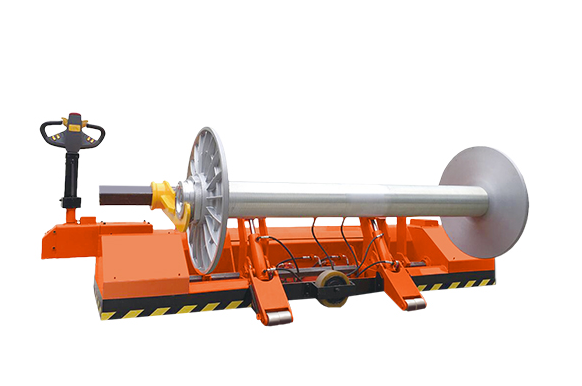

The working process or the whole weaving including winding, warping, sizing, drawing-in, weaving, dyeing and finishing,etc. During these process, the warp beam and weaving beam will be transported back and forth,and will be loaded and unloaded frequently. If so, motorized beam trolley plays an important role during the process.

Warping is the process of winding a certain number of warp yarns in parallel on the warp beam or weaving shaft according to the specified length and width. Warp yarns that have been warped are used for sizing and threading. Warping requires that the tension of each warp yarn is equal, evenly distributed on the warp beam or weaving shaft, and the arrangement of colored yarns conforms to the process regulations. During this process, it will need empty beam trolley to transport the warp beam to the warping machine for warping process. After warping,the empty warp beam will be fulled with yarn. Then it will need a beam trolley to transport the full beam to the sizing machine for sizing process.

Sizing is the process of applying sizing to warp yarns to improve their weaveability. Weavability refers to the ability of warp yarn to withstand repeated friction, stretching, bending, etc. on the loom without causing a lot of fluff or even breakage. The unsized single yarn fibers are not tightly attached to each other, and the surface hairiness is more, so it is difficult to weave. After sizing, a part of the sizing liquid penetrates between the fibers, and the other part adheres to the surface of the warp yarn. The sizing based on the penetration of the sizing between fibers is called permeable sizing, and the sizing based on the sizing sticking to the surface of the warp yarn is called covering sizing. During this process,beam transport trolley can still be used for empty and full beam transportation.

After sizing,the next process will be weaving. Weaving is to make the warp and weft yarns show specific patterns according to certain rules according to the weaving design organization chart provided by the fabric designer. The movement of the warp yarn is completed by the up and down movement of the brown frame, and the left and right movement of the weft yarn makes it have a certain organizational structure and form a specific pattern. During this process,it will need warp beam lift trolley to lift the warp beam to the weaving machine,and after weaving,it need a big batch fabric roll transport trolley to move the fabric roll to the finishing process.

SUNTECH can provide different kinds of motorized warp beam trolley for weaving factory,which brings a lot of convenience for weaving production.

SUNTECH,as a 50 years textile machinery manufacturer,can provide kinds of beam trolley for weaving factory,like warp beam transport trolley,warp beam lift trolley,fabric roll doffing trolley etc. SUNTECH produce European standard beam trolley which has following features:

1. We use AC motor instead of DC motor,which is simple and free of maintenance.

2. We use GEL battery instead of Lead Acid battery,which is free of maintenance and have longer service life.

3. Electric power steering system,which is much easier for operation.

4. CE certificate can be provided