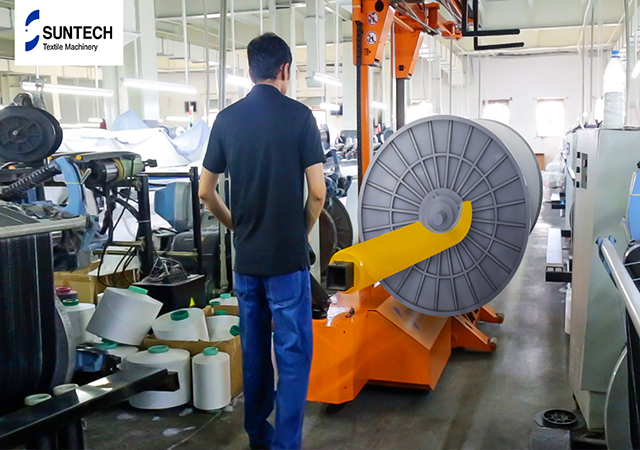

A new innovation in the textile industry is set to change the way we work with beams. The ST-MBT-02I, a highly innovative electric warp beam ltrolley, is designed to make it easier and more efficient for technicians working in weaving factories to transport bottom beams and harnesses from one machine to another. It can handle weave beams weighing up 1800kgs, making it perfect for factories with large machinery that need heavy duty equipment capable of handling heavy loads.

This newly upgraded product, meticulously engineered to meet European standards, combines ease of operation with significant cost-saving benefits, marking a monumental leap forward. By incorporating the ST-MBT-02I into their operations, our customers can achieve a remarkable 40% reduction in costs.

Tailored specifically for bottom beam transporting and insertion in weaving machines, the ST-MBT-02I is equipped to handle weave beams weighing up to 1800kg, with adjustable beam width according to individual requirements. Additionally, it boasts an additional loading capacity of 300kg for the harness. Its versatility extends to compatibility with weaving machines of various sizes, accommodating a normal working width range of 170-340cm without the need for resizing.

Efficient harness integration is facilitated through the standard take-up for the harness frame, along with contact rails, dividing rails, or a complete weave stop motion system. We invite you to explore the features and capabilities of our Motorized Warp Beam Lift Trolley, a testament to our unwavering commitment to excellence in textile machinery.

The motorized trolley comprises three integral systems: the driving system, beam lifting system, and harness mounting system, offering a comprehensive solution for seamless operation.A total of four high-capacity lead acid batteries, each rated at 12 volts and 280 Ah, provides for 24/7 operation with a runtime of up to 8 hours per charge.

FAQ about SUNTECH Motorized Warp Beam Trolley

Q: If the loom width is the same but the brand is different, can the same warp beam lift trolley be used?

A: Yes, you can use the same warp beam lift trolley as long as you determine the distance between the outer wall of the loom. Once we have this information, we will design the warp beam lift trolley based on the largest size.

Q: How do I maintain the battery?

To maintain the battery of the motorized beam trolley, please follow these guidelines:

When the battery power is lower than 30%, it needs to be charged immediately.

The charging time from 30% battery power to fully charged is approximately 8 hours.

Once fully charged, the battery can be used continuously for 3-4 hours with a full load and 6-8 hours with an empty load.

Battery life: We use gel batteries, which have a service life twice as long as general lead-acid batteries. The actual lifespan of the battery depends on the frequency of use and the customer's specific usage, but in general, it can withstand approximately 1000 charge and discharge cycles.

The motors connected to our batteries are all 24V AC motors. However, we can also provide DC motors if required.

SUNTECH Textile Machinery has the range of products encompasses almost all fabric types, including but not limited to motorized beam trolley, beam storage, and fabric inspection machine. SUNTECH Textile Machinery continues to lead the textile industry with our innovative approach and extensive experience. Welcome quotes and cooperation opportunities from you!