In the world of textile manufacturing, where relentless demand for round-the-clock production is the norm, a significant transformation is underway. Workers often endure grueling shifts, disrupted sleep patterns, and constantly changing schedules. Traditional methods have led to inefficiencies, increased labor costs, and health concerns for employees. But there's a shining beacon of innovation on the horizon – SUNTECH's Motorized Beam Trolley.

Textile factories have historically been plagued by less-than-ideal conditions, including high noise levels, airborne fibers, and unpleasant odors. While modern facilities have improved in terms of cleanliness and ventilation, challenges still persist. Safety measures like protective gear, noise shields, and ergonomic solutions have been introduced, but there's always room for innovation.

Traditional textile manufacturing practices have struggled to keep pace with rising labor costs, leading some companies to shift production to countries with cheaper labor. However, SUNTECH's innovative approach is changing the game by reducing manual labor reliance and improving efficiency.

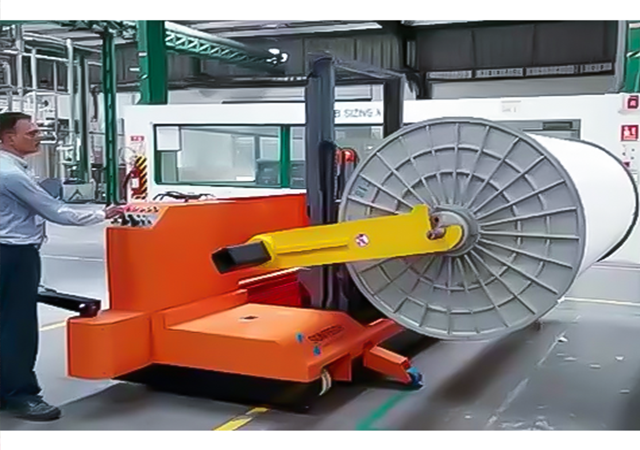

To stay competitive in this ever-evolving landscape, textile manufacturers are adopting advanced machinery and intelligent facilities. SUNTECH's Motorized Beam Trolley is at the forefront of this industry transformation. With over 50 years of design expertise, this technology offers a precise and efficient solution for handling warp and weft warp beams, eliminating the need for manual labor and significantly improving work efficiency.

The benefits are nothing short of remarkable. SUNTECH's Motorized Beam Trolley reduces labor intensity, slashes labor costs, and enhances overall production quality. Its adaptability to various working environments and high loading capacity make it an invaluable addition to any textile manufacturing operation.

SUNTECH's track record speaks volumes, with over 5,000 satisfied customers worldwide and more than 17,000 successful implementations. Users consistently report efficiency gains of over 50%, resulting in annual savings totaling hundreds of thousands of dollars. These results underscore the maturity and effectiveness of SUNTECH's Motorized Beam Trolley in optimizing textile production processes.

Key features of SUNTECH's Motorized Beam Trolley (ST-MBT-05) include:

- Maximum Carrying Capacity: Up to 2500 kgs

- Maximum Lifting Height: Up to 2300 mm

- Rear Shift & Side Shift Capabilities

- Gel Battery for Eco-Friendly and Fast Charging

- Maintenance-Free AC Technology

- Electric Steering System, Operable by a Single Operator

This groundbreaking technology is designed to intelligently transport a wide array of textile components, including fabric rolls, fabrics, weaving shafts, and warp warp beams. Its small footprint, impressive capacity, rapid transportation speed, flexibility, stability, and user-friendly operation make it a game-changer in the industry.

In conclusion, SUNTECH's Motorized Beam Trolley is not just transforming textile manufacturing; it's lighting the way towards a more efficient, cost-effective, and worker-friendly future. For more information on how this innovation can elevate your textile production process and set your business on a path to success, please don't hesitate to contact us.