The recently concluded COP 28 in Dubai marked a crucial milestone in the global effort to combat climate change. As nations grapple with the urgency of achieving net-zero emissions, it is imperative to explore diverse sectors for sustainable solutions. Among these, the textile industry emerges as a potent force with the potential to significantly contribute to the net-zero goal.

Globally, the textile industry generates 92 million tonnes of waste every year, with less than 1% of textiles recycled into new products.

Issues

The manufacture of textiles uses large amounts of natural resources, mainly petrochemical synthetic materials, and produces greenhouse gases that contribute to global warming. According to the United Nations, the industry accounts for 8-10% of global emissions, more than the aviation and shipping industries combined.

It is noteworthy that global warming is the main cause of extreme weather in South America in November this year, with temperatures soaring above 40°C in parts of Brazil, Paraguay, and Argentina. Global warming is also to blame for Storm Babette, which devastated parts of eastern Scotland in October, and the summer fires in Greece. The textile industry must adopt new strategies to offset the negative effects of fast fashion, extend the service life of textiles, reduce their impact on the environment, and help protect our planet.

Time to Change

The industry needs to make massive systemic changes to meet the goals of the Paris Agreement on Climate Change to limit global warming to 1.5°C (above pre-industrial levels). Textile industry leaders must work together to develop, share, and scale new processes to spark this change.

Employing innovative technologies such as robotics, IoE, and artificial intelligence will overcome textile circularity barriers and support the transition to a circular economy.

Technology helps the textile cycle and supports the textile industry’s transition to a circular economy achieving net zero in the textile industry goes beyond materials and processes; it involves fostering transparency throughout the entire supply chain. Ethical sourcing of materials, fair labor practices, and responsible waste management are integral components of a sustainable and net-zero-oriented textile industry. Consumers increasingly demand transparency and ethical practices, making businesses need to adopt responsible measures in their operations.

The integration of green innovations and technology is pivotal in revolutionizing the textile industry.

The development of eco-friendly dyes, packing methods, and IoE techniques not only enhances efficiency but also minimizes the environmental impact. These innovations can lead to reduced water consumption, chemical usage, and overall energy requirements, contributing to a more sustainable and responsible textile manufacturing process.

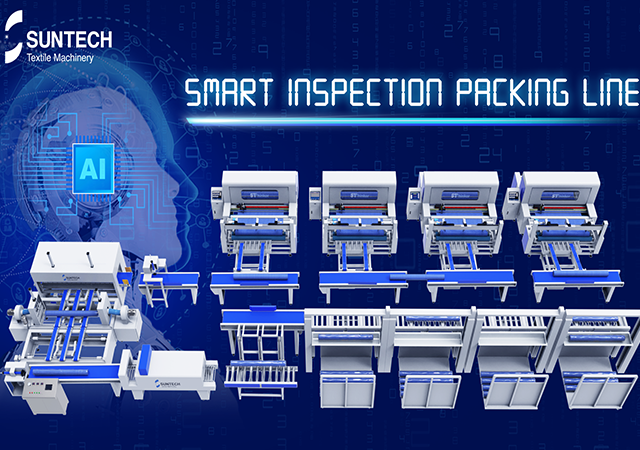

SUNTECH Automatic Packaging Machine - ST-ARPM

SUNTECH automatic packaging machine offers a range of impressive features that enhance efficiency and productivity in the textile industry. With a maximum capacity of 7 rolls per minute, this advanced system streamlines the packing process and optimizes output.

One of the standout features of this packing line is its smart classification capability. It can intelligently categorize packing rolls, eliminating the need for manual sorting, and the automatic packaging machine can be connected to the ST-Thinkor for an accurate fabric roll inspection and quality control before packing and labeling, which saves time and reduces defects rate, ensuring accurate and precise packing every time. ST-ARPM achieves this level of automation with minimal human intervention, requiring only one operator to oversee the entire process.

To cater to the specific requirements of different textile products and manufacturers, the automatic packaging machine offers customization options. This means that the packing line can be tailored to accommodate various sizes, shapes, and types of fabric rolls. Whether it's delicate silk or heavy-duty industrial textiles, this packing line can handle the packing process seamlessly.

Furthermore, the automatic packaging machine incorporates sampling and taping functions. It automatically takes representative samples from each roll for quality control purposes, ensuring that the entire batch meets the desired standards. Additionally, the system applies tape securely to the rolls, preventing any unwinding or damage during transit or storage.

Mapping and labeling are also integrated into the automatic packaging machine. With advanced mapping capabilities, the system records and tracks the exact location of each fabric roll, enabling efficient inventory management and retrieval. Moreover, the automated labeling feature accurately tags each roll with essential information such as product details, batch numbers, and barcodes, facilitating easy identification and tracking throughout the supply chain.

The packing process itself is carried out flawlessly by the system. The fabric rolls are neatly and tightly packed using the most suitable packing method, ensuring they are secure and protected during transportation. SUNTECH Automatic Fabric Roll Packing Machine can adapt to different packing styles and configurations, accommodating various packaging materials and requirements.

ST-ARPM includes a sorting function, allowing the rolls to be organized according to specific criteria such as size, color, or destination. This simplifies the logistics process, enabling faster and more efficient distribution.

SUNTECH automatic packaging machine maximizes productivity with its high capacity and intelligent features. It enables one operator to oversee the entire packing process, thanks to its smart classification system.