Fabric relaxing machine, a crucial component of textile manufacturing, offer a multitude of advantages that contribute to the production of high-quality textiles. These innovative devices are designed to alleviate stress and deformation in fabrics, enhancing their overall quality and visual appeal.

Versatility in Fabric Treatment

Fabric relaxing machines are versatile workhorses that cater to a wide spectrum of fabric materials, including silk, linen, cotton, polyester, and nylon. Their utility spans both pre-processing and post-processing stages, making them indispensable in textile manufacturing. Regardless of the fabric type, fabric relaxing machines ensure that stress and deformation are effectively minimized, resulting in improved fabric quality.

Customized Relaxation Parameters

One of the standout features of fabric relaxing machines is their adaptability to meet specific fabric treatment requirements. These machines offer the flexibility to adjust relaxation levels and duration based on the unique characteristics of the fabric material and the processing needs. This customization capability empowers manufacturers to achieve optimal results, ensuring that each fabric is treated precisely as required.

Multiple Relaxation Mechanisms

Fabric relaxing machines employ various mechanisms to achieve their relaxation goals effectively. Two common methods include steam-based relaxation and a combination of heat and mechanical action.

Steam-Based Relaxation: Some fabric relaxing machines utilize steam to relax the fabric. As the fabric passes through a steam-filled chamber, it encounters moisture and heat, inducing relaxation and improved fiber flexibility. Subsequently, the fabric is guided through the machine via rollers or other mechanical means, ensuring an even distribution of moisture and heat throughout. Adjustable tension settings are often available to achieve the desired level of fabric relaxation.

Heat and Mechanical Action: Another type of fabric relaxing machine relies on a combination of heat and mechanical action to relax the fabric. In this variation, the fabric is fed through a series of rollers that apply heat and pressure, causing the fibers to relax. Additionally, a moisture application system may be incorporated to introduce water or steam to the fabric during the rolling process.

Consistent and Reliable Results

Both types of fabric relaxing machines share the common objective of alleviating tension from the fabric. This process facilitates easier handling and prevents undesirable puckering or distortion during manufacturing. Through the combination of heat, moisture, and mechanical action, fabric relaxing machines consistently deliver reliable results across a wide range of fabric types and applications.

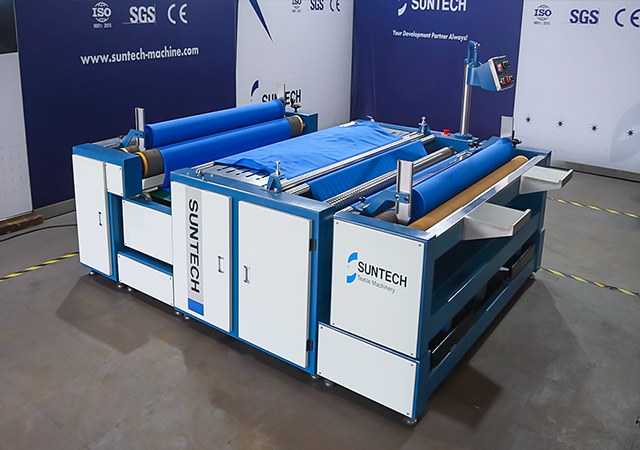

Introducing the Enhanced SUNTECH Roll to Roll Fabric Relaxing Machine (Fifth Generation)

Among the leaders in textile machinery innovation, SUNTECH introduces the ST-FRM-VI(P) fabric relaxing machine, designed to optimize fabric processing. This machine operates by unwinding fabric from two separate rollers, each driven by independent motors and inverters, ensuring tension-free feeding.

What sets the ST-FRM-VI(P) apart is its integrated air-flotation zone, which significantly reduces processing time by effectively relaxing the fabric. The resulting fabric roll is compatible with automatic spreading machines, offering both time and space savings. Furthermore, the Automatic Edge-alignment System ensures precise alignment, limiting errors in edge alignment to just 6mm.

For accurate length counting, the machine offers a margin of error of no more than 0.1m/km, measured in yards or meters. Additionally, an optional Automatic Width Measuring Device is available for online measurements. For precise fabric weight measurement, the Automatic Weight Device can handle weights up to 1000-2000kgs with utmost precision.

SUNTECH Textile Machinery remains committed to continuous innovation and enhancement. In addition to its core fabric relaxing functions, the ST-FRM-VI(P) now includes an additional vibrating table. As the fabric reaches the air duct on the conveyor belt, the vibrating table and airflow operate in unison, gently shaking the fabric to release any remaining tension. This ensures that every inch of the fabric is completely free from tension, preventing subsequent shrinkage during processing.

Established with a dedication to developing, manufacturing, and globally distributing premium textile machinery, SUNTECH Textile Machinery boasts an extensive portfolio that includes two primary categories: the STelego and Fabric Make-up Machine series. With years of technological expertise, SUNTECH's products have gained international acclaim for their exceptional reliability and productivity within the industry.