The search for agility in the packaging of articles in the processing phase is still very common. This is because many businesses still do not understand the importance of investing in textile technology and smart solutions.

In this context, we summarized the main effects that the lack of optimization of this step can cause to your industry. And, at the end, we present the main tip to ensure greater speed and better results in this process.

What are the impacts of the lack of agility in the packaging of articles in the processing phase?

The packaging stage of articles in the processing phase is still a very recurrent problem in the sector. This is often due to the manual process that can lead to human errors.

Problems with packaging, right at the beginning of the production chain, can generate countless negative impacts on the textile industry. Such as, poor quality packaging, affecting the protection of the rolls. This leads to commercial consequences. Not to mention that these adversities considerably increase the waste of materials. After all, the amount of problems can cause loss of raw material and even affect the rolls themselves.

Therefore, the lack of agility in this process is usually linked to two main factors: manual operation and obsolete machines.

And the lack of outdated equipment can also cause large losses in terms of maintenance costs. After all, the older the machine, the greater the need for care. This can lead to more downtime and unnecessary expenses.

In summary, the lack of agility in the packaging stage of articles in the textile processing stage causes increased costs, waste of time and material, and also affects the competitiveness of your company.

How to improve the processing phase?

It is fundamental to invest in tools capable of solving all the problems of the processing phase. The important thing here is to contribute to productivity, increased profit and reduced waste.

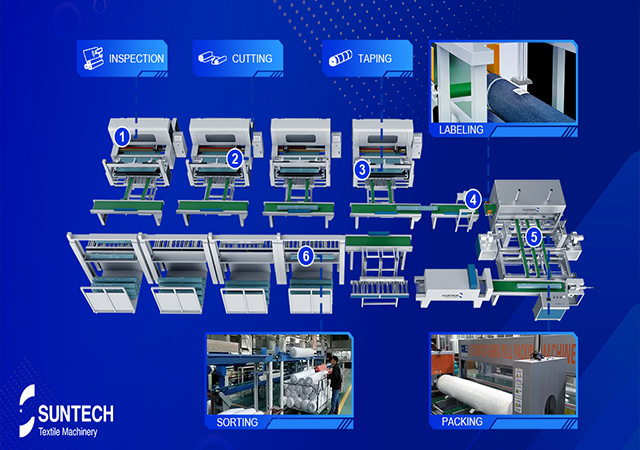

SUNTECH Automatic Packing Machine overcomes the drawbacks of manual fabric inspection, integrating fabric inspection and packaging into a single automated process, which is more convenient and offers many advantages, including:

1.Fully automated. SUNTECH Textile Machinery's fabric inspection machine can detect fabric defects online or offline, determine the location of defects, classify and score defects based on their size, harmfulness, and impact, issue alerts or take measures such as stopping the machine or cutting fabric in the case of severe defects.

Applicable to all kinds of fabrics. SUNTECH Textile Machinery's fabric inspection machine can detect commonly used basic and variant fabrics, including cotton, linen, silk, wool, synthetic and blended yarn fabrics.

2.High pass rate. SUNTECH fabric inspection machines has a significantly higher production rate than manual fabric inspection, even exceeding it several times. The accuracy of automated fabric defect detection exceeds 95%, which is much higher than that of manual fabric inspection, and the miss rate and misjudgment rate are less than 5%, which is much lower than that of manual inspection.

3.Fast and adjustable speed. SUNTECH automatic fabric inspection production speed can generally reach over 120m/min, and can even reach up to 300m/min. The detection speed can be adjusted according to the needs, and the actual inspection speed depends on the fabric width and the type and severity of defects.

4.Automatic length calculation and review. SUNTECH fabric inspection machine is equipped with a length calculation device and can also review the length of seams. Traditional manual fabric inspection requires visual inspection of the fabric surface for defects such as yarn defects, weaving defects, stains, or color differences, and if defects are found, they must be marked immediately at the edge of the fabric for repair or removal. SUNTECH Textile Machinery's fabric inspection machine eliminates this trouble.