In response to the “mask shortage” during the epidemic, under the vigorous promotion of the Beijing Municipal Government, the Beijing University of Chemical Technology team and the manufacturer proposed an emergency R&D and industrialization project for core materials of reusable civilian masks, using original materials based on free radical controllable degradation. Grade hybrid reaction technology, through a large number of formula and process tests and test characterization, we have developed a long-term static electricity retention, long-lasting antibacterial, anti-aging melt-blown polypropylene material, which ensures that the mask can be reused and the protective ability still meets the requirements after long-term placement Functional requirements.

At the same time, Beijing University of chemical technology, together with 18 experts from 12 units, revised and released the group standard of reusable civil masks, which solved the problem that there is no standard for the reuse of masks at present, provided support for promoting and standardizing the research and development and industry of civil protective masks, and made contributions to human anti COVID-19 situation and won praise.

Why research and development of reusable civil mask materials? It is difficult to improve the production capacity of the key material and filter fiber cloth of the mask in the short term, resulting in the shortage of mask supply. If the melt blown fabric can be reused, the mask production efficiency will be greatly improved.

What's so important about meltblown? Polypropylene is the main raw material of meltblown cloth, and the fiber diameter can reach 1-5 microns. The Microfiber with unique capillary structure can increase the number and surface area of fibers per unit area, so that the meltblown cloth has good filtration, shielding, thermal insulation and oil absorption, which is the key to prevent bacteria.

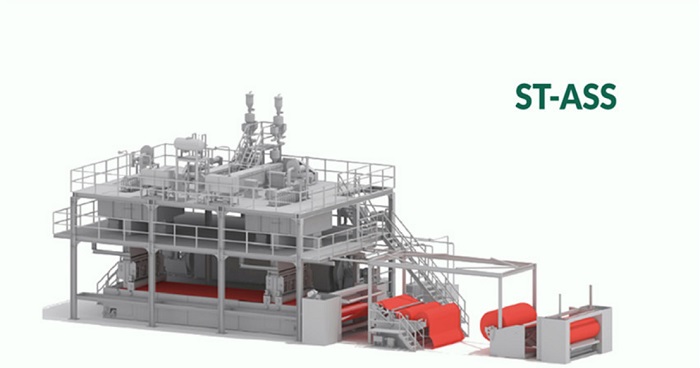

The production of meltblown cloth depends on the cover material and meltblown equipment. Where should I buy these? In order to alleviate the pressure of international COVID-19 situation, Suntech concentrates its core technical resources and R & D strength to design and manufacture high-quality and high-efficiency equipment such as melt blown machine ST-AMB, spinning melt non-woven machine ST-SMS, spunbonded non-woven machine ST-ASS, and also provides mask materials.

1. Melt blown equipment

ST-AMB, ST-SMS and ST-ASS are all made of Japanese advanced technology. They are made of German demage CNC machining center and Italy FIDIA gantry five axis high-speed milling machine with fluid polishing, touch screen PLC control, whole process digital chemical process monitoring, perfect after-sales service and warranty period up to 13 months.

(ST-AMB melt blown machine,Click to contact)

The diameter of spinneret of melt blown machine ST-AMB and spinning melt non-woven machine ST-SMS can reach 0.25 mm, the diameter of spinneret of stress ST-ASS spunbonded nonwoven machine can reach 0.45 mm, and the air drawing can be 1-4 μM.

(ST-SMS spinning melt non-woven machine,Click to contact)

ST-SMS of spinning and melting non-woven fabric machine adopts electrostatic electret treatment, and the produced melt blown cloth can effectively absorb and lock bacteria. ST-ASS spunbonded nonwoven machine can produce spunbonded nonwoven suitable for 3ply, N95, FFP2, ffp3 and other masks.

(ST-ASS spunbonded nonwoven machine,Click to contact)

2. Mask material

Suntech mask material has Intertek, TUV, SGS, gttc and other certificates. Some customers have made masks with Suntech's mask machine and mask materials and passed the local inspection. The price of Suntech's mask material is relatively cheap and its cost performance is super high.

Suntech has its own 22 melt blown production line, which can ship 26 tons per day with short delivery time. It can meet the production requirements of I / II / IIR type face mask, 1 / 2 / 3 class mask, kn95 / N95, ffp1 / FFP2 / ffp3 masks. The material specification, color and weight can be customized to meet the needs of customers in an all-round way.

As one of the leading design and manufacturers of textile machinery, Zhejiang Suntech Machinery Co., Ltd. has more than 4500 customers and 10000 machine installation cases in the world. It not only has rich experience in customizing mask equipment and mask materials, but also has perfect after-sales service. It provides overseas engineers with technical support and relevant guidance. It has a good reputation and high customer return rate.