Introduction

The textile industry is witnessing a remarkable transformation with the integration of AI technology into automatic packing machines. As we explore the innovations showcased at ITMA 2023, it becomes evident that AI-driven automatic packing machines are becoming the go-to solution for manufacturers seeking enhanced efficiency, reduced costs, and improved product quality. In this article, we will delve into the key applications of AI technology in these advanced packing machines and how they are reshaping the fabric packing process.

Streamlining Production with AI

In response to the growing demand for advanced manufacturing processes, almost 50% of ITMA 2023 attendees expressed a keen interest in investing in new machinery and technologies. The integration of AI technology into automatic packing machines has emerged as a game-changer for textile manufacturers.

AI Inspection for Unparalleled Quality Control

Automated fabrci inspection machine powered by AI algorithms and computer vision technology has revolutionized quality control in fabric packing. AI systems can swiftly and accurately detect defects in fabric rolls, ensuring only premium-grade products make it to the market. The ability to identify defect patterns also aids manufacturers in optimizing their production processes, reducing waste, and enhancing overall quality.

Smart Sampling and Taping

AI technology optimizes the sampling and taping process by analyzing data from previous production runs. Machine learning algorithms generate predictive models to determine the ideal number of fabric samples and their precise locations, leading to reduced waste and improved accuracy. Moreover, AI-driven systems recommend the optimal amount of tape required to secure fabric rolls during transportation and storage, safeguarding their integrity.

Advanced Mapping Techniques

AI-driven automatic packing machines create highly detailed maps of fabric rolls using machine learning algorithms and computer vision. These maps identify crucial characteristics, such as size and weight, enabling an efficient packing process that maximizes space utilization and minimizes material wastage.

Precision Labeling for Informed Decisions

The integration of AI technology into the labeling process empowers manufacturers to create comprehensive and accurate labels for fabric rolls. Customers can access detailed information, including fabric type, color, size, weight, and other essential specifications. Informed by this data, customers can make well-informed purchasing decisions, leading to higher satisfaction rates.

Optimal Packing and Sorting

AI technology enhances the packing and sorting process, ensuring the utmost protection for fabric rolling during transportation and storage. By leveraging machine learning algorithms and computer vision, automatic packing machines determine the best packing configuration for each roll. Additionally, AI-powered systems facilitate the automated sorting of fabric rolls based on various criteria, such as fabric type, color, size, weight, and other key characteristics, streamlining the entire process.

Conclusion

The applications of AI technology in automatic packing machines have opened up new possibilities for the textile industry. With greater accuracy, efficiency, and productivity, while simultaneously reducing labor costs and waste, manufacturers are witnessing a significant shift in their production processes. The evolving AI landscape promises even more benefits in the coming years, reinforcing the position of AI-driven automatic packing machines as a crucial component in modern textile manufacturing. As this technology continues to evolve, we can expect to see a continued transformation in the way manufacturers pack fabric rolls, paving the way for a more sustainable and efficient future in the textile industry.

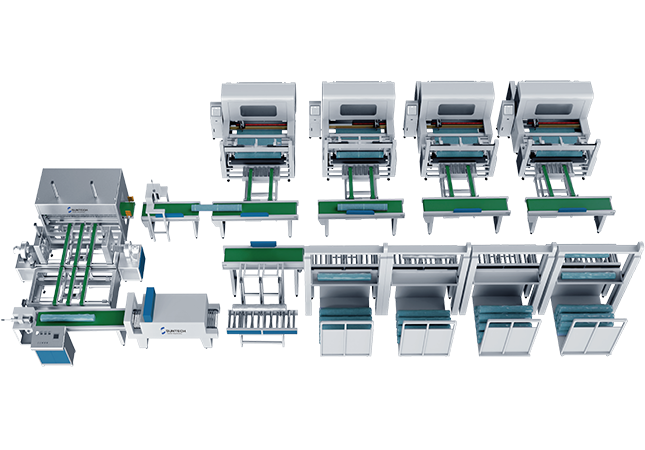

SUNTECH Textile Machinery is committed to the development, manufacturing, and distribution of premium textile machinery since its inception. Our Automated Fabric Roll Packing Line with One-stop Process including Inspection, Sampling, Taping, Maping, Labeling, Packing, Sorting, etc. With years of technological expertise, our products have gained high praise from customers worldwide, recognized for their exceptional reliability and productivity.