An automatic packaging machine typically operates through a series of steps to efficiently and effectively wrap fabric rolls for transportation and storage, here is a general overview of how an automatic packaging machine works.

1. Fabric Roll Loading

Fabric rolls are loaded onto the machine's feeding mechanism, which can be a conveyor or a series of rollers. The rolls are positioned in the desired orientation for wrapping, with the fabric end aligned properly.

2. Wrapping Material Dispensing

The machine dispenses a roll of wrapping material, which can be a plastic film, shrink wrap, or other suitable materials, from a roll or a reel.

3. Wrapping Process Initiation

The machine starts the wrapping process, where the wrapping material is pulled around the fabric roll, typically using rotating rollers or arms, while the fabric roll rotates to ensure even wrapping.

4. Wrapping Material Sealing and Cutting

Once the wrapping material has been fully wrapped around the fabric roll, the machine seals the edges of the material together, typically using heat or adhesive, to secure the wrap. The excess material is then cut, leaving a neatly wrapped fabric roll.

5. Optional Additional Features

Depending on the specific design and features of the machine, additional functionalities may be included, such as label application, stretch film tension control, or printing of labels or barcodes for identification and tracking purposes.

6. Fabric Roll Unloading

The wrapped fabric roll is then released from the machine's feeding mechanism, and it can be manually or automatically unloaded from the machine for transportation or storage.

7. Control and Monitoring

Throughout the wrapping process, the machine's control system monitors and controls various parameters, such as wrapping tension, material dispensing, sealing, and cutting, to ensure consistent and reliable wrapping quality.

Automated packaging machines revolutionize the way fabric rolls are prepared for storage and transportation. Let's delve deeper into the benefits of this technology:

Enhanced Efficiency: By streamlining the packaging process, automation significantly reduces the time required to package items. This time-saving translates to increased productivity and potential cost savings for businesses.

Reduced Waste: Automation brings precision to material usage, resulting in less waste compared to manual packaging methods. This reduction in waste contributes to both environmental sustainability and economical resource management.

Elevated Productivity: Rapid and consistent packaging leads to higher output in a shorter span of time. Businesses can meet demand more effectively, enhancing their overall productivity and market competitiveness.

Product Protection: Automated machines ensure a secure and uniform wrapping process. This reduces the risk of product damage or contamination during packaging, maintaining product quality and customer satisfaction.

Customization: The adaptability of automated fabric packaging machines allows businesses to tailor the process to their specific needs. This flexibility enhances versatility in handling various types of fabric rolls and packaging requirements.

Cost Savings: Automation minimizes the need for manual labor, leading to reduced labor costs. Additionally, precise material dispensing and efficient sealing contribute to lower material expenses over time.

Environmental Sustainability: Automated packaging machines optimize material usage and reduce waste. This aligns with eco-friendly practices, making a positive impact on the environment by reducing packaging-related waste.

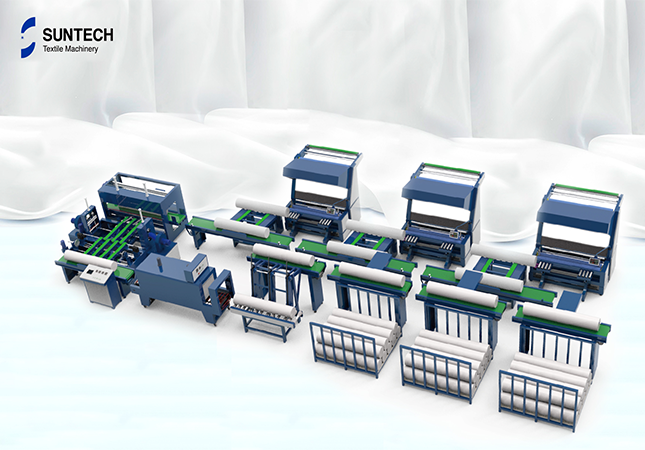

Features of SUNTECH ST-ARPM (Automatic Packaging Machine)

Vacuum & Automatic Packing: This feature amalgamates vacuum technology with automation, ensuring a tightly packed and secure fabric roll.

European CE Standard Certified: With European CE certification, this machine adheres to rigorous quality and safety standards, providing users with peace of mind.

Warranty Extension Available: The provision of extended warranty options demonstrates the manufacturer's confidence in the machine's reliability and longevity.

Material Saving: The ST-ARPM optimizes material usage during the packaging process, contributing to cost savings and resource efficiency.

Full Automation: This feature epitomizes the essence of automation, orchestrating an entire packaging cycle without manual intervention. It enhances efficiency and consistency.

Conclusion

It is important to know the exact working process of the automatic packaging machine. We can foresee that the automatic packaging machine would be more intelligent and widely used in the future.

As a reputable textile machinery manufacturer with a rich history in automation and intelligent manufacturing technology of textile and warehousing equipment, SUNTECH Textile Machinery possesses cutting-edge core technologies that are recognized globally.

SUNTECH’s products cover the textile manufacturing and handling process of almost fabric types, in which pinking machine, non woven machine, beam truck, meltblown machine, fabric cutting machine, motorized beam trolley, beam storage, warp tying machine are the most popular machines and material handling equipment.

SUNTECH Textile Machinery leads the textile industry with our innovation and experience! Quotes and Cooperation are Highly Welcome!