Material handling equipment plays a vital role in the manufacturing process by facilitating the movement of materials to enhance production efficiency and minimize downtime. Proper selection and maintenance of such equipment are essential for ensuring accuracy, safety, and the reliable functioning of industrial operations. In this article, we will explore the significance of maintaining material handling equipment and offer insights into how to ensure optimal performance while safeguarding your workforce.

Understanding Material Handling Equipment:

Material handling equipment encompasses a diverse range of tools and machinery, all designed with a common objective: to move materials safely and efficiently. Examples of such equipment include conveyor systems, industrial trucks, and cranes.

The key to keeping material handling equipment in good working condition and preventing accidents lies in its maintenance. Here are some valuable maintenance tips:

Types of Material Handling Equipment:

Conveyors: These systems transport materials from one point to another, coming in roller or belt varieties and powered by electricity or gravity.

Cranes: Cranes are employed to lift and relocate heavy loads, available in both floor-mounted and overhead configurations, and powered by either electricity or hydraulics.

Hoists: Hoists are used to lift heavy loads that cannot be managed by a crane. They come in chain or wire types and are typically electrically powered.

Pallet Jacks: These devices are utilized for moving heavy pallets from one location to another. They can be powered by either an electric motor or a hand pump and have forks that lift the pallets off the ground.

Forklifts: Forklifts are designed to lift and transport heavy loads, powered by internal combustion engines, and equipped with forks to raise the load.

Maintenance Guidelines:

Maintaining your material handling equipment is essential to ensuring a safe and productive workplace. Follow these steps to guarantee your equipment remains in optimal condition:

Regular Inspections: Conduct routine inspections to identify signs of wear or damage. Check all moving parts for undue wear or binding.

Cleanliness: Keep your equipment clean to prevent the buildup of dirt and debris, which can reduce efficiency and increase the risk of accidents.

Lubrication: Lubricate moving parts as needed to ensure smooth operation and prevent unnecessary wear.

Timely Repairs: Replace worn or damaged parts promptly. Waiting for equipment to break down completely can result in costly downtime and pose risks to worker safety.

Follow Manufacturer's Instructions: Always adhere to the manufacturer's guidelines for operating and maintaining your material handling equipment. This helps ensure proper usage and equipment longevity.

In summary, the maintenance of material handling equipment is critical to achieving optimal performance in any industrial setting. Regular inspections, preventive measures, and following manufacturer instructions are key to protecting your equipment and enhancing worker safety. By implementing these practices, your material handling operations will run smoothly, minimizing the risk of accidents and injuries, and maximizing efficiency in your workplace.

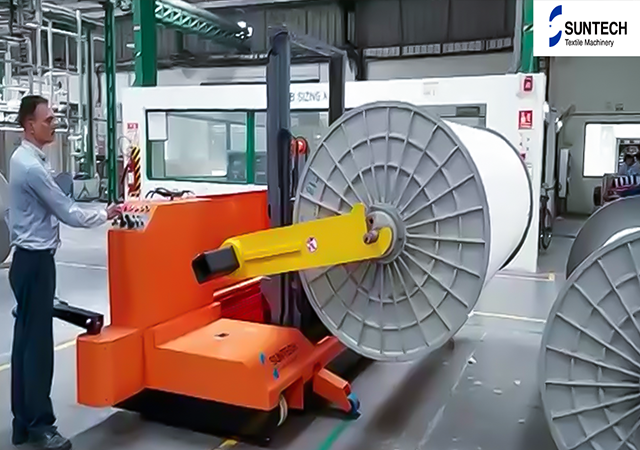

SUNTECH Textile Machinery as a leading expert of material handling equipment provider, has a range of products include motorized beam trolley, warp beam truck, fits different weaving machines, and innovative AGV series. We are continuing to lead the textile industry with its innovative approach and extensive experience. Welcome to contact!