Fabric cutting machine/cloth cutting machine is a cutting equipment widely used in textile, leather, rubber, carpet and other industries. At present, the fabric cutting machine used in the market has problems such as poor processing accuracy, low production capacity and low degree of automation. The machining accuracy, production efficiency and operation stability of equipment are closely related to product quality and corporate benefits. It can be said that equipment renovation is the eternal theme of corporate development. In order to make the equipment operate safely and efficiently within a limited service life and maximize the production efficiency of the enterprise, in order to manufacture more products that meet the process requirements, whether the technical performance and processing capacity of the equipment are suitable for production is necessary. Appears to be extremely critical.

In the current high-tech society, more and more customers pay more and more attention to the efficiency of cutting fabric. SUNTECH currently adopts the new plc technology to upgrade the fabric cutting machine and its control system to realize the automation of the fabric cutting machine, so as to improve the processing accuracy and production efficiency of the fabric cutting machine and solve the problems existing in the production process.

Now SUNTECH could provide automatic fabric cutting machine, model st-ascm suitable for batch cutting.

How ST-ASCM can support high efficient and precise cutting work?

1. PLC CONTROL

ST-ASCM is equipped with high-quality PLC, which can run stably. You only need to set the cutting length, width and speed at the beginning, this machine can make accurate and automatic fast cutting according to these data, with small error and fast speed. A lot of cutting time could be saved.

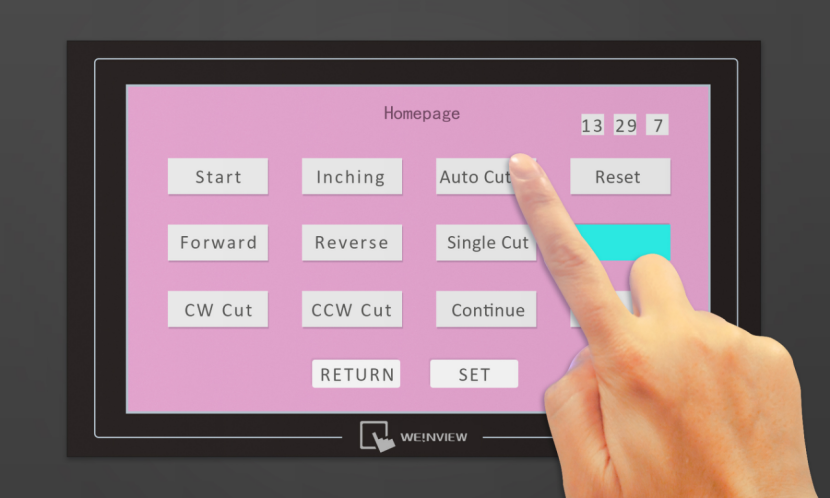

2. TOUCHING SCREEN OPERATION

Equipped with The agile touch screen HMI, the operator can easily set and modify parameters without worrying about operation problems, and has received unanimous praise from customers.

3.EXTRA LONG LIFT CUTTING BLADE

There is no double that the most important part of a fabric cutting machine is its the cutting blade, cutting blade is the core technology of this type machine. In order to improve the working life of the machine, SUNTECH uses HRC63-65 Japanese imported alloy steel, which can be cut 200,000 times. It has 5 times longer life than normal cutting blade.

What's more, SUNTECH can provide 24 months warranty period for the blade and a 12-month warranty period for the complete machine. Within the warranty period, SUNTECH will provide free random accessories due to damage to the accessories caused by the quality of the machine.

4. HIGH-TECH RED LASER

Although the whole machine is controlled by a high-precision PLC, SUNTEH is equipped with a high-tech red laser so that the operator can see the cutting situation more clearly when cutting. Before cutting, the operator can clearly see the cutting position without putting his hand into the cutting position, which ensures the safety of the operator.

5.SAFETY

For a factory, the safety of operators needs to be the first priority. Therefore, SUNTECH's automatic fabric cutting machine is equipped with four pcs of hand protection safety light curtains. When any goods or hands blocks the sensor, fabric cutting machine will stop automatically.

By the way, SUNTECH automatic fabric cutting machine, model ST-ASCM comply with the essential health and safety requirements of the Directive 2006/42/EC. And comply with EN60204-1:2018 and low voltage directive 2014/35/EU.

SUNTECH has 50 years experience in textile machinery manufacturing and now has different type fabric cutting machines for different requirement. If you have any requirement on the fabric sample cutting machine, feel free to contact us. SUNTECH will offer the most suitable machine for you.